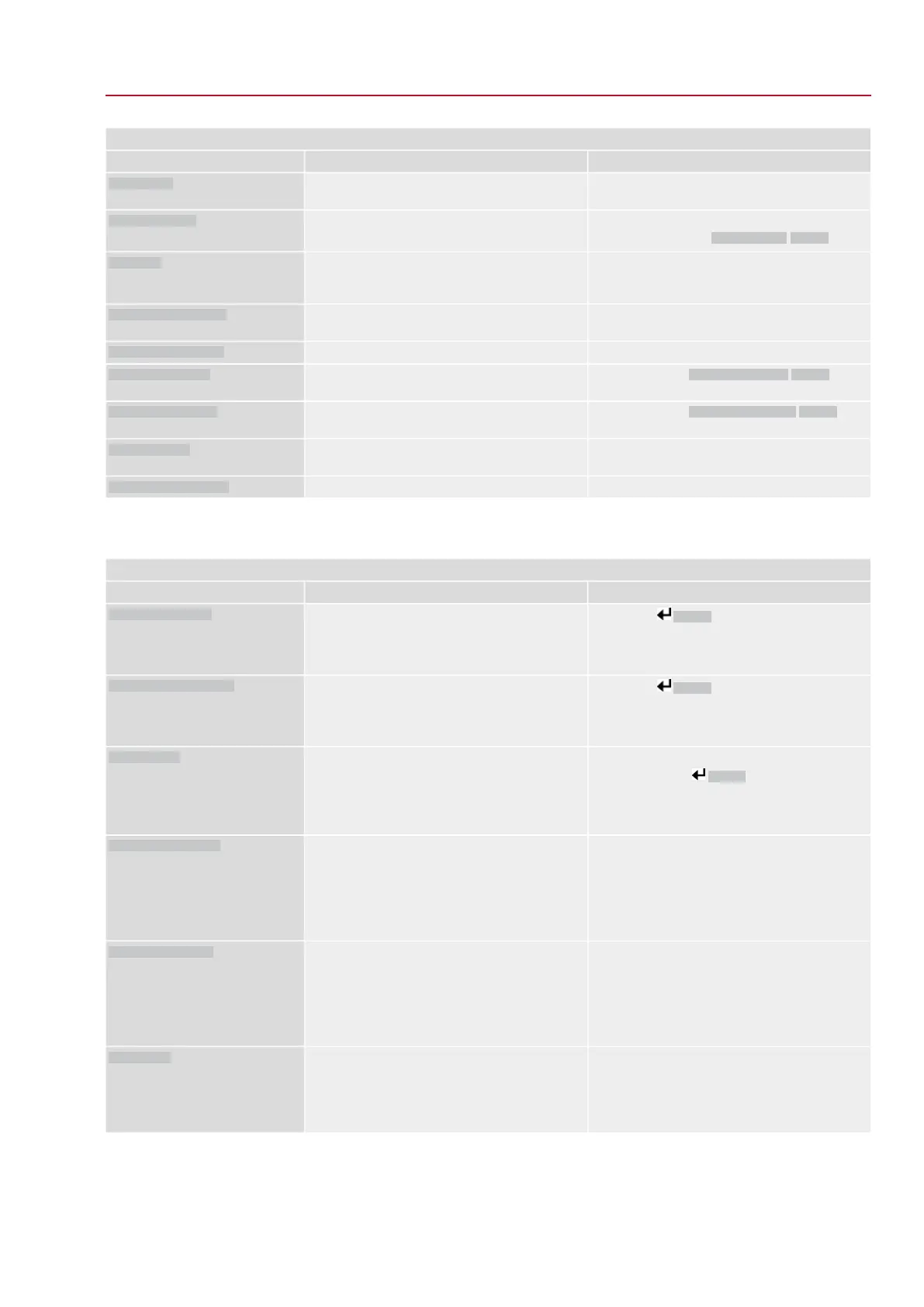

Faults and warnings via status indications in the display

RemedyDescription/causeIndication on display

For indicated value > 0: Press push button De-

tails.

For details, refer to <Not ready REMOTE and

Function check> table.

Collective signal 08:

Indication according to NAMUR recommendation

NE 107

The actuator is being worked on; output signals are

temporarily invalid.

S0009

Function check

For indicated value > 0: Press push button Details

to display a list of detailed indications.

Collective signal 09:

Indication according to NAMUR recommendation

NE 107

Recommendation to perform maintenance.

S0010

Maintenance required

For indicated value > 0: Press push button Details

to display a list of detailed indications.

For details, refer to <Faults and Failure> table.

Collective signal 10:

Indication according to NAMUR recommendation

NE 107

Actuator function failure, output signals are invalid

S0011

Failure

Table 29:

