Installation Azbil Corporation

2-4 MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector

2.3.1: Detector position

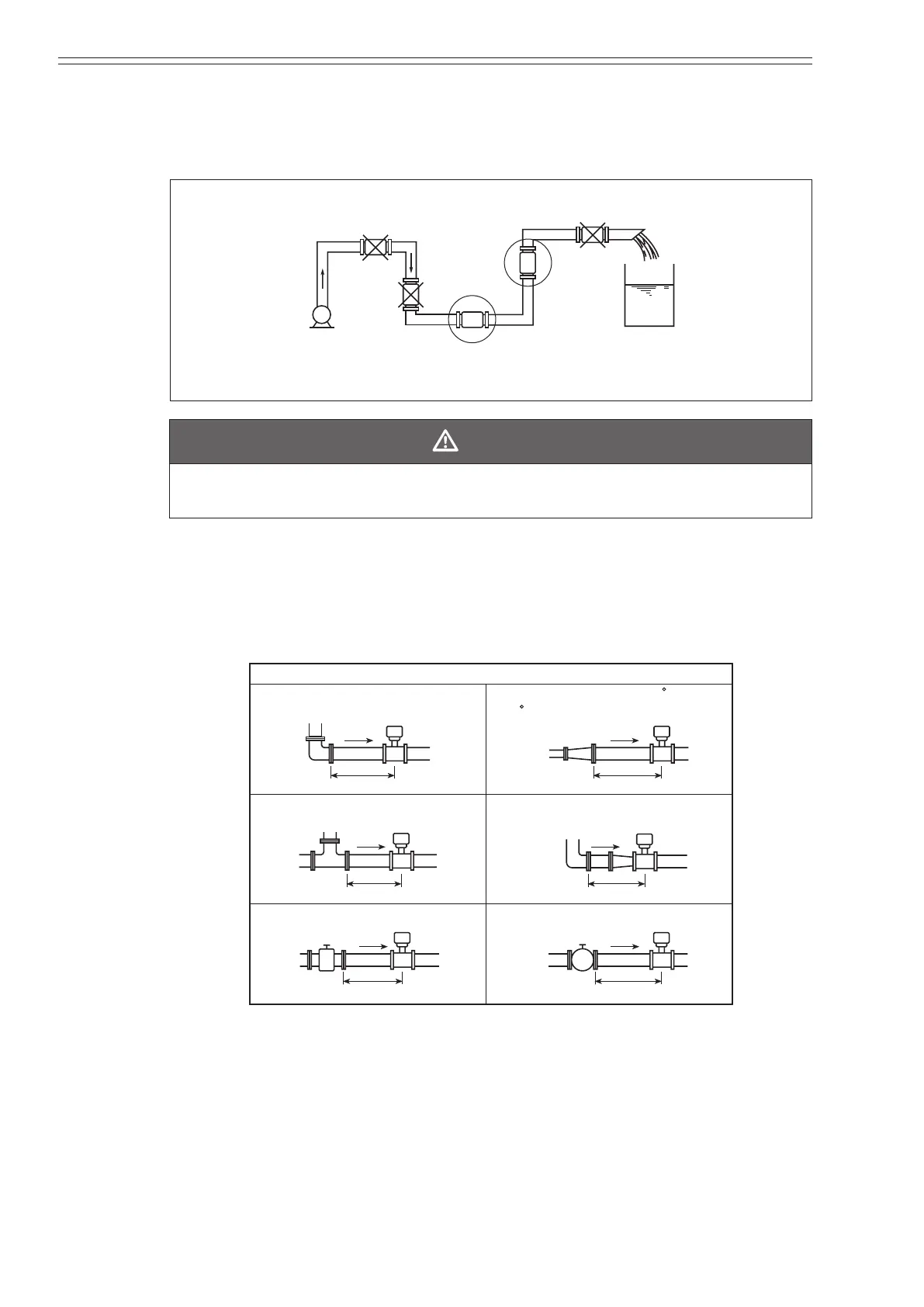

• Position the detector so that its inner detector passage is continuously lled with

the uid being measured. The following gure provides examples.

Bad

Air is easily trapped -

may not ll with uid

with uid

Good

Figure 2-1 Detector placement

CAUTION

The detector must be positioned as shown by the circled areas in the gure shown

above. If the pipe is not lled, output errors will occur.

• When measuring high viscosity uid, connecting the pipe to a vertical detector is

recommended (in order to secure an axial symmetrical ow).

