Group 03, Section 01, Page 6 Mechanical Dock Leveler – M and FMC

Issue Date: 10/01/01, Rev, 0 (Part #038-550E)

DETAIL OF COMPONENT FUNCTIONS – cont’d

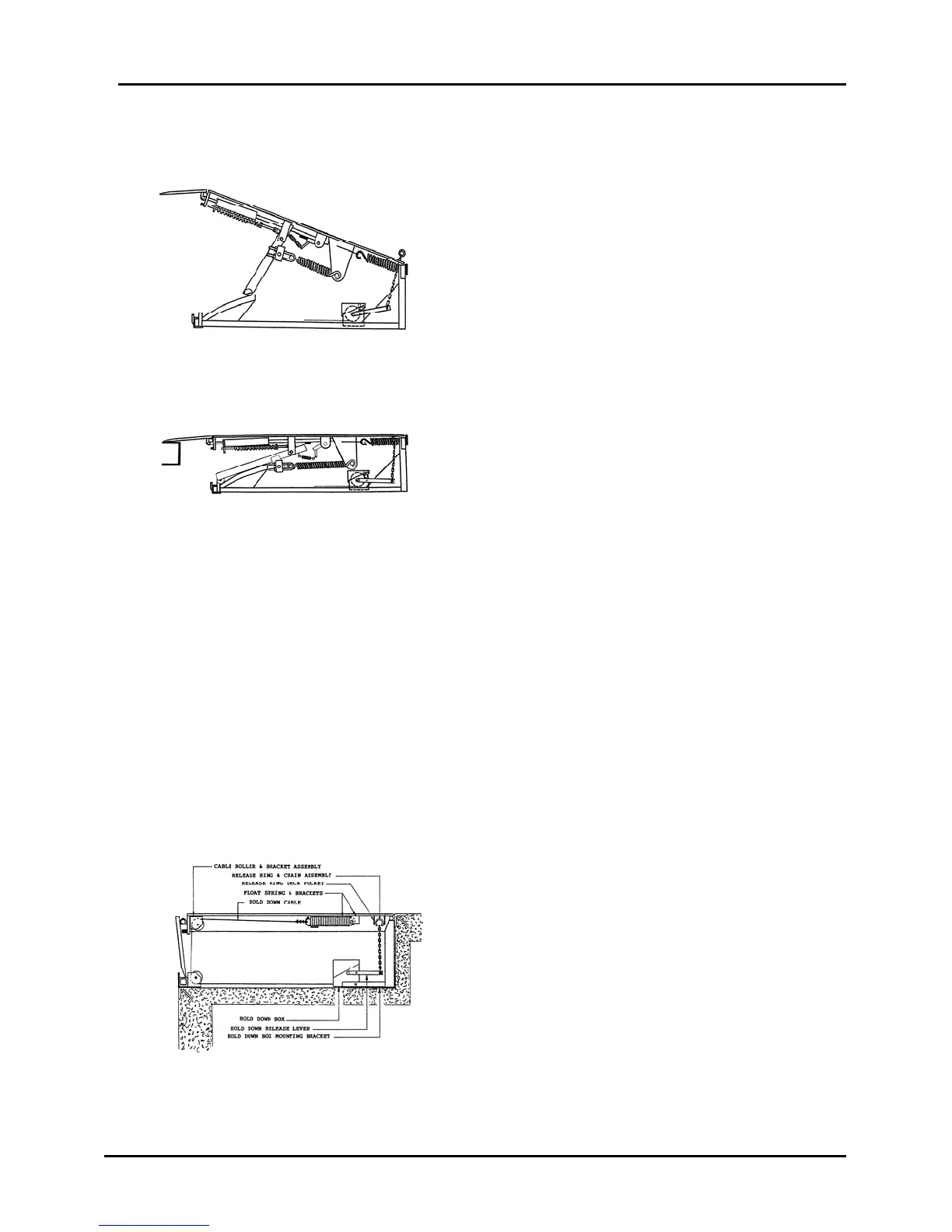

In this view the deck has been allowed to

raise to the point where the actuator

extended the lip. Notice that as the

actuator assembly moved forward – the lip

lock was pulled into its locking position.

The spring will maintain tension on the lip

lock while the deck is in the raised

position. When the deck is walked down

by the weight of the operator – the weight

of the lip will be supported by the lip lock.

After the loading / unloading process is complete – the operator pulls the release

chain to release the hold down device. The operator can now allow the dock deck to

raise high enough to allow the lip (now unlocked) to drop into its hanging position.

The lip is now ready and in position to enter the lip keepers when the operator walks

it down.

The lip and the lip keepers will now support the outer weight of the deck assembly in

the stored position.

