SECTION 5 – INSTALLATION

PAGE 5-2 REV. 0 2014-APR-30

Surface Mounting Instructions (Continued)

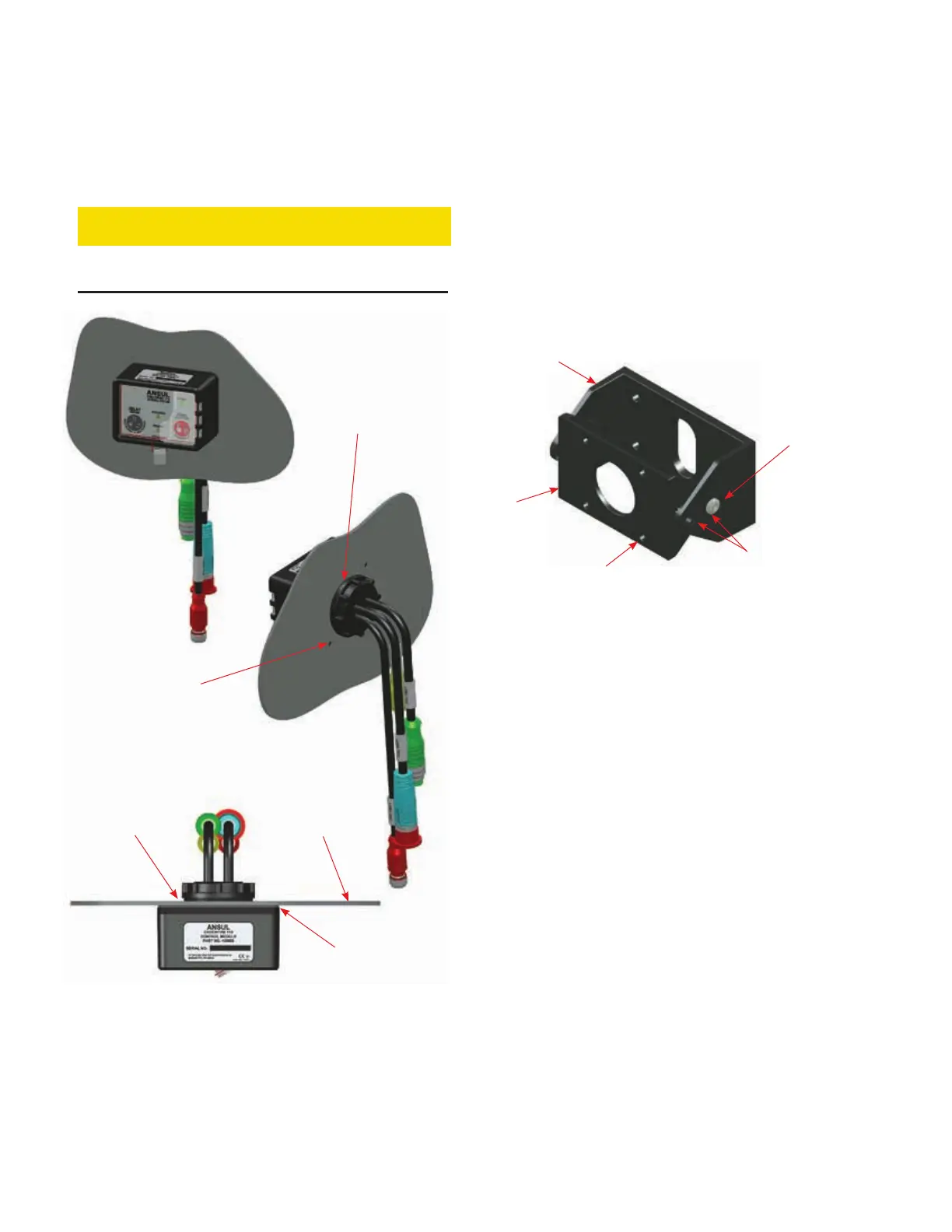

8. Hand-tighten enclosure nut on threaded boss, see Figure

5-3.

CAUTION

Only hand-tighten enclosure nut, do not use mechanical

force such as a wrench.

