CT-600-2 19

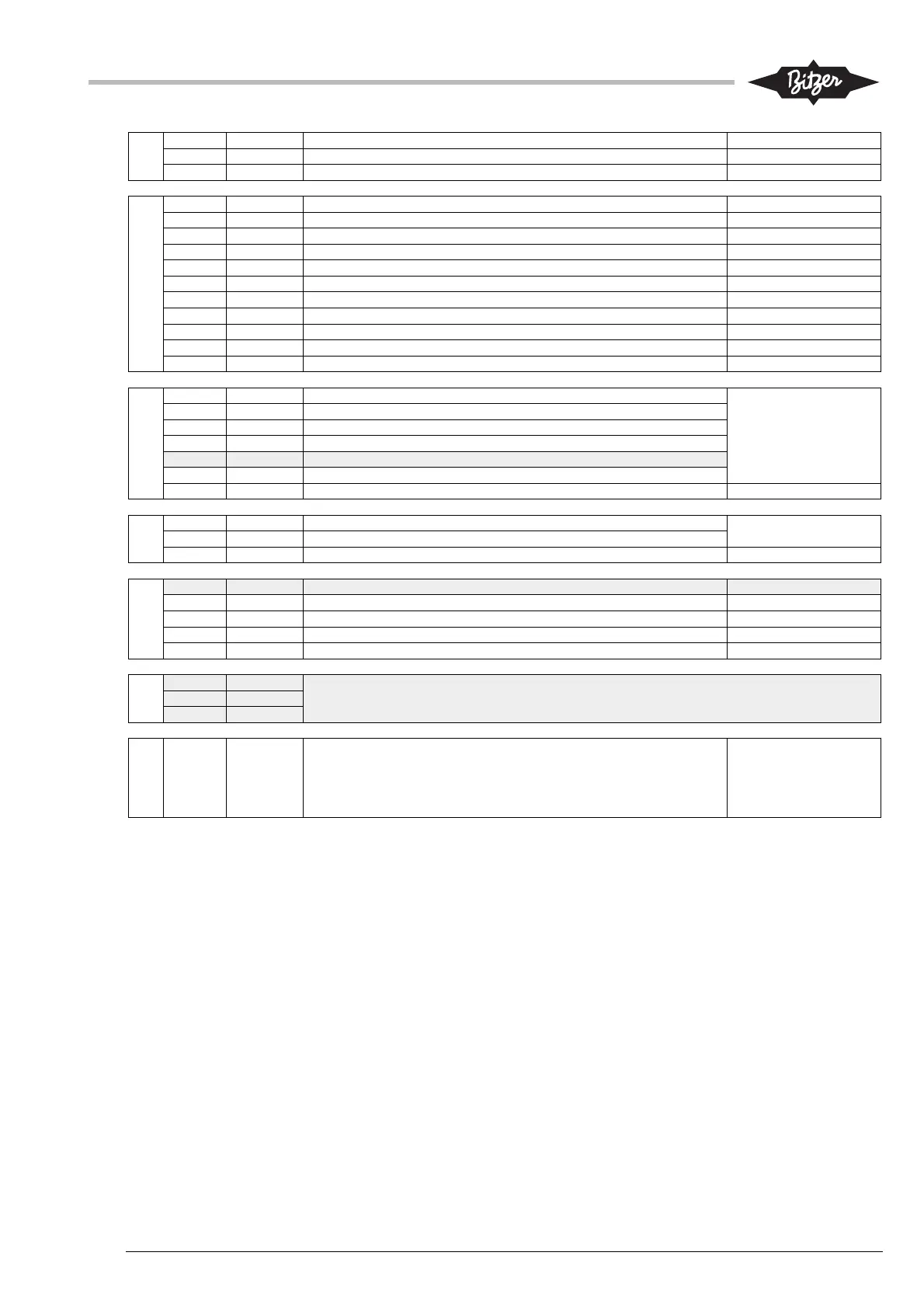

CN6

C8 Relay Common Upto250V,1A

DO8‐ Relay Startsignalforoilpump(optionalcontactNC)

DO8 Relay Startsignalmotoroilpump(standardcontactNO)

CN5

AI1 + Motorcurrent1 0‐10Vdefault

AI2 + Motorcurrent2 0‐10Vdefault

AI3 + Motorcurrent3 0‐10Vdefault

AI4 + Remotesetpoint2 0‐10Vdefault

AI5 + Externalsuctiontemperature PT1000default

AI6 + Externaldischargetemperature PT1000default

AI7 + Externalsuctionpressure 4‐20mAdefault

AI8 + Commondischargepressure 4‐20mAdefault

GND Connectedtoallvoltagesensorsand3‐wirecurrentsensors

5Vdc Usefor0‐5Vrat.

24Vdc Useforcurrentsensors

CN4

DI8 + PIDsetpoint2enable

Supplyfrom24VDC+

2AFuse

(Customerfuse)

DI7 + Remoteeconomizerenable

DI6 + Oilpumperrorsignal

DI5 + Oilpumprunsignal

DI4 + Currentlimiter(notused)

DI3 + Externalstartpermission

COM_DI 24VDC‐ Common–

CN3

DI2 + Externalalarm(inputfromcustomer)

Supplyfrom24VDC+over

2AFuse(Customerfuse)

DI1 + Emergencystop(inputfromcustomersafetychain)

COM_DI 24VDC‐ Common–

CN2

AO4 Notused(spare)

AO3 + SpeedsetpointHzforVSDComp.3 0‐10Vdefault

AO2 + SpeedsetpointHzforVSDComp.2 0‐10Vdefault

AO1 + SpeedsetpointHzforVSDComp.1 0‐10Vdefault

GND Com

CN1

GND RS485‐2GS

Notused‐ RS485‐2‐

+ RS485‐2+

Row

Ternimal

Connection

Description

Instruction

Voltage

Fuseinfo

(where

available)

Terminal plan electrical panel I/O module (M172)

7.3 Compressor modules (CM-SW), additional motor boxes, oil separator module (CM-IO)

The connections to the compressor modules, the additional motor boxes and the oil separator module are all

pre-wired and connected from the factory.

7.4 Economizer system module (CM-IO)

When using an economizer, it must be connected according to the terminal plan in section 7.1. The customer

must connect (cables supplied by customer) the economizer system module with the ACP LINK panel:

Supply 230/115 VAC, connect to CN1

Supply 24 VDC, connect to X54:DC- and X54:DC+

Modbus RTU, connect to CN14

Loading...

Loading...