50

1. Use the 20*20 criteria to the area less than 20*20; 50*50 inspection criteria to the area

20*20≦A<50*50; etc.

(Particle/Blemish/Color Spot)

1.1 Definition of surface A, B, C refer to 6.2

1.2 Blemish around the logo must be equal or smaller than 0.05 mm

2

1.3 Bubble on the surface is to be reject.

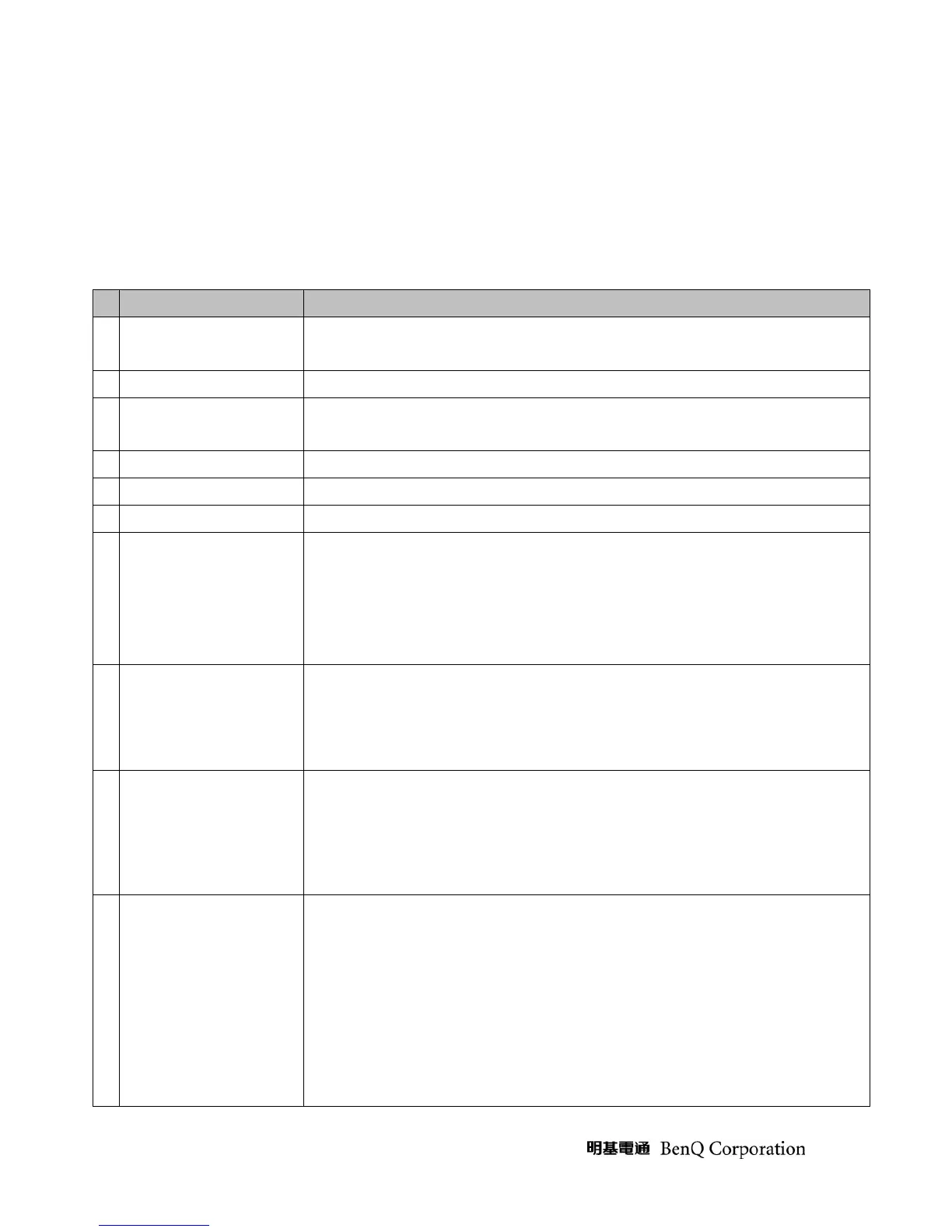

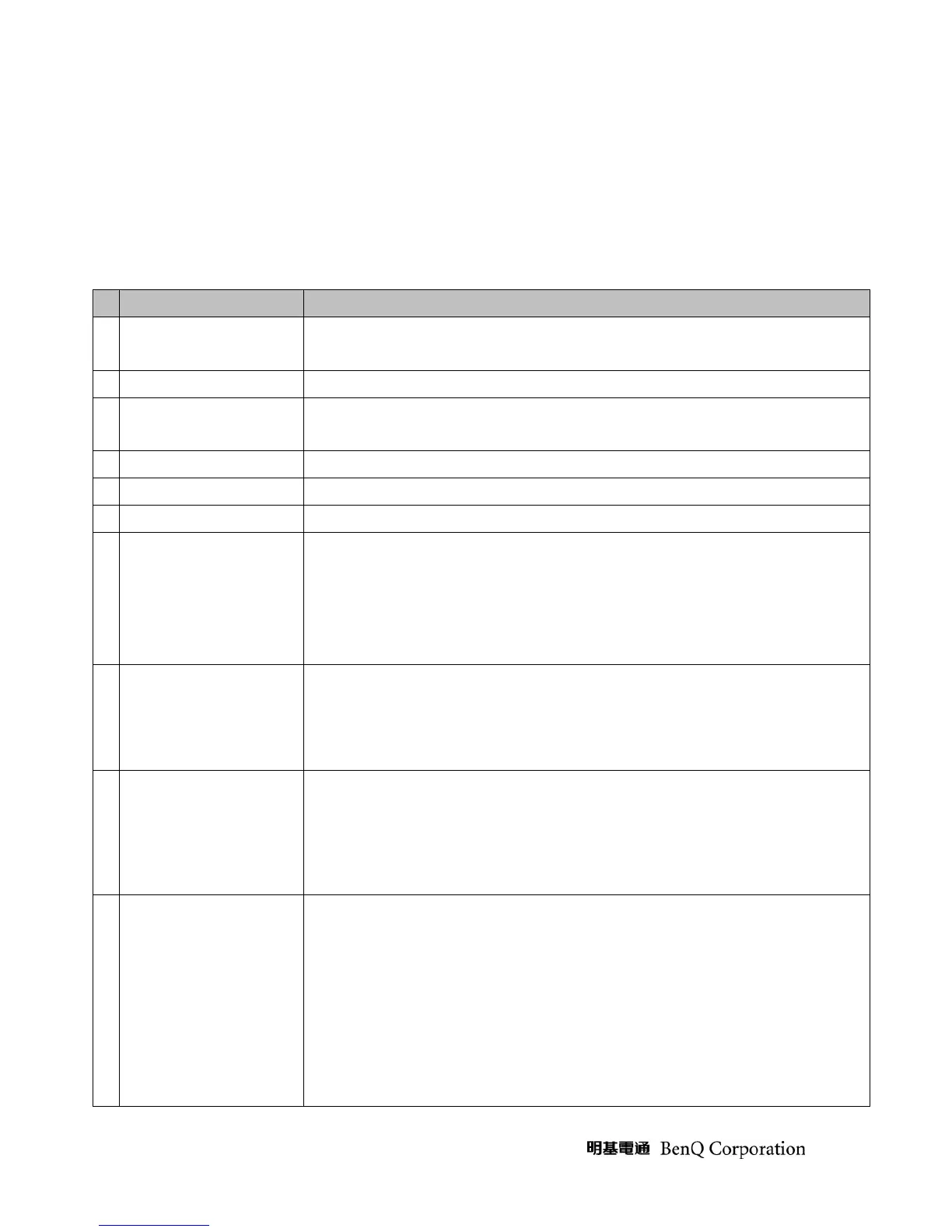

TABLE 2 :(General Product of plastic outlook inspection standard)

No

Shrinkage A region: No Shrink. With gloves, no feeling of sink when touching the surface

B/C region: not obvious

2 Run, Texture, Gloss No obvious non-uniformity

3 Welding Line/Knit Line When scratching on it, there’s no feeling of obstruction. Also, there should not

be obvious difference in gloss nearby it.

4 Ejector Mark Reject

5 Label/screws shortage Reject

6 Material shortage Material shortage is not allowed to impact structure strength and surface

7 Chromatic aberration (Painting): ΔE<=2; L<=1.5 ; Δ A,B <= 0.6

(Paint, aluminum).

ΔE<=2 L<=1.0; Δ A, B <= 0.6

(Paint, non-aluminum)

(Raw material) : ΔL,A,B<=0.6 ,ΔE<=0.75

8 Printing Printing must not have incomplete printing, break off, overlap, uneven

thickness, excessive ink, printing misalignment (1mm), printing slanting &

crooked (<0.3mm)

Printing color must be comparable to color chip and sample.

9 Logo of panel sticker Printing must not have incomplete printing, break off, overlap, uneven

thickness, excessive ink, printing misalignment (1mm), printing slanting &

crooked (<0.4mm)

Printing color must be comparable to color chip and sample.

10

Scratch/Nicks Side A:

(W < 0.1mm , L < 3mm): Only 1 this kind of scratch is accepted

W < 0.1mm , L < 3-5mm No this kind of scratch is accepted

Side B:

W < 0.15mm, L< 3mm Only less than 2 this kind of scratch is accepted

W < 0.15mm , L < 3-5mm Only 1 this kind of scratch is accepted

Side C:

W < 0.2mm , L < 1mm Only 4 this kind of scratch is accepted

Loading...

Loading...