FIGURE 5-3

SURFACE MOUNT 110 CONTROL MODULE

009205

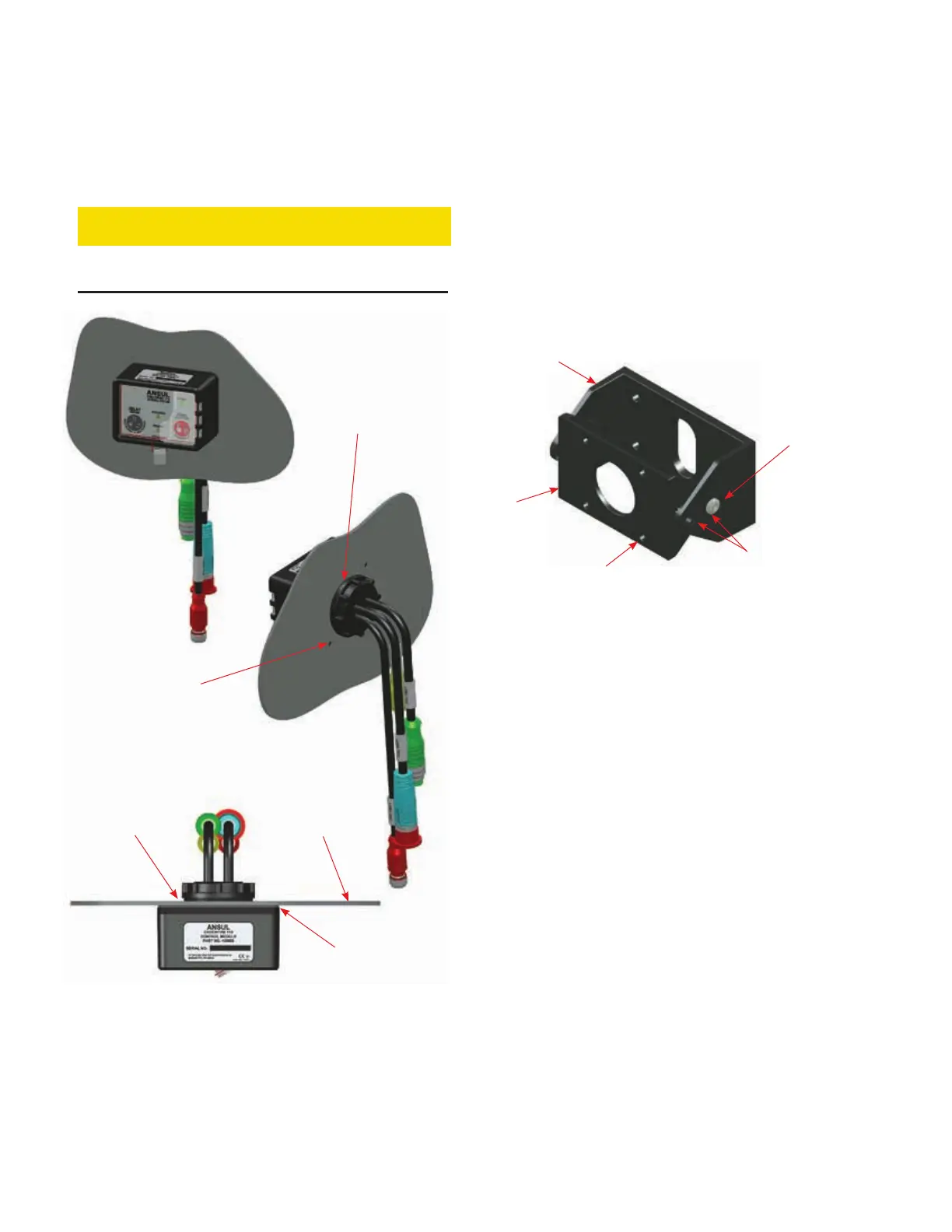

Bracket Mounting Instructions

Bracket mounting requires the CHECKFIRE 110/210 Mount-

ing Bracket (Part No. 439564). The bracket is a two piece,

multi-position bracket for securing the control module in a

variety of configurations. Mount on a flat surface that will prop-

erly support the control module during all vehicle operating and

environmental conditions (e.g. shock and vibration).

The bracket includes a Bracket Base, a Swivel Mount and

two swivel joint screws, see Figure 5-4. The control module

attaches to swivel mount in a horizontal or vertical position on

either side of swivel mount.

FIGURE 5-4

CHECKFIRE 110/210 MOUNTING BRACKET

009181

1. Refer to layout drawing for planned location and determine

a position within the operator’s reach with the best viewing

angle for control module LEDs and easy access to control

module buttons. Verify the location meets approval of the

vehicle owner and/or vehicle service manager. See Figure

5-5 for sample mounting options. Note the positions of

swivel mount and connectors.

CHECKFIRE 110

Detection and Actuation System

HAND-TIGHTEN

ENCLOSURE NUT

INDEX HOLES

(TWO PLACES)

RUBBER

WASHER

MAXIMUM 3/16 IN.

(4.7 mm) THICKNESS

FOAM GASKET

FORWARD AND

BACK CONNECTORS

(FOUR PLACES)

SWIVEL JOINT

SCREW (TWO

PLACES)

BRACKET BASE

SWIVEL

MOUNT

INDEX HOLE

(FOUR PLACES)

Loading...

Loading...