4-11

Chapter 4. WIRING

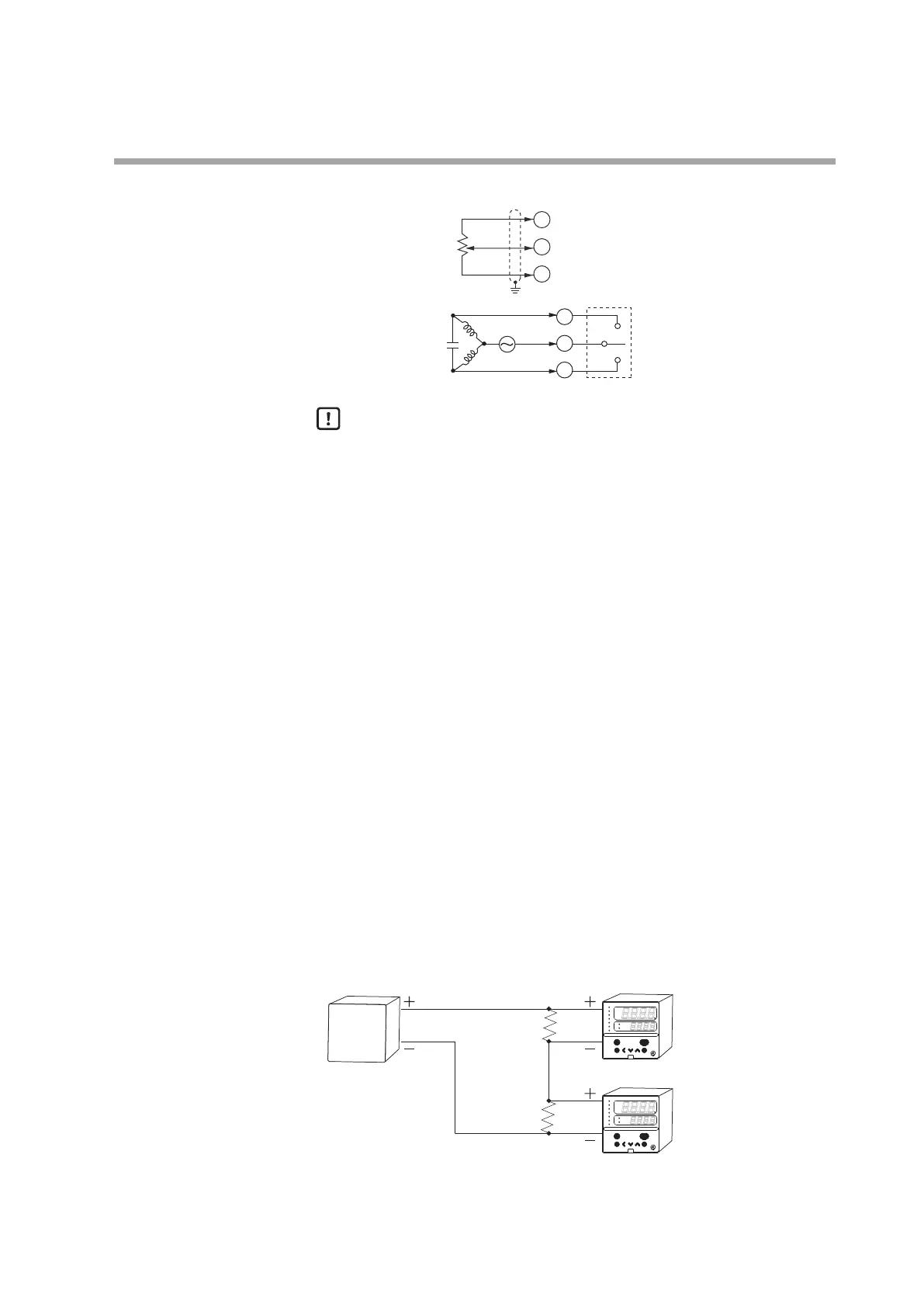

Connection method for the motor drive relay output (R1)

7

8

9

YOpen

Close

T

G

MFB

CLOSE

OPEN

13

14

15

Motor drive relay

Handling Precautions

• If connecting a 100 or 200 V AC motor to the motor drive relay output,

use an external auxiliary relay.

• Do not wire in the same duct for the motor drive terminals 13, 14, 15 and

the MFB input terminals 7, 8, 9 and also do not use 6-core cable.

Doing so might cause a malfunction due to motor start-up noise.

• Avoid setting the PID control such that the output excessively repeats

ON-OFF operations.

Doing so might shorten the life of the built-in relay.

If [

C59

: Motor long life mode] is set at “1,” the number of relay operations

can be reduced with almost no influence on the control results.

• When [

C57

: Position proportional type] is set at “2” or “3,” connections

to MFB terminals 7, 8 and 9 are not necessary. (This is the case of control

without a feedback function.)

