CT-600-2 51

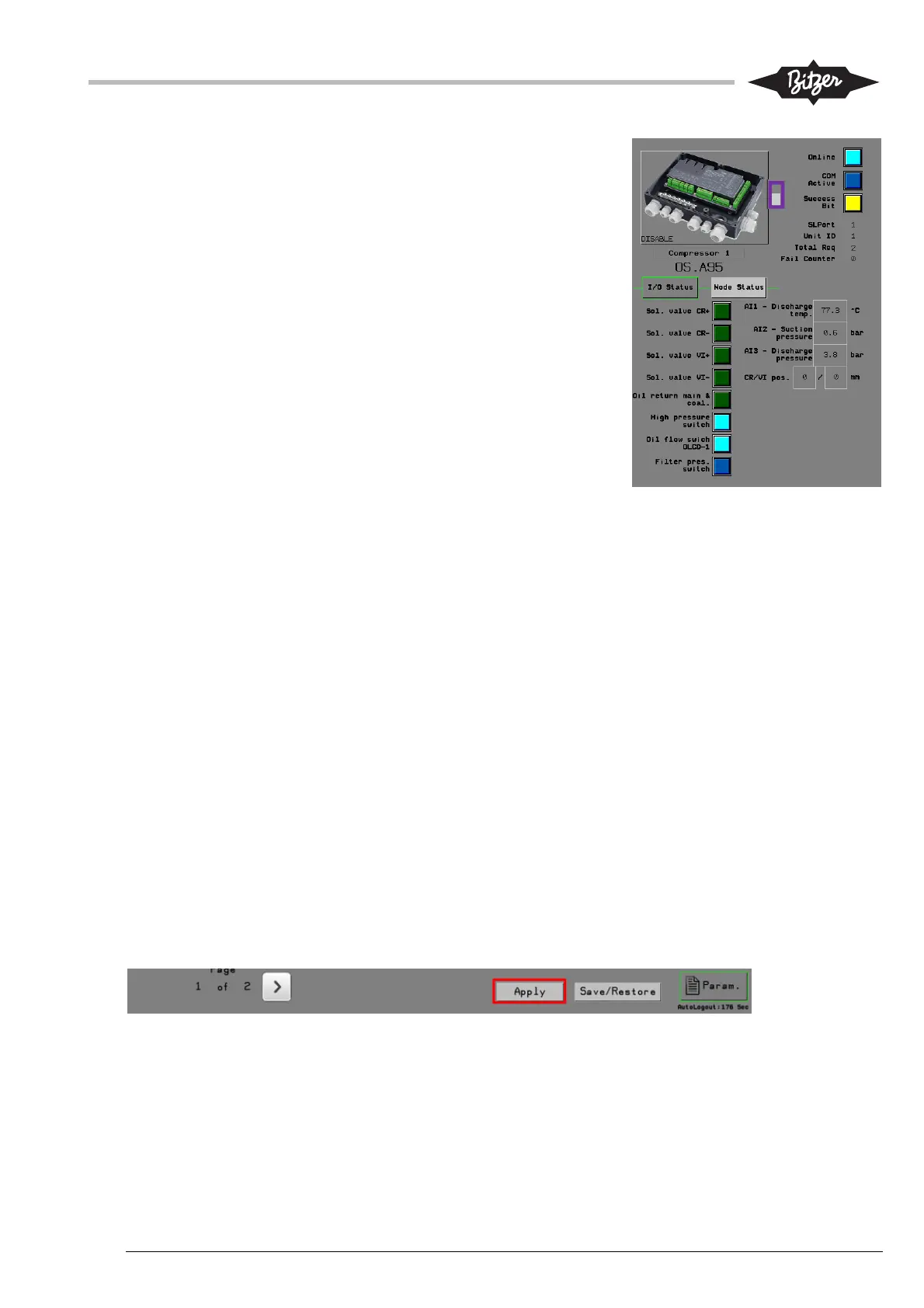

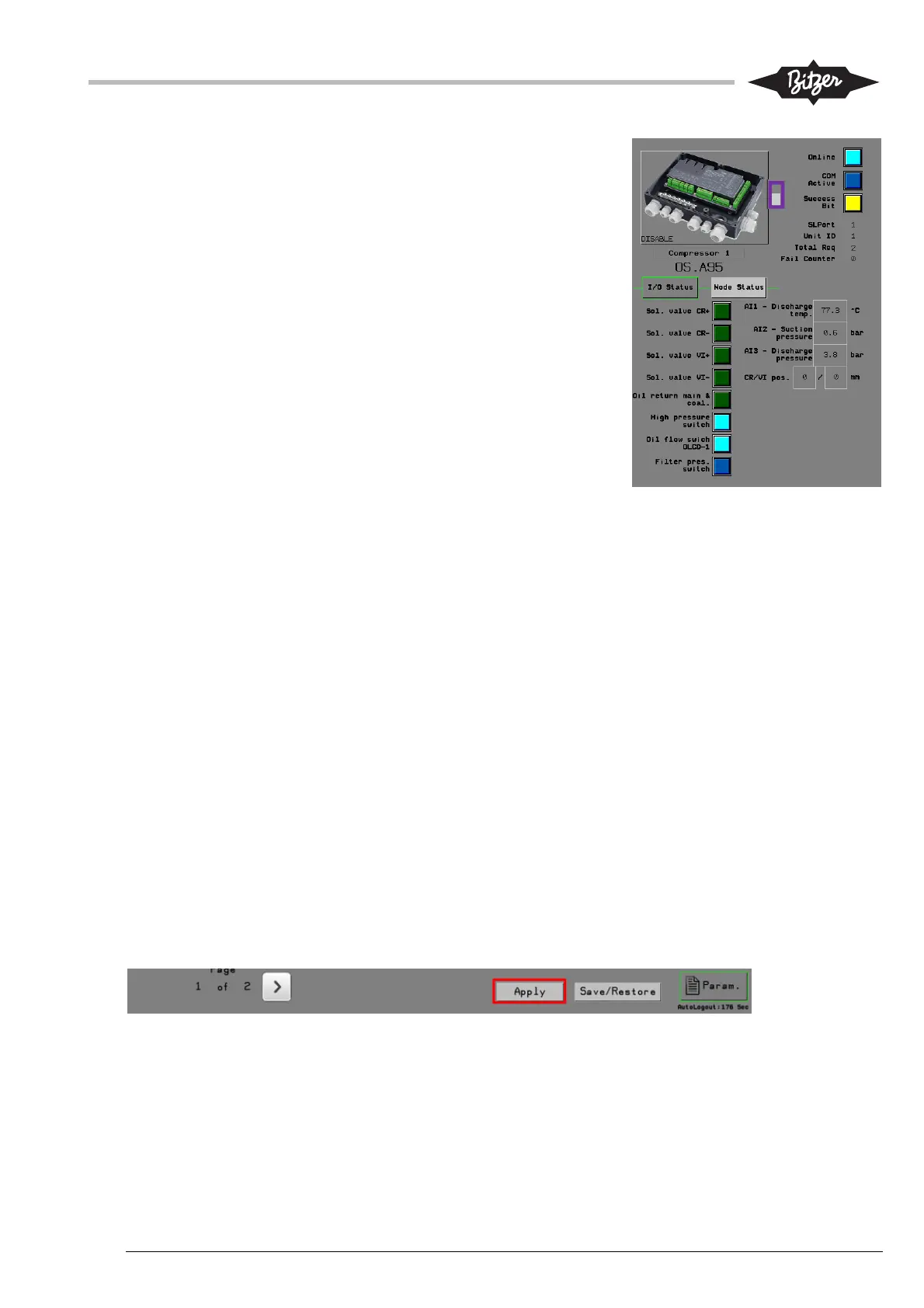

Compressor modules (C1, C2, C3)

The compressor modules (CM-SW-01) communicate with the ACP

LINK PLC over Modbus RTU. The node addresses are configured

with BEST software on the module (see 9.4). The network

communication between the PLC and the compressor module

must be enabled by pressing on the button with picture of the

module in the right side of the screen [1]. The lamps and

information next to the button show the communication status. The

lamp “online” must light continuously to indicate proper

communication. For the communication to be successful, it is

necessary to have the configuration and parameters for PLC and

modules set up correctly. See sections 9.2 and 9.4 on how to

configure.

The right side of the page also shows two tabs with values of the

inputs and outputs and status for relevant parameters on the

compressor.

Electrical panel IO-module (IOSP)

The electrical panel IO-module also communicates with the ACP LINK PLC over Modbus RTU and connects

the digital and analog input and output signals from the plant to the ACP. The node address must be set

correctly on the M172 module, see section 9.6. The communication to the module must be enabled by

pressing the button with picture of the module in the right side of the screen, similarly as for the compressor

modules.

The user can monitor the status of the different inputs and outputs to/from the module with the three tabs on

the right side of the page.

Oil and economizer system modules (OAHC & ECOSYS)

The CM-IO module on the oil separator and the optional economizer function as a remote IO modules and

communicate to the ACP LINK PLC over Modbus RTU. Setup and connection is similar as described above

for the compressor modules.

10.11 Parameters and timers screen (Param.)

The screen to view and change parameter and timer settings is accessed at the right-hand bottom corner of

the HMI. The top of the Parameter screen shows buttons that link to different sub sections. Each sub section

can consist of multiple pages that can be access using the arrow buttons in the bottom of the page.

See section 9.2, 9.3 and 0 for further information on the different parameters. Section 11 describes the

different functions in the ACP LINK PLC including the parameters and timers used for each function.

When logged in as “Service” it is important to note, that after any change has been made to a parameter or a

timer, the “Apply” button at the bottom of the screen must be pressed for the change to take effect. If the user

switches to a different screen without pressing “Apply”, the settings are discarded.

1

Loading...

Loading...