CT-600-2 43

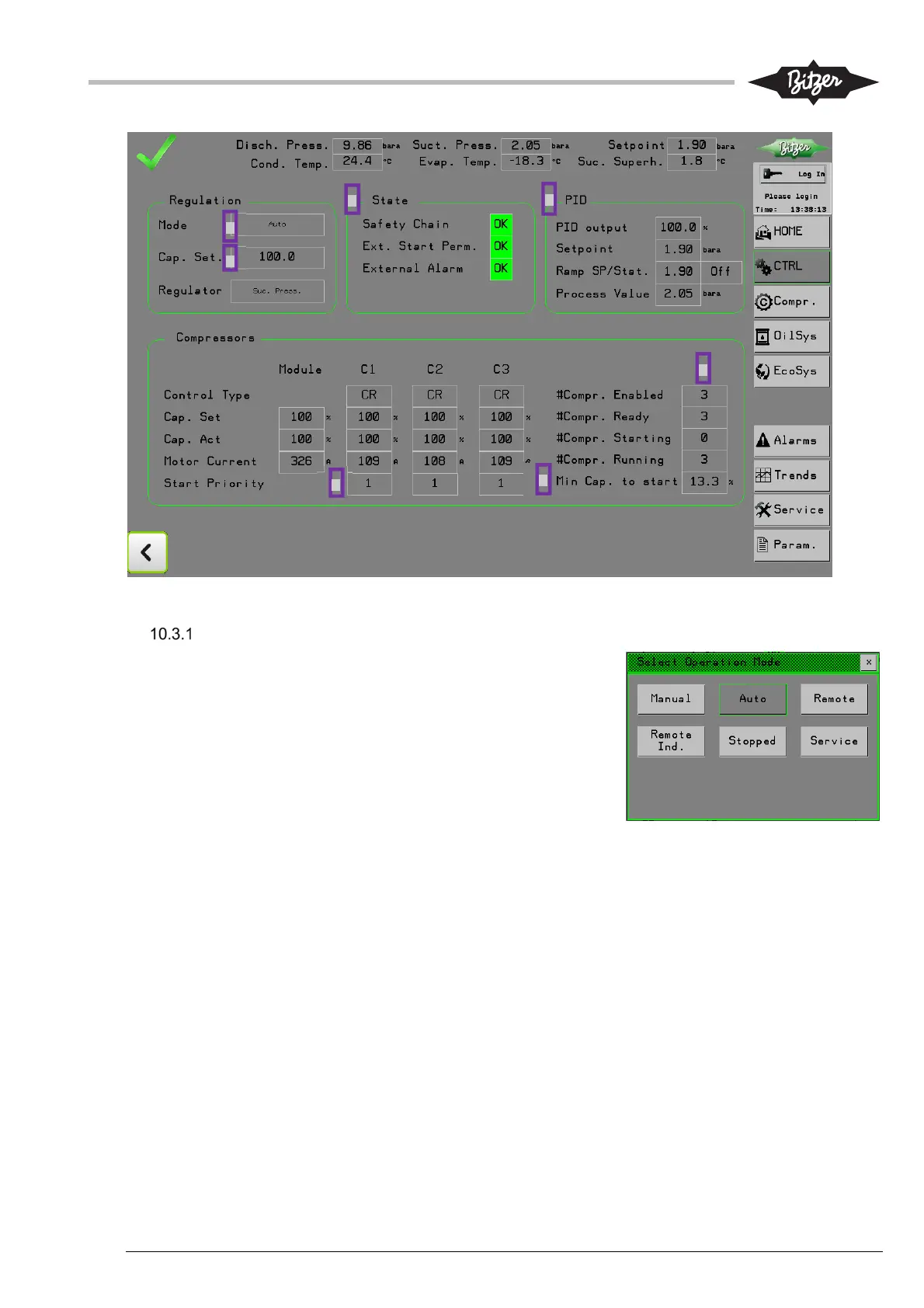

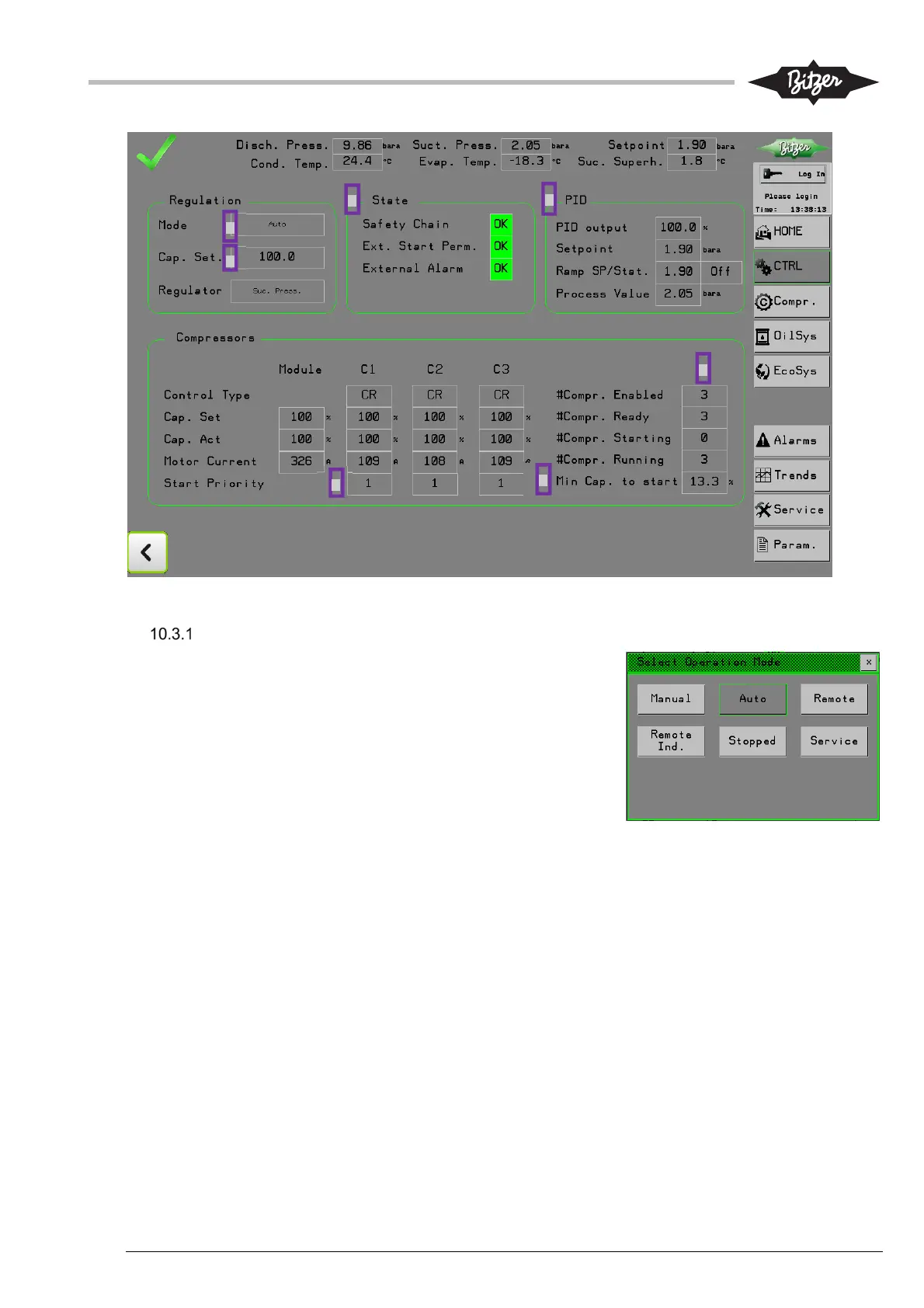

Regulation / Select Operation Mode

The ACP can operate in different modes. The ACP LINK will distribute

the requested capacity over the available compressors in all modes,

except for “remote ind.” and “service”, where the capacity of each

compressor is handled separately. The distribution of the capacity

over the compressors is done in a way to assure a certain

compromise between energy efficiency and control accuracy. See

also item no. 3.5 in section 12.4 about capacity distribution between

compressors. Take in mind that the first compressor to start will

require that the requested capacity is 1/3 above the minimum nominal

capacity of the ACP. The minimum capacity to start is displayed on

the CTRL screen [7]. The last compressor will only stop when the requested capacity is below 1/3 of the

minimum capacity of the ACP

Definition of minimum nominal capacities and minimum capacity to start

The minimum nominal capacity levels of the compressors and the unit are used to decide whether to start or

stop the operation of the unit or the single compressor in the operating modes manual, auto, remote and

remote individual.

Minimum nominal compressor capacity for a slide valve regulated compressor is defined as the minimum slide

valve position.

Minimum nominal compressor capacity for a speed regulated compressor is defined as the ratio between the

minimum and the maximum speed..

The minimum capacity of the unit is equal to the sum of the minimum capacity for each compressor, which in

case of variable speed operation is corrected with the ratio between the maximum frequency and the line

frequency.

The minimum capacity to start (operation modes manual, auto and remote) is exactly 4/3 times the minimum

nominal capacity of the unit. The minimum capacity to start is higher than the minimum nominal capacity in

order to assure that the ACP LINK can regulate the capacity (up/down), once started. It also assures that a

2

3

4

5

6

1

7

Loading...

Loading...