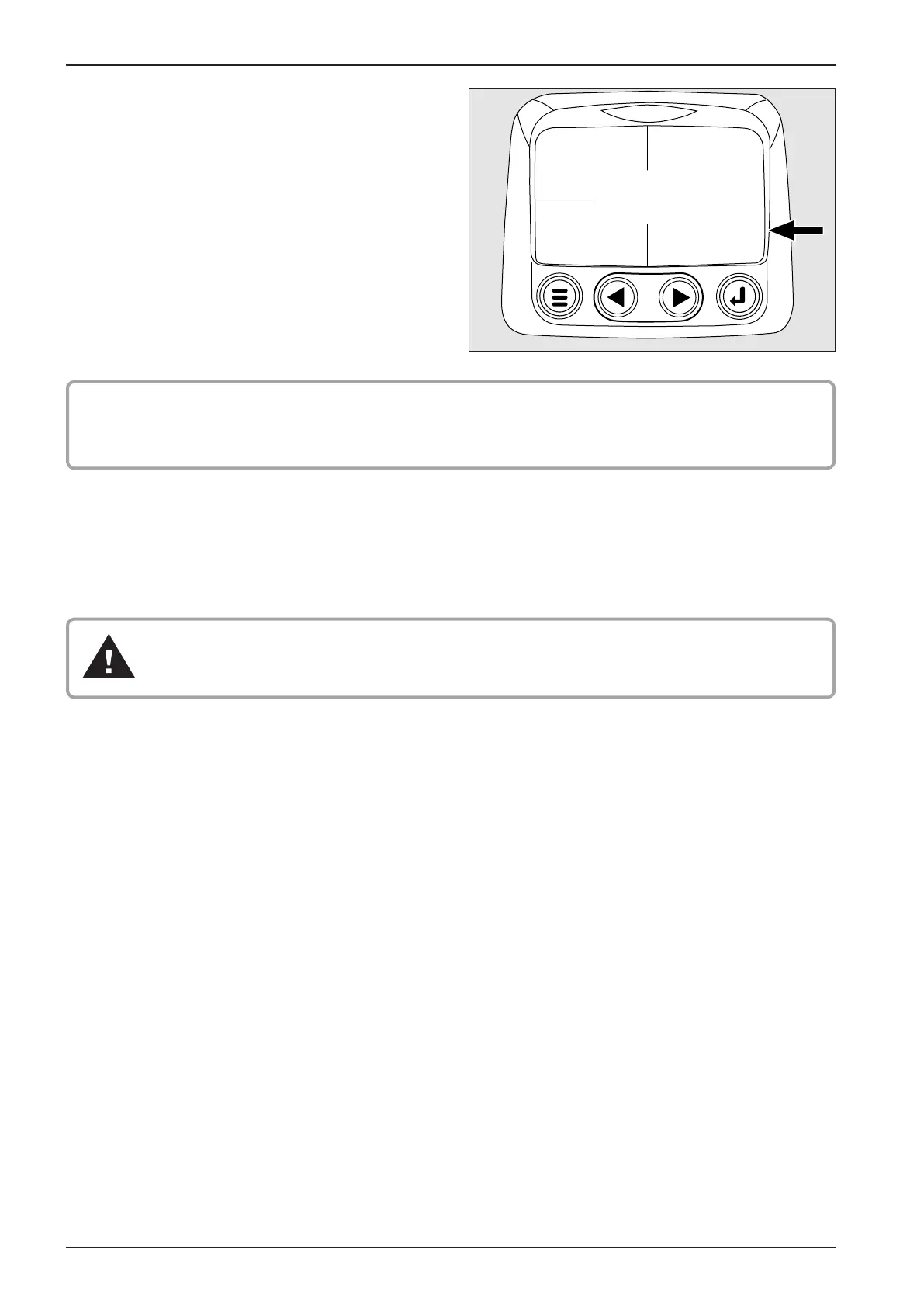

112 ASC 110

20%

FUEL LEVEL

100

ENG HRS

28°C

COOL TEMP

0 RPM

ENG RPM

396313A

3.6. Individual Operations of Maintenance

Carry out lubrication and maintenance on regular basis and re-

peatedly in the intervals as per daily reading on the counter of

hours actually worked.

! CAUTION !

This Manual states only the basic information about the engine, other data are given in the Engine Operation and

Maintenance Manual which is part of the Documentation supplied with the Machine.

Following the rst 100 hours of operation of the new Machine (following a major overhaul) carry out

as per:

3.6.24. Oil exchange in the travel gearboxes

Following the rst 5000 hours of operation of the new Machine (following a major overhaul) carry out

as per:

3.6.26. Checking, adjusting the valve clearance

Tighten the removed or loosened bolts, plugs, threaded joints of the hydraulics, etc. with tightening torque according to the Chart in

par. 3.6.39. unless another value is provided with the respective operation.

Carry out maintenance with the Machine placed on at, paved surface, and secured against any self-

motion, always with the engine o, and key removed from the ignition box and with the wiring cut o

(unless otherwise required).

Loading...

Loading...