BestCode Next Series 8 Technical Manual October 2022 Page 210 of 290

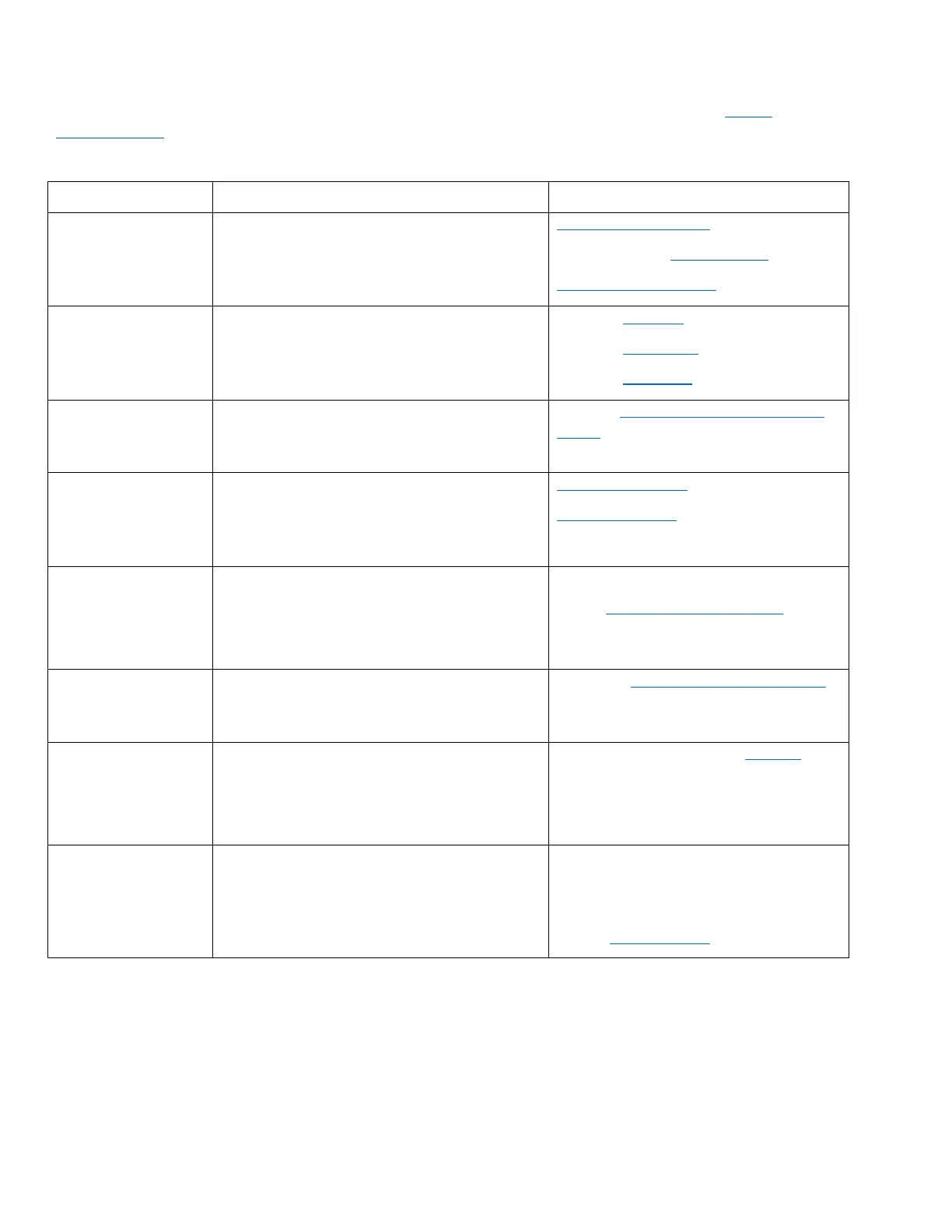

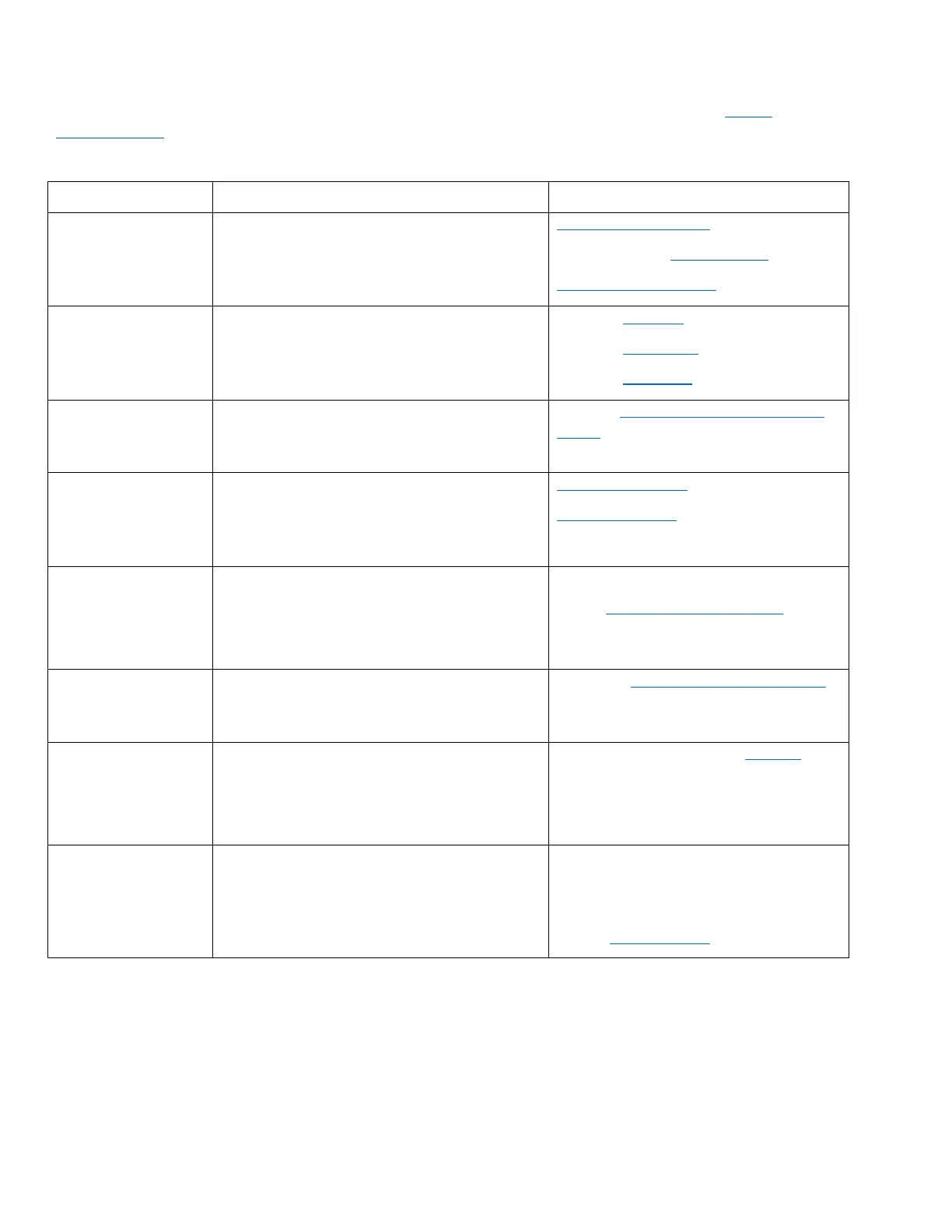

Phase Troubleshooting

The phasing of the Next Series 8 is necessarily sensitive, as it controls much of the print accuracy. Therefore, it is possible

for a number of issues to cause a Phase Fault. Aside from the normal Phase Fault resolutions listed in the Prompt

Resolution Guide, below are listed common causes and solutions.

Printer is poorly

configured

The printer is set up is such a way that the Service

settings are causing Phase Faults to occur. This

can include Pressure, Modulation, Charge, Print

height, and even message setup.

Install Newest Firmware (01.05.01.19+)

Reset machine to default settings

Calibrate the Modulation

Flow is low at the

nozzle.

Can be caused by restriction on the Ink inlet path

for the drop generator or a leaky bleed valve.

Both reduce the jet velocity and disrupt the ability

to phase drops properly.

Check the Jet Speed

Check the Nozzle Flow

Check the Bleed Flow

Erratic RPS causing

pressure fluctuation

Air being drawn into the pump causes cavitation

and varying pressure in the system. Will disturb

jet velocity and cause phasing issues.

Check for Loose Connections on the pump

circuit.

Small nozzle clog is enough to change the droplet

shape but not move the jet out of the gutter. The

strange drop shape will cause issues with

collecting phase data.

Backflush the Nozzle

Replace the Nozzle

Thick or thin ink can cause poor modulation.

Viscosity should be between 3.0 – 6.0 cP for inks

targeted at 4.5 cP, and 1.8 – 3.8 cP for inks set at

2.8 cP.

Check ink viscosity

Review Viscometer troubleshooting

Poor grounding of the machine is a prime

electrical culprit when looking for non-fluidic

causes of Phase issues.

Review the system grounding information.

Check the connections to the circuit board.

Printhead Signal – J27 and Charge Yellow -J33 are

directly related to phase.

Follow Safety instructions for Servicing the

printer.

Clean connections with Isopropyl alcohol

and dry thoroughly before reconnecting.

Ink droplets must be formed for the phase to be

measured. Issue could be related to CPU 300V

circuitry, cabling, or Drop Generator

Clean J34 Modulation with Isopropyl alcohol

and dry thoroughly before reconnecting.

Replace Coax Cable

Replace Drop Generator

Loading...

Loading...