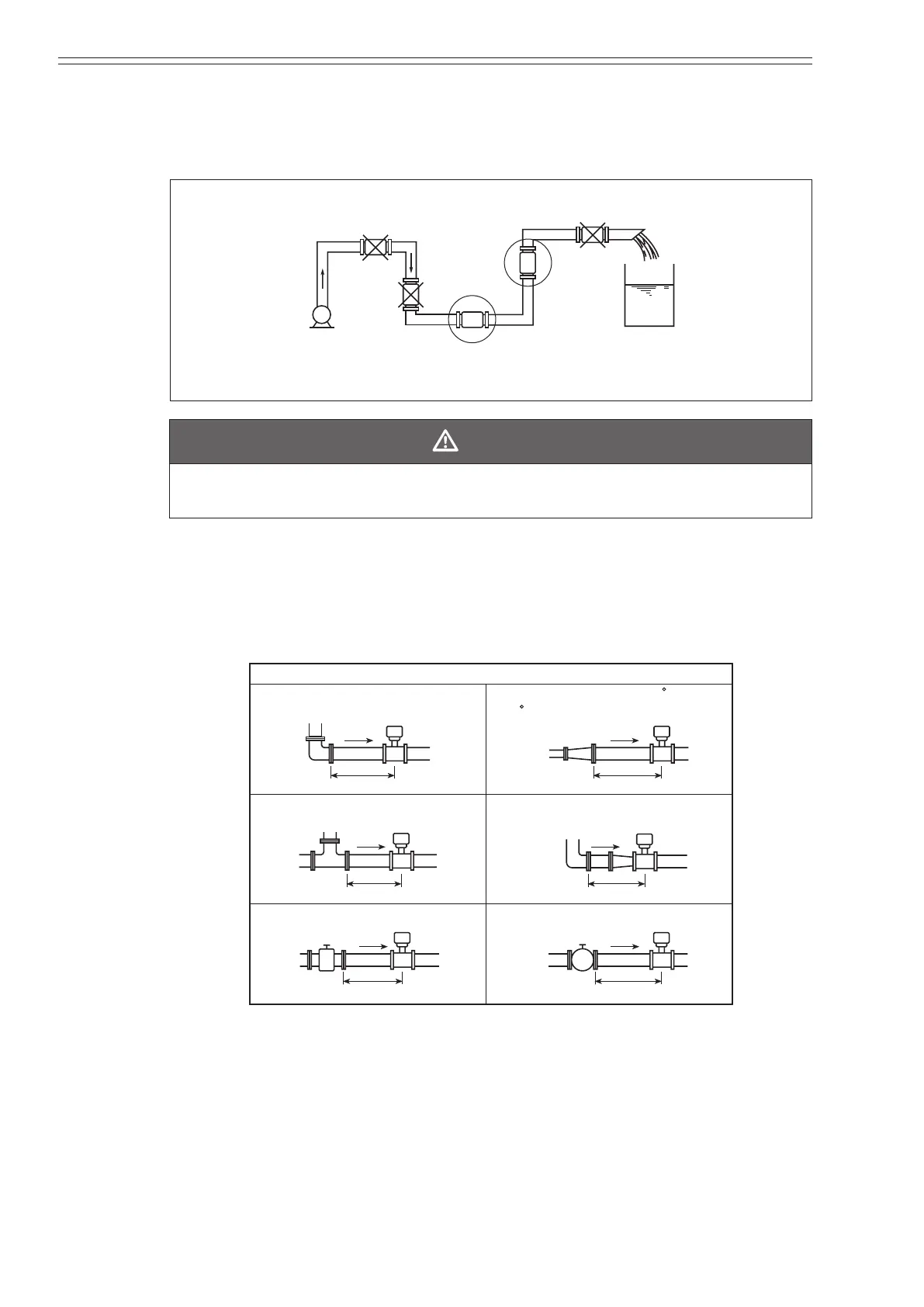

• Install a straight pipe section on the upstream side of the detector. The following

gure shows the length of the straight pipe section (D = nominal bore diameter of

the detector).

Upstream

> 5D

T-joint

Gate valve (Completely open)

Diffuser with cone angle >15

(<15 Considered straight pipe section)

Concentrator

(Considered straight pipe section)

Any type of valve

Right angle joint

Detector

> 5D

Detector Detector

> 10D

Detector

> 5D

Detector

> 5D

Detector

> 5D

Figure 2-2 Straight pipe section on upstream side of detector

• Although a pipe section is not necessary on the downstream side, secure a section

of at least 2D if eccentric ow appears.

• Select an installation site where there is no major pulsation or vibration (away

from a pump).

• Make sure that there is adequate space around the detector after installation to

perform maintenance.

Loading...

Loading...