SECTION 5 – INSTALLATION

2014-MAY-08 REV. 02 PAGE 5-7

CHECKFIRE 110

Detection and Actuation System

LINEAR DETECTOR INSTALLATION (Continued)

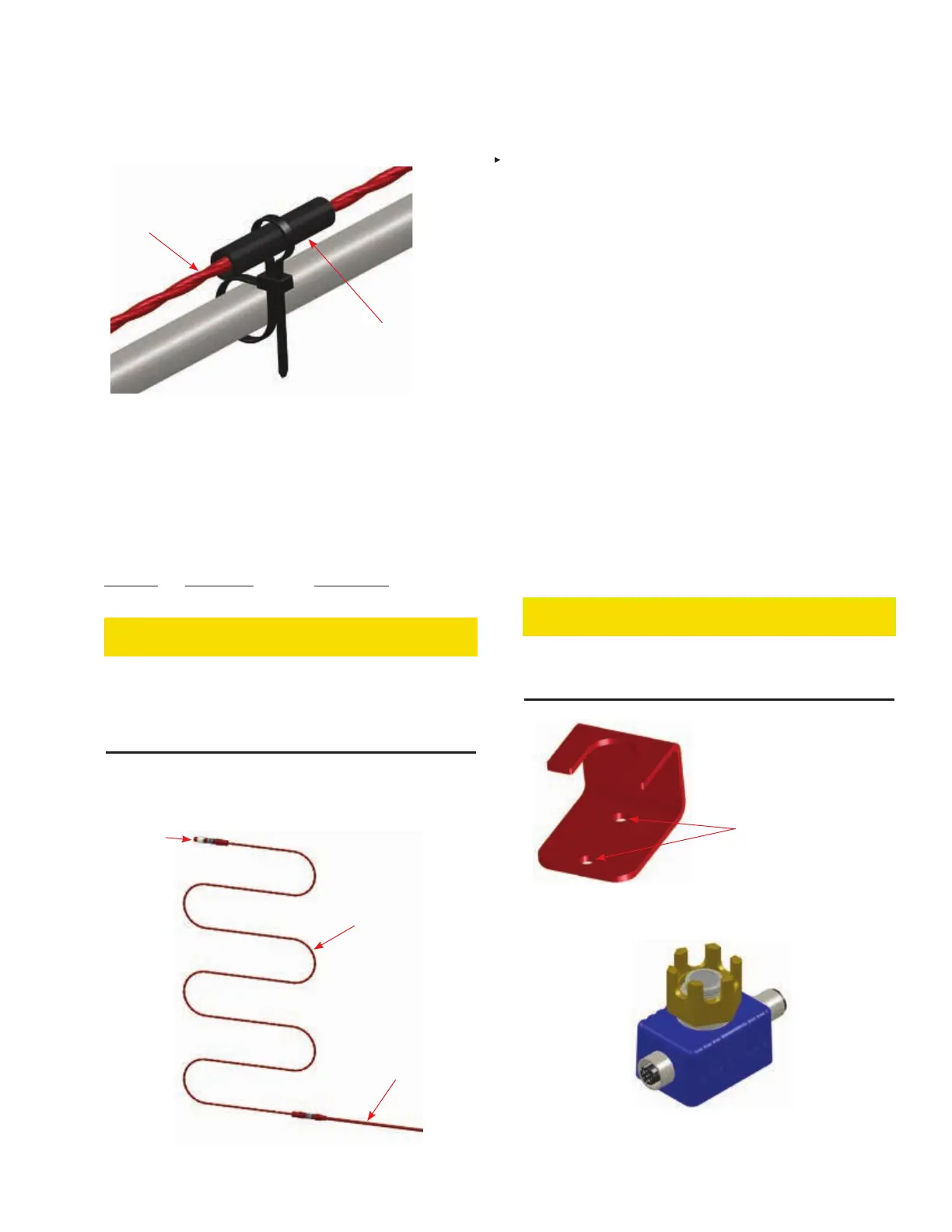

LINEAR

DETECTOR

PROTECTIVE

COVERING

FIGURE 5-15

DOUBLE-LOOP CABLE TIE

009213

5. When a Linear Detector must pass-through a partition it is

recommended to use a bulkhead fitting designed for the

appropriate cable. See Figure 5-14, page 5-6.

Bulkhead Connector

Maximum

Pass-through

Part No. Thickness Cable Type

439404 3/8 in. (9.5 mm) Detection Circuit

CAUTION

Linear Detector must never be routed through a hole or near

sharp edges without being properly protected. Failure to

protect the cable from being cut or abraded could cause a

fault condition or false alarm condition, potentially leading to

a false discharge or detection failure.

6. Install an EOL Device (Part No. 439396) at end of the

Linear Detector, if last device, to complete the circuit. See

Figure 5-16.

