Azbil Corporation Installation

MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector 2-7

2.4.1: Determining the fastening torque

The following table shows the fastening torque for each pipe bore.

CAUTION

The correct fastening torque must be used to prevent leakage. To avoid damage to

the detector, do not exceed the listed fastening torque.

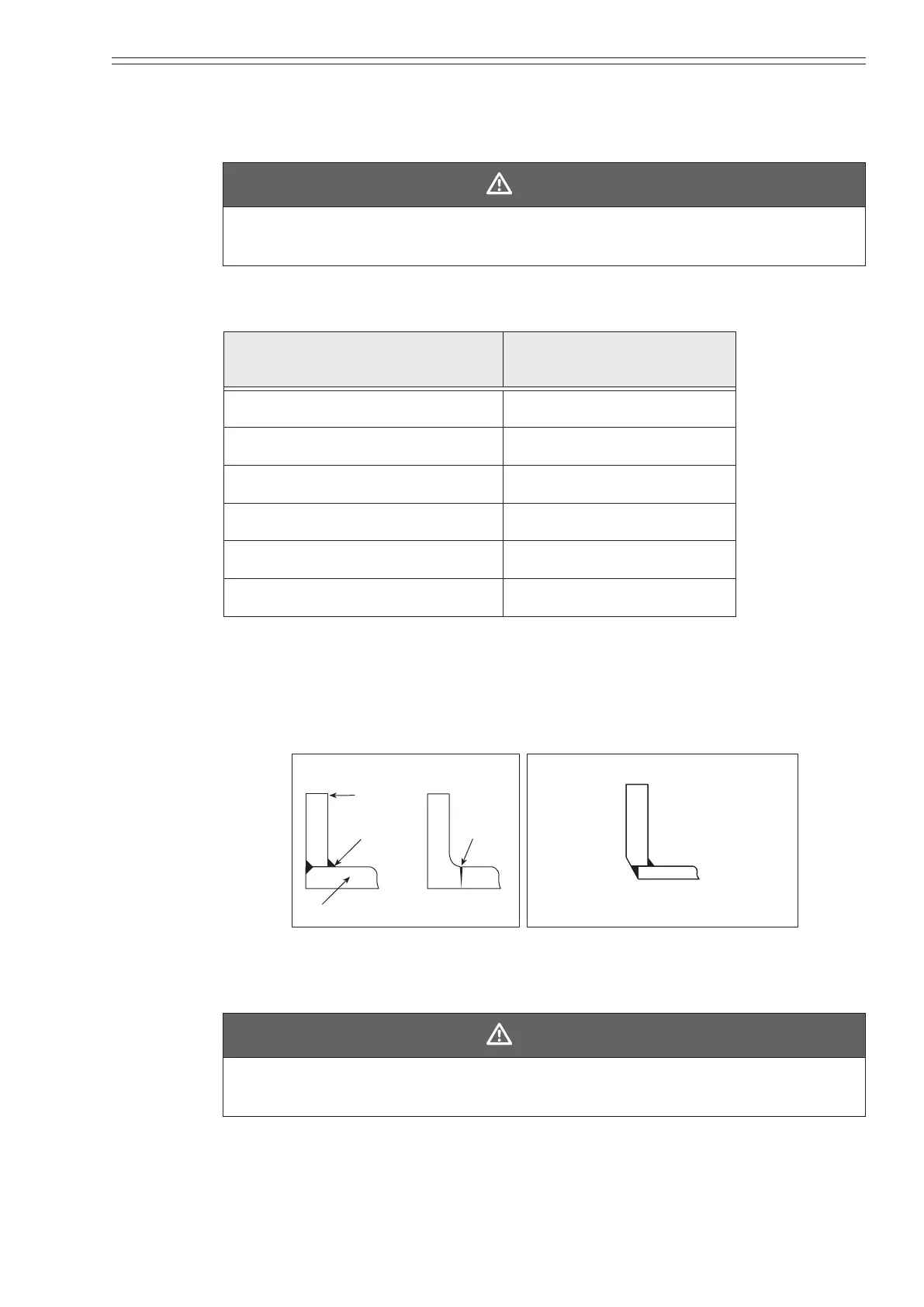

Table 2-1 Fastening torque for wafer detectors

Nominal detector bore diameter

mm (inch)

Fastening torque

N•m (ft•lb)

2.5 - 15 (0.1 - 3/8) 13 - 18 (9.6 -13.3)

25 (1) 20 - 30 (14.8 - 22.1)

40 - 80 (1½ - 3.1) 30 - 50 (22.1 - 36.9)

