36 CT-600-2

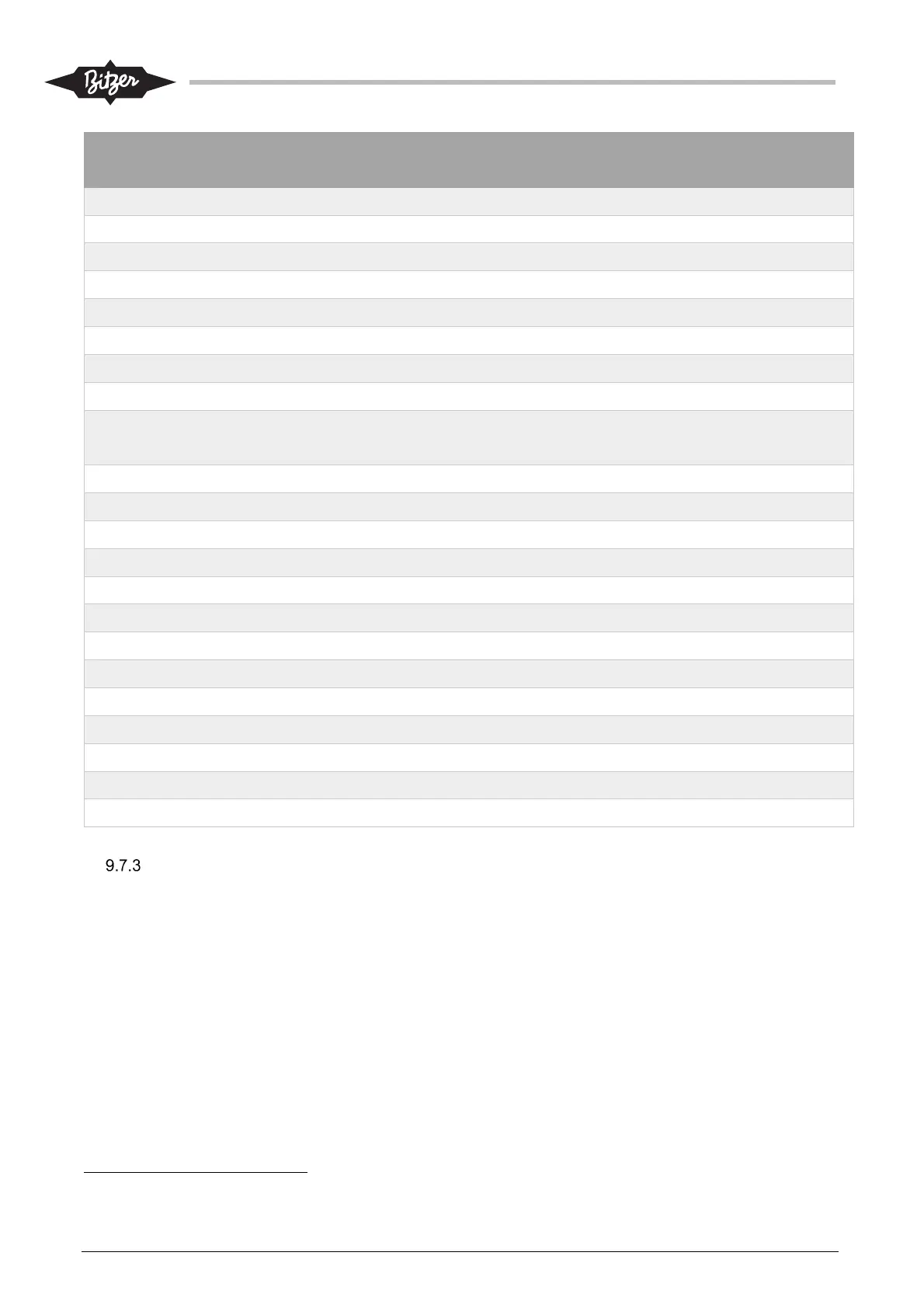

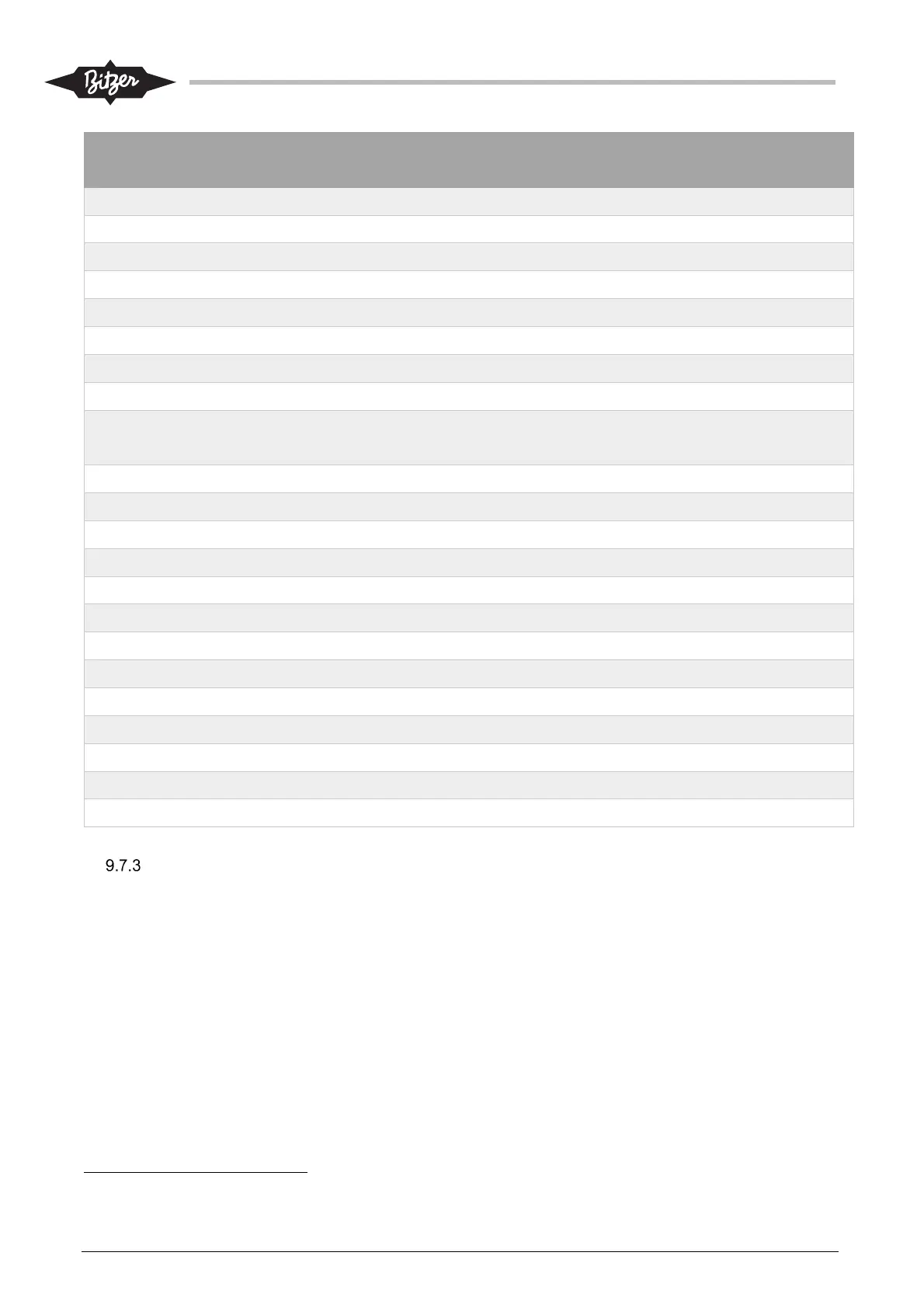

Parameter WEG Par.

No.

Value Note

LOC/REM Selection Src 220 1: Always REM

LOC JOG Selection 225 0: Disable

REM JOG Selection 228 0: Disable

Stop mode selection 229 1: Coast to Stop

Dead Zone (AIs) 230 1: On

AI1 Signal Function 231 0: Speed Ref.

AI1 Signal Type 233 0: 0 – 10V

AO1 Function 251 5: Output Current

AO1 Signal Type 253 0: 0 – 10V /

4-20mA

Optional “1: 4 – 20mA”, requires adjustment

of VSD dip-switches, acc. to WEG manual

DI1 Function 263 1: Run/Stop

DI2 Function 264 0: Not Used

DI5 Function 267 0: Not Used

DI6 Function 268 0: Not Used

DO1 Function (RL 1) 275 11: Run Feedback for CM-SW-01 Comp. module

DO2 Function (RL 2) 276 26: Fault Alternative: “13: No Fault” (not fail-safe!)

Application 298 1: Heavy Duty

Fan Control Config: 352 4: HS-CT, Int-ON

Motor Rated Voltage 400 Motor specific Acc. motor nameplate/datasheet – See note

5

Nominal Current 401 Motor specific Acc. motor nameplate/datasheet – See note

2

Nominal Rated Speed 402 Motor specific Acc. motor nameplate/datasheet – See note

5

Motor Rated Frequency 403 Motor specific Acc. motor nameplate/datasheet – See note

5

Motor Rated Power 404 Motor specific Acc. motor nameplate/datasheet – See note

5

Speed set point settings in ACP LINK

The speed set point is send to the variable speed drive as an analog 0-10 V signal, coming from the electrical

panel IO-module. The speed set point in the ACP LINK PLC (output from M251 PLC to M172) is calculated in

the range 0 – 1000, which corresponds to 0 – 10V output from the M172 electrical panel IO-module. The

calibration of output is done on the ACP LINK HMI and must correspond to the calibration of the analog input

on the variable speed drive (see also section 9.2).

The formula used to calculate the output signal, based on the set point for the frequency is:

Output [0..1000] = frequency_setpoint [Hz] * A + B. Output “1000” equals 10V.

Standard recommended parameters are shown in table below:

2

NOTICE: WEG 300V-70Hz motors: adjust to values for 70Hz / 400V! – Do not use data for 300V!

Loading...

Loading...