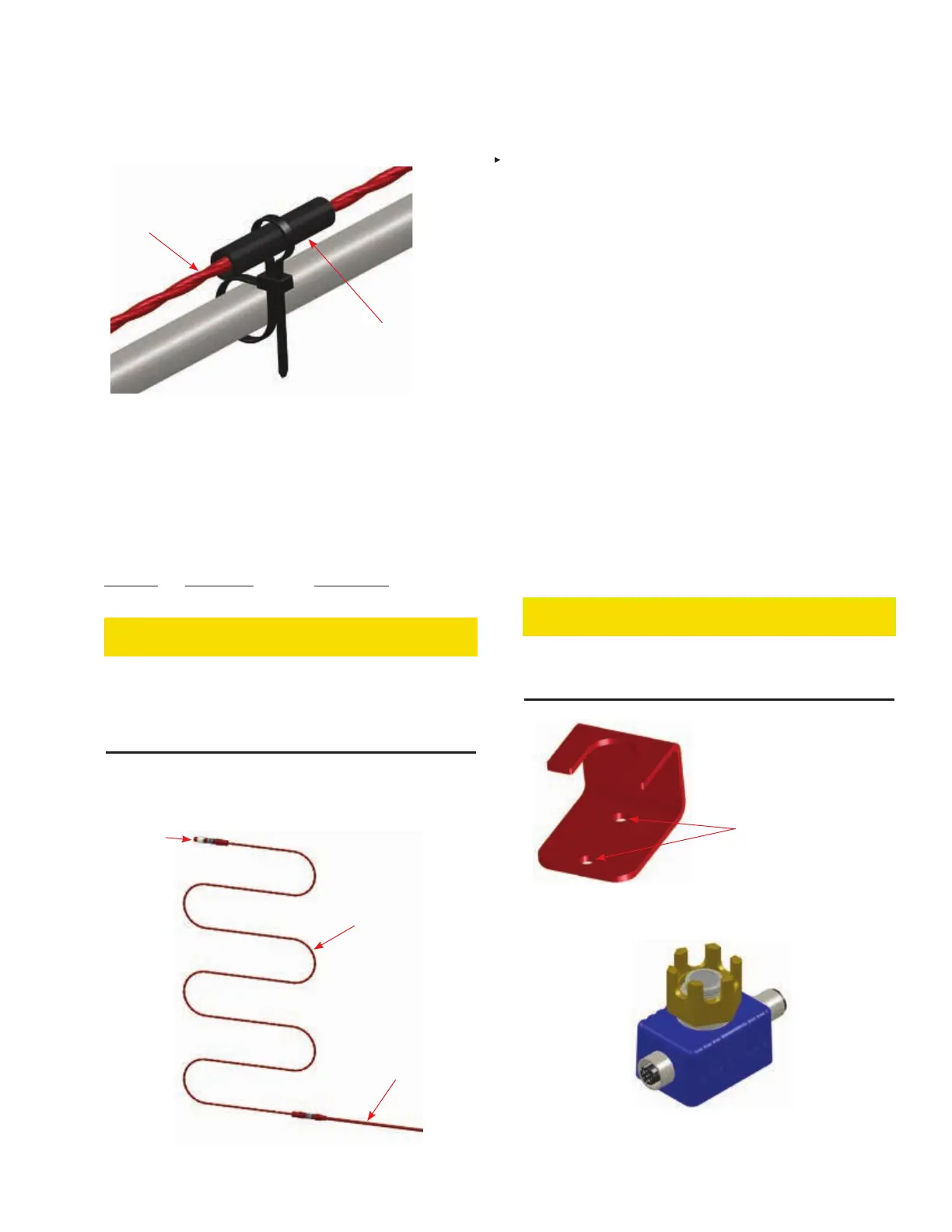

BEND RADIUS

NOT LESS THAN

2.5 IN. (64 mm)

MAIN DETECTION

CIRCUIT

EOL DEVICE

FIGURE 5-16

SAMPLE LINEAR DETECTOR INSTALLATION

009194

SPOT THERMAL DETECTOR INSTALLATION

Mount in a location where detector head points in a downward

position with exposure over the hazard area (refer to layout

drawing).

1. Attach Spot Thermal Detector Bracket securely to mount-

ing surface by welding or bolting with two 1/4 in. bolts of

appropriate length (secure with lock washers and nuts). See

Figure 5-17. Note: When supporting from the vehicle make

certain any support device requiring drilling or welding is

approved by owner or vehicle manufacturer.

2. After securing bracket, remove retaining nut from detector

head and slide detector in bracket. Confirm detector has

male/female connectors in correct position for connection to

detection circuit cable. See Figure 5-18.

3. Place Heat Shield over detector head and loosely install

retaining nut. See Figure 5-19. Note: Remove Heat Shield

to connect Detection Circuit Cables.

4. During final installation, apply a medium-strength thread-

locking compound (e.g. LOCTITE THREADLOCKER BLUE

242) to the base of threaded detector head near the heat

shield.

5. Tighten retaining nut wrench-tight until the retaining nut is

snug. Do not over tighten. Torque not to exceed 25 in-lb

(2.82 N•m).

CAUTION

Over tightening of the retaining nut can damage the detec-

tor. Do not overtighten. Torque not to exceed 25 in-lb (2.82

N•m).

MOUNTING HOLES FOR

1/4 IN. MOUNTING BOLTS

(OR WELD)

FIGURE 5-17

SPOT THERMAL DETECTOR BRACKET

009234

FIGURE 5-18

SPOT THERMAL DETECTOR

009280

Loading...

Loading...