4-/5-Gas Measuring Instruments Unit AVL 4000

5-12 Service Manual

5.7 Cleaning the Condensate Part of the 4/5-Gas Bench

This part should be cleaned every six months or once a year, especially if the instrument

is often used to test non-catalytic-converter vehicles or 2-stroke engines. It should also be

cleaned if the condensate end of the pump starts to leak.

Accessories:

− Cleaning hose with filter

Length l = 0.5…1 m; diameter d

i

= 6 mm and hole diameter max. 1 mm

(the best way to clean it is by drawing through a 50/50 % mixture of air and

cleaning fluid)

− Connector

Hose fitting for connecting the condensate discharge hose and the probe hose

− Cleaning fluid

approx. 2…5 l (water with non-foaming detergent)

Procedure

• Switch the instrument off.

• Open the hose connection between the condensate filter and check valve.

• Connect the cleaning hose with filter straight to the check valve.

• Clean the probe hose and probe with clean, oil-free compressed air.

Caution: the probe hose must not be connected to the exhaust gas tester!

• Connect the probe hose and the probe to the condensate discharge hose (on the

pump) using a connecting piece

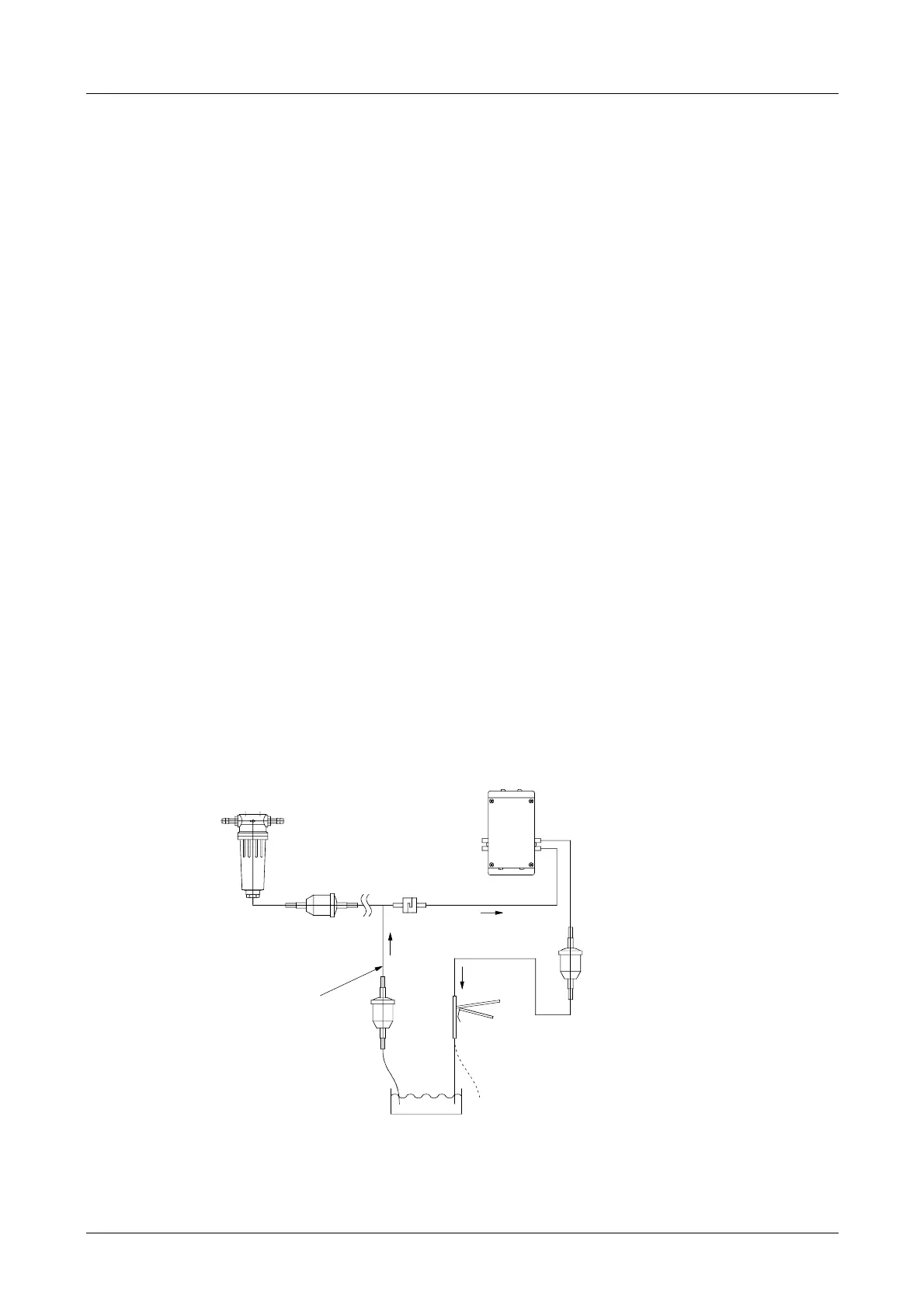

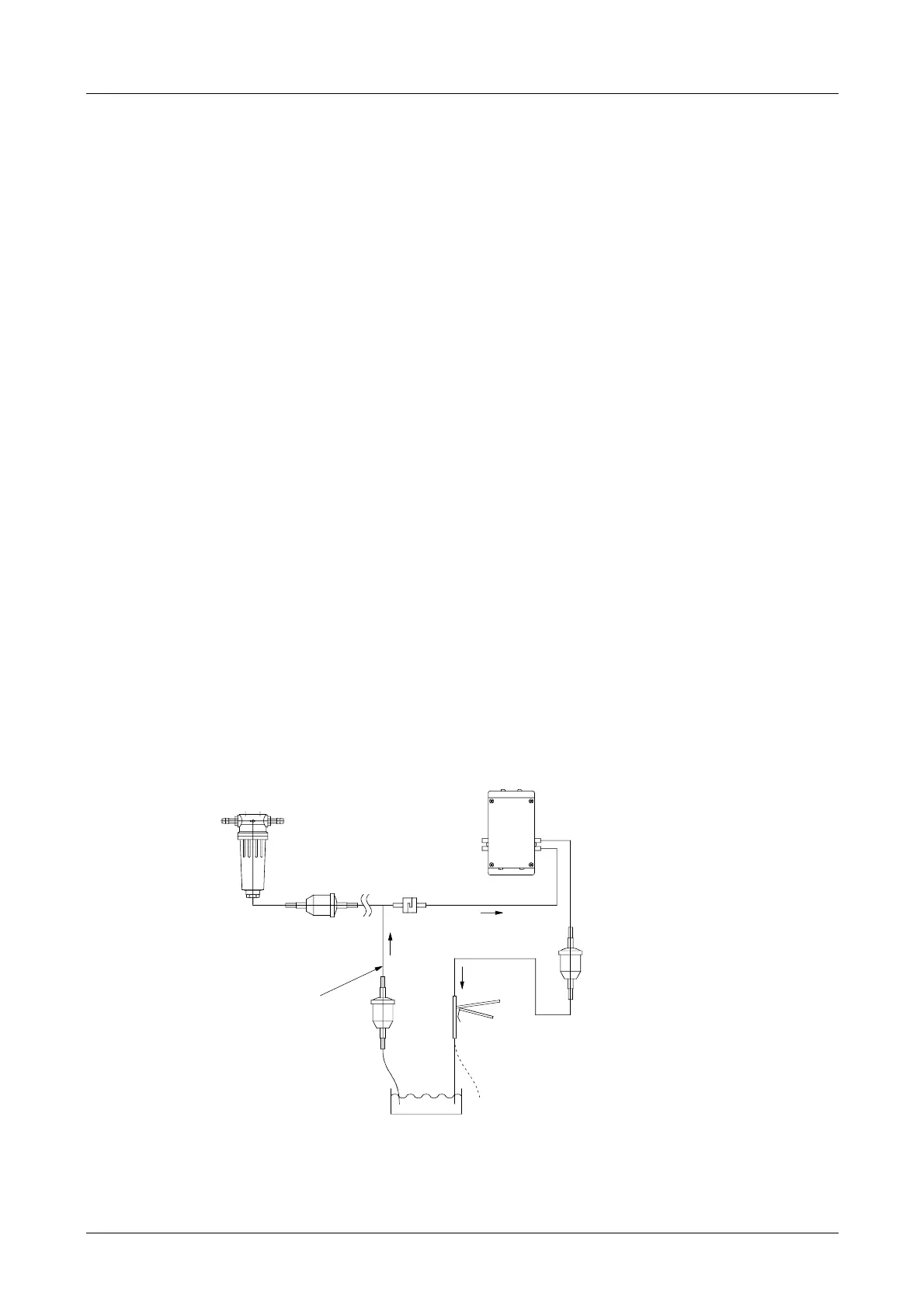

• Now set up a rinsing fluid circuit as shown:

1

2

3

4

5

6

7

8

9

10

Fig. 5-8

1..... Cleaning hose with aperture

2..... Filter

3..... Check valve

4..... Pump

5..... Connecting piece

6..... Probe hose

7..... Probe

8..... Cleaning fluid

9..... Condensate filter

10.....Condensate collector

Hole

Loading...

Loading...