100 (4) 50-70 (36.9 - 51.6)

125 - 150 (5 - 6) 80 -100 (59.0 - 73.8)

200 (4) 90 -100 (66.4 - 73.8)

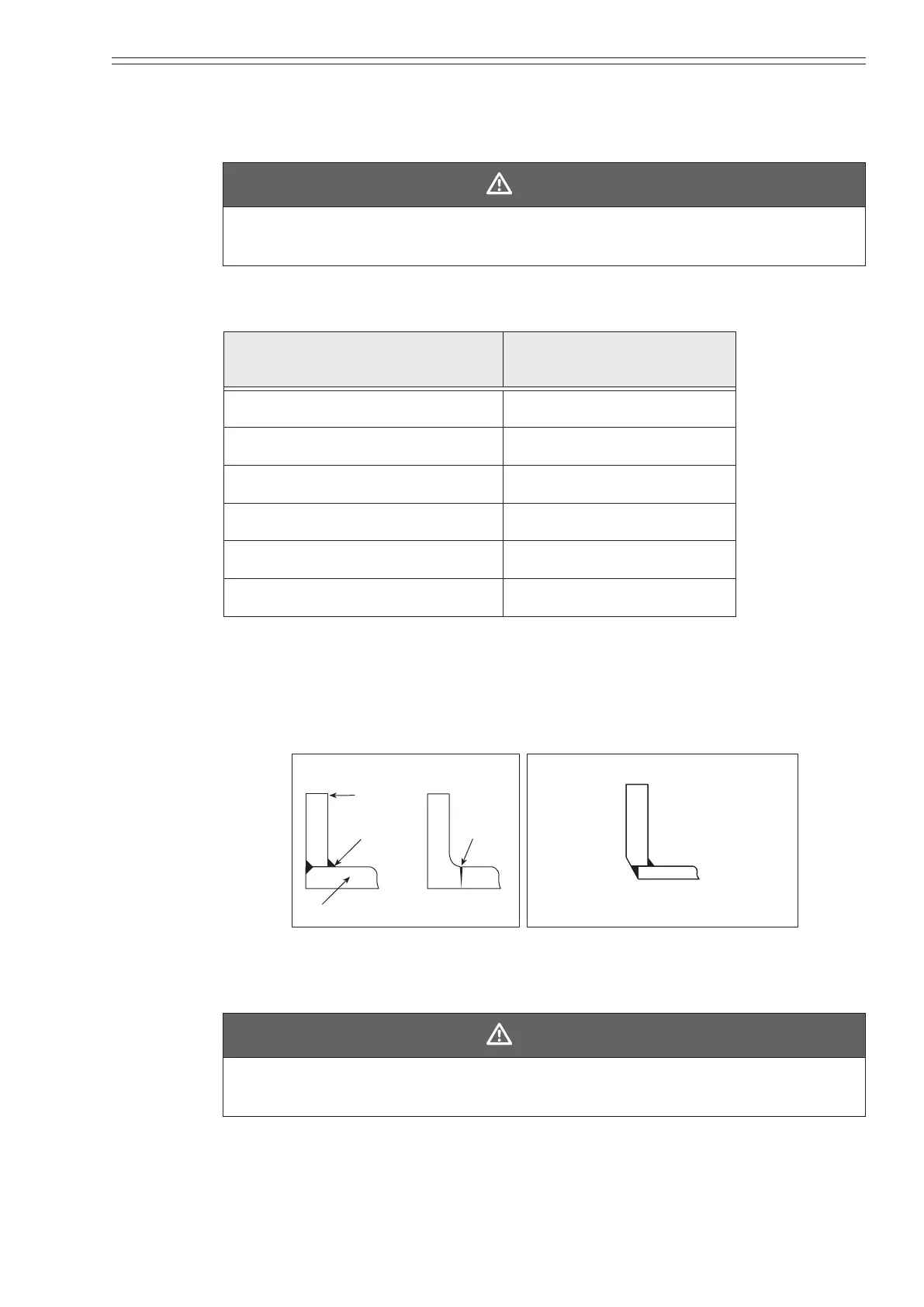

2.4.2: Selecting the ange shape

The anges used for installation should maximize the area of contact with the gasket.

(The liquid could leak because of the

small area of contact with the gasket.)

O Acceptable X Unacceptable

Flange

Welding

Pipe

Welding

Figure 2-6 Flange Shapes

CAUTION

Before installing the detector, make sure that the pipe is exactly straight and

centered. Any irregularity could cause leakage or other hazards.

Loading...

Loading...