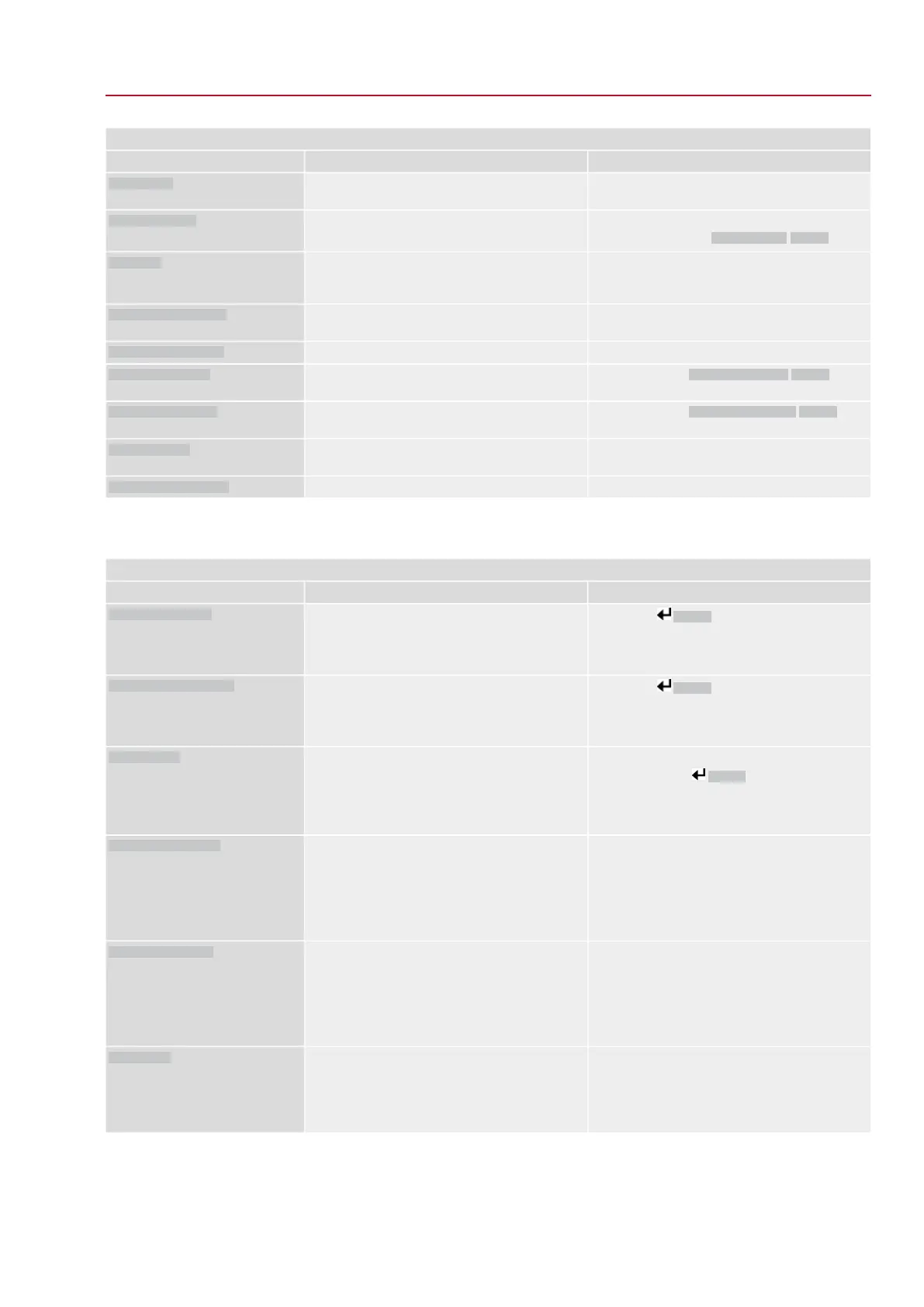

Warnings and Out of specification

RemedyDescription/causeIndication on display

Press push button Details to display a list of indi-

vidual indications.

For a description of the individual signals, refer to

Manual (Operation and setting).

Collective signal 06:

Possible cause:

Configuration setting is incorrect.

The device can still be operated with restrictions.

Config. warning

Press push button Details to display a list of indi-

vidual indications.

For a description of the individual signals, refer to

Manual (Operation and setting).

Collective signal 15:

Device warnings

The device can still be operated with restrictions.

Internal warning

Check 24 V DC voltage supply.The external 24 V DC voltage supply of the controls

has exceeded the power supply limits.

24 V DC external

●

Check modulating behaviour of actuator.

●

Check parameter Perm. run time M0356, re-set

if required.

Warning on time max. running time/h exceeded

Wrn op.mode run time

●

Check modulating behaviour of actuator.

●

Check parameter Permissible starts M0357, re-

set if required.

Warning on time max. number of motor starts

(starts) exceeded

Wrn op.mode starts

Verify signals:

●

Setpoint E1

●

Actual value E2

●

Actual process value E4

●

Check connection to master.

●

Check (clear) status of master.

The failure behaviour is active since all required

setpoints and actual values are incorrect.

Failure behav. active

Check wiring.Warning: Loss of signal analogue input 1

Wrn input AIN 1

Check wiring.Warning: Loss of signal analogue input 2

Wrn input AIN 2

Check setpoint signal.Warning: Loss of signal setpoint position

Possible causes:

For an adjusted setpoint range of e.g. 4 – 20 mA,

the input signal is 0 (signal loss).

For a setpoint range of 0 – 20 mA , monitoring is

not possible.

Wrn setpoint position

The warning indications are automatically cleared

once a new operation command is executed.

●

Check valve.

●

Check parameter Perm.op. time, manual

M0570.

The set time (parameter Perm.op. time, manual

M0570) has been exceeded.The preset operating

time is exceeded for a complete travel from end

position OPEN to end position CLOSED.

Op. time warning

Measure/reduce ambient temperature.Temperature within controls housing too high.

Wrn controls temp.

Set time.Real time clock has not yet been set.

Time not set

Replace button cell.Voltage of the RTC button cell is too low.

RTC voltage

Check actuator (PVST settings).Partial Valve Stroke Test (PVST) could not be suc-

cessfully completed.

PVST fault

69

SQV 05.2 – SQV 14.2 / SQRV 05.2 – SQRV 14.2 Control unit: electronic (MWG)

ACV 01.2 Non-Intrusive Profinet Corrective action

Loading...

Loading...