• When [

C57

: Position proportional type] is set at “0” or “1” with motor

feedback function (MFB enabled), be sure to execute [

C60

: Motor adjust].

• When [

C57

: Position proportional type] is set at “2” or “3” without

motor feedback function (MFB disabled), be sure to input the value of

[

C63

:Motor full close-full open time] exactly.

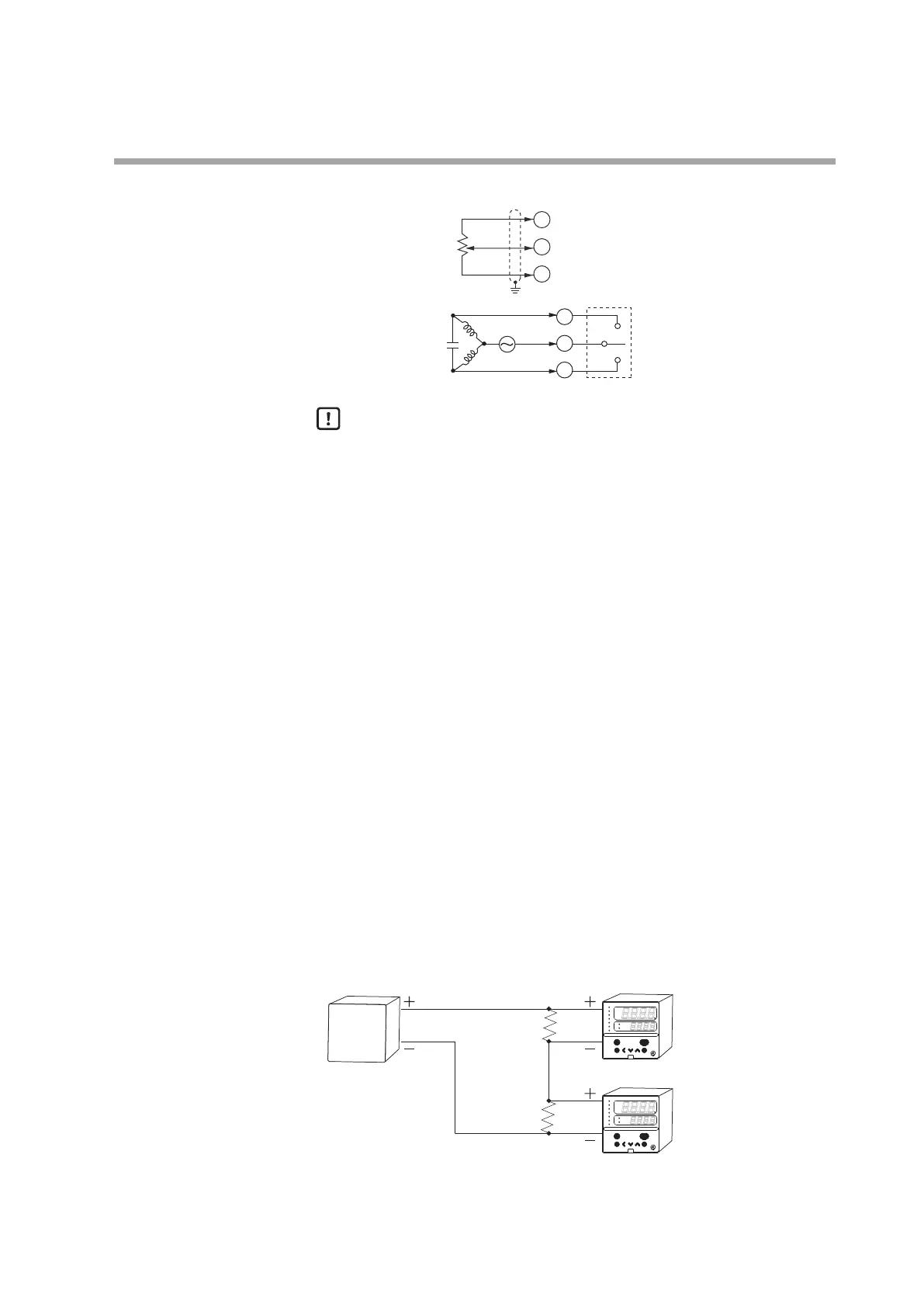

Connection with current-input type controllers

When the power to this controller is turned off, the current input circuit is cut off.

If multiple current-input type SDCs are connected in series and you want to turn

them on/off individually, convert them to voltage input by adding resistors (No.

81401325, sold separately) to the circuit.

rdy

man

ev1 ev2 ev3 ot1 ot2

para

mode

pv

sp

SDC15

1 to 5 V

250 Ω

250 Ω

4 to 20 mA

1 to 5 V

SDC35/36

SDC35/36

Current output device

para enter

display

mode

pv

out

sp

ot2

ot1

ev3

ev2

ev1

rsp

man

SDC36

para enter

display

mode

pv

out

sp

ot2

ot1

ev3

ev2

ev1

rsp

man

SDC36

Loading...

Loading...