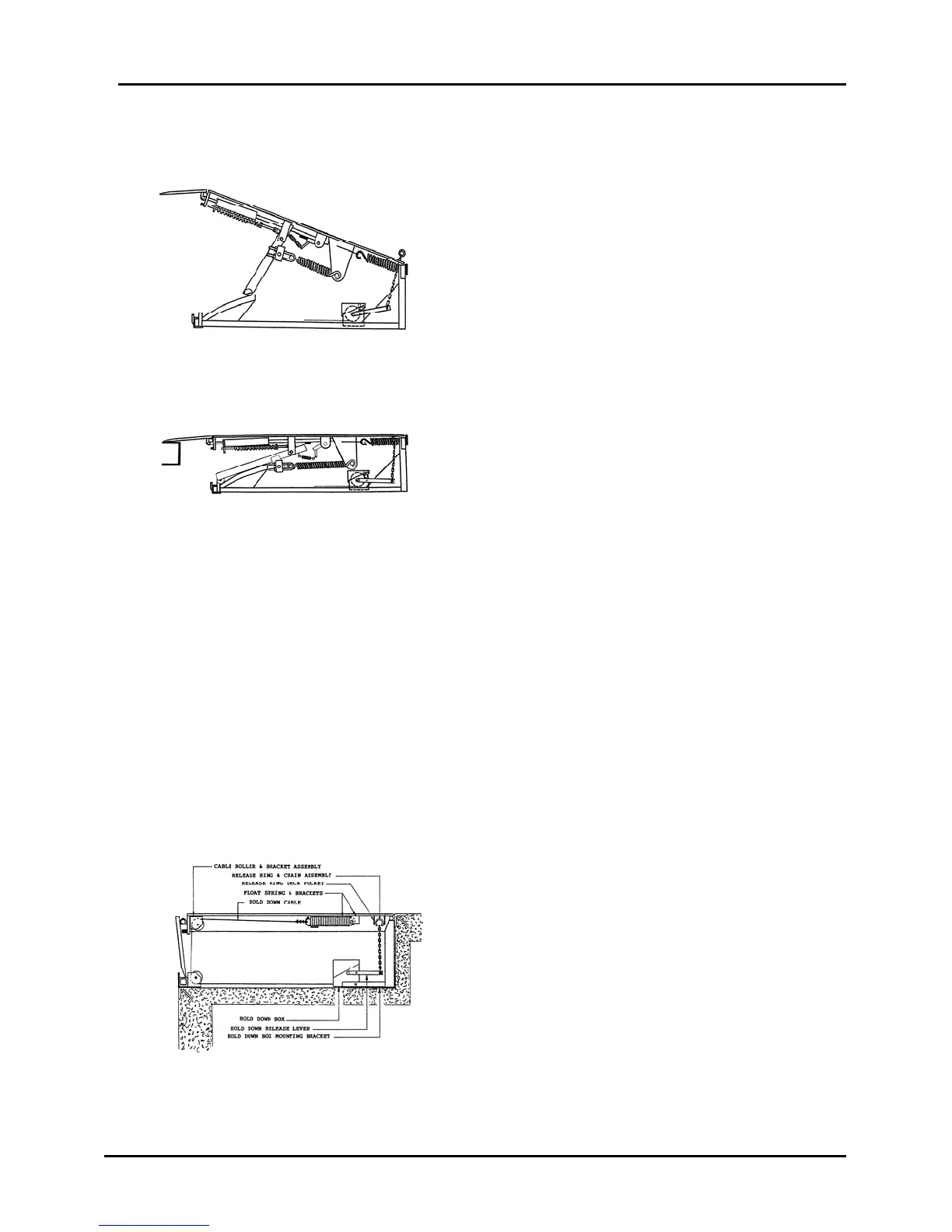

We have previously referred to the

opposing force or braking action of the

hold down box and cable, on the biased lift

springs. In this picture we can follow the

cable routing. The cable is attached

through a float spring to the rear solid

portion of the dock leveler deck. It is

routed forward to a pulley that is mounted

at the front of the deck. It then proceeds

downward through another pulley that is

mounted on the lower front beam of the

stationary frame. The cable then extends

rearward where it enters the hold down

box where tension is applied by a rewind

spring.

This view shows the deck lowered and the

weight of the deck now being supported by

the truck floor.

At this time the actuator and the lip lock

have done their job. Because the weight of

the lip has been taken by the truck floor –

the weight of the lip is no longer exerting

force on the lip lock. The fact that the Lift

Arm is now in a lower position – the spring

is relaxed – gravity takes over and allows

the lip lock to drop out of locked position.

Loading...

Loading...