Code: IU.01.09.0007

Version / Revision: 6.001

Page: 63 de 143

Ultrasonic washer

Model: E0201

• Pay attention to the lengths of the lumens to process. It is correct to validate your process with the

Performance Calibration Protocol to determine the dimensions of the light compatible with the

cleaning process in the equipment.

The Ultrasonic washer is a team whose purpose is to clean the loads to be processed. Do not replenish

the need for a disinfection cycle in a thermal disinfectant so that this material is in conditions of use or

to be sent to a sterilizer.

The Ultrasonic washer does not clean the "dead end" lumens.

It is not recommended to carry out the cleaning process in electronic materials that are not airtight and/

or that are sensitive to process temperatures.

10. Cleaning cycles

Each cycle carried out by the Ultrasonic washer is designed to achieve a reduction in the superficial succession of

the load, which allows for the later use of these material materials processed in subsequent processes.

10.1 Cycle phases

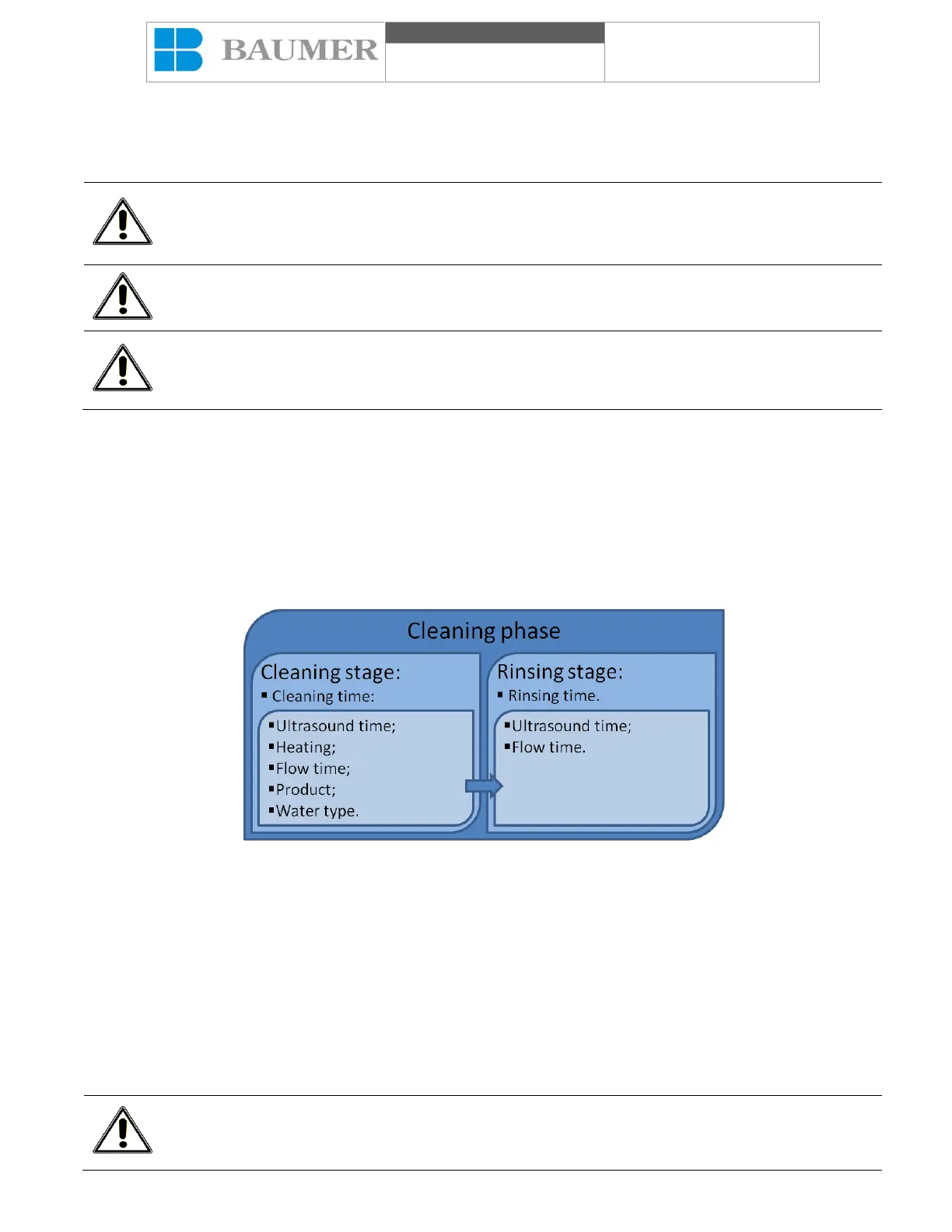

The cycle may have up to 3 cleanliness phases formed as shown in the following image:

Figure 2 – Cleaning phase parameters

10.1.1 Cleaning stage

In addition to being able to qualify within the cleanliness phase, the cleanliness step is responsible for eliminating the

greater part of the succession of the load to be processed. If you can enable:

• The type of water used for cleaning: filtered or purified;

• The time of cleaning;

• Ultrasonic time: time of ultrasonic;

• Flow time: descripted time schedule;

• Product: program the desired volume;

• Hot water.

If enabled, the flow and ultrasound will alternate during the programmed time. It is important that the

shortest period of time in the bone systems is less than the time of cleanliness so that there is enough

time to carry out both actions.

Loading...

Loading...