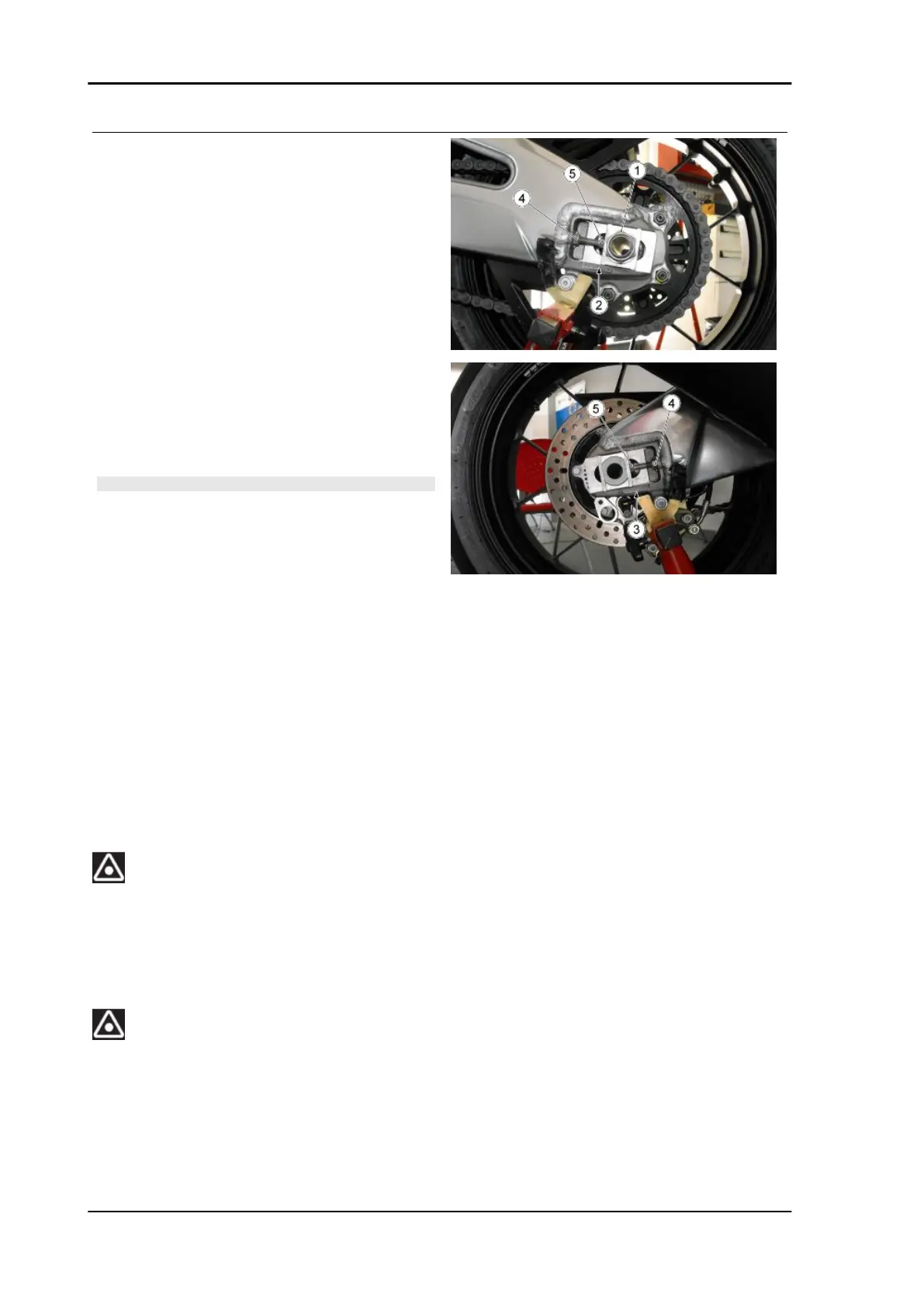

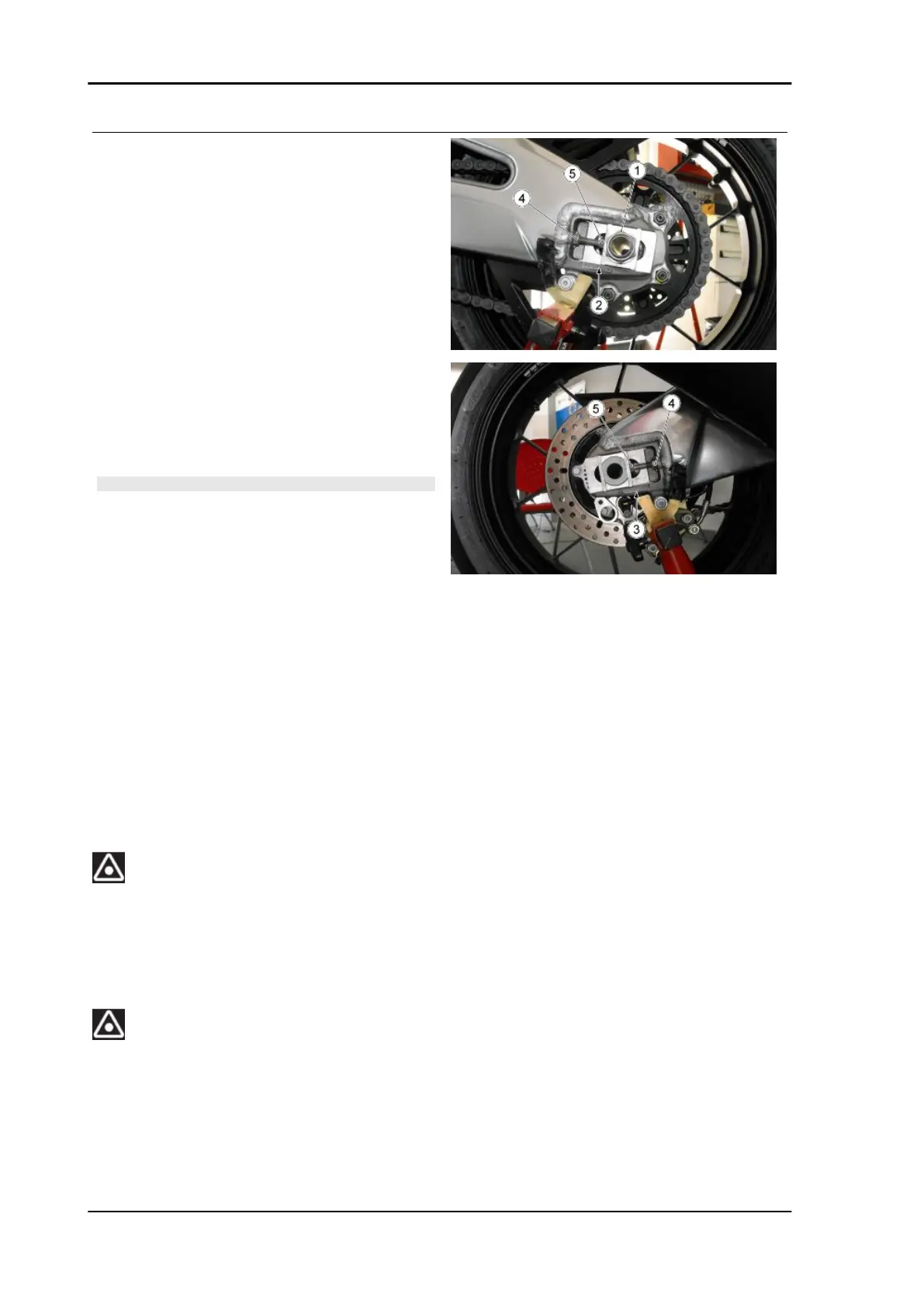

If you need to adjust chain tension after the check:

•

Place the vehicle on its rear service

stand (OPT).

•

Loosen the nut (1) completely.

•

Loosen both lock nuts (4).

•

Actuate on the adjuster screws (5) and

adjust the chain clearance checking

that the references (2-3) match on both

sides of the vehicle.

•

Tighten both lock nuts (4).

•

Tighten the nut (1).

•

Check chain clearance.

CAUTION

WHEEL CENTRING IS CARRIED OUT USING THE IDENTI-

FIABLE FIXED REFERENCES (2-3) INSIDE THE CHAIN

TENSIONER PAD MOUNTS ON THE SWINGARMS, IN

FRONT OF THE WHEEL AXLE.

CHECKING WEAR OF CHAIN, PINION AND SPROCKET

Also regularly check the following parts and make sure that the chain, the pinion and the sprocket do

not show:

•

damaged rollers;

•

loosened pins;

•

dry, rusty, flattened or jammed chain links;

•

excessive wear;

•

missing sealing rings;

•

excessively worn or damaged pinion or sprocket teeth;

IF THE CHAIN ROLLERS ARE DAMAGED, THE PINS ARE LOOSE AND/OR THE SEAL RINGS

ARE DAMAGED OR MISSING, THE ENTIRE CHAIN UNIT (PINION, SPROCKET AND CHAIN)

NEEDS TO BE REPLACED.

LUBRICATE THE CHAIN REGULARLY, ESPECIALLY IF THERE ARE DRY OR RUSTY PARTS.

CRUSHED OR SEIZED LINKS MUST BE LUBRICATED AND RESTORED TO PROPER WORKING

ORDER.

THE DRIVE CHAIN HAS SEAL RINGS BETWEEN THE LINKS, WHICH KEEP THE GREASE INSIDE.

BE EXTREMELY CAREFUL WHEN ADJUSTING, LUBRICATING, WASHING AND REPLACING

THE CHAIN.

CLEANING AND LUBRICATION

Do not wash the chain with water jets, vapour jets, high-pressure water jets and highly flammable sol-

vents.

Chassis TUONO V4 R a-PRC ABS

CHAS - 438

Loading...

Loading...