Mechanical Dock Leveler – M and FMC Group 03, Section 01, Page 7

Issue Date: 10/01/01, Rev. 0 (Part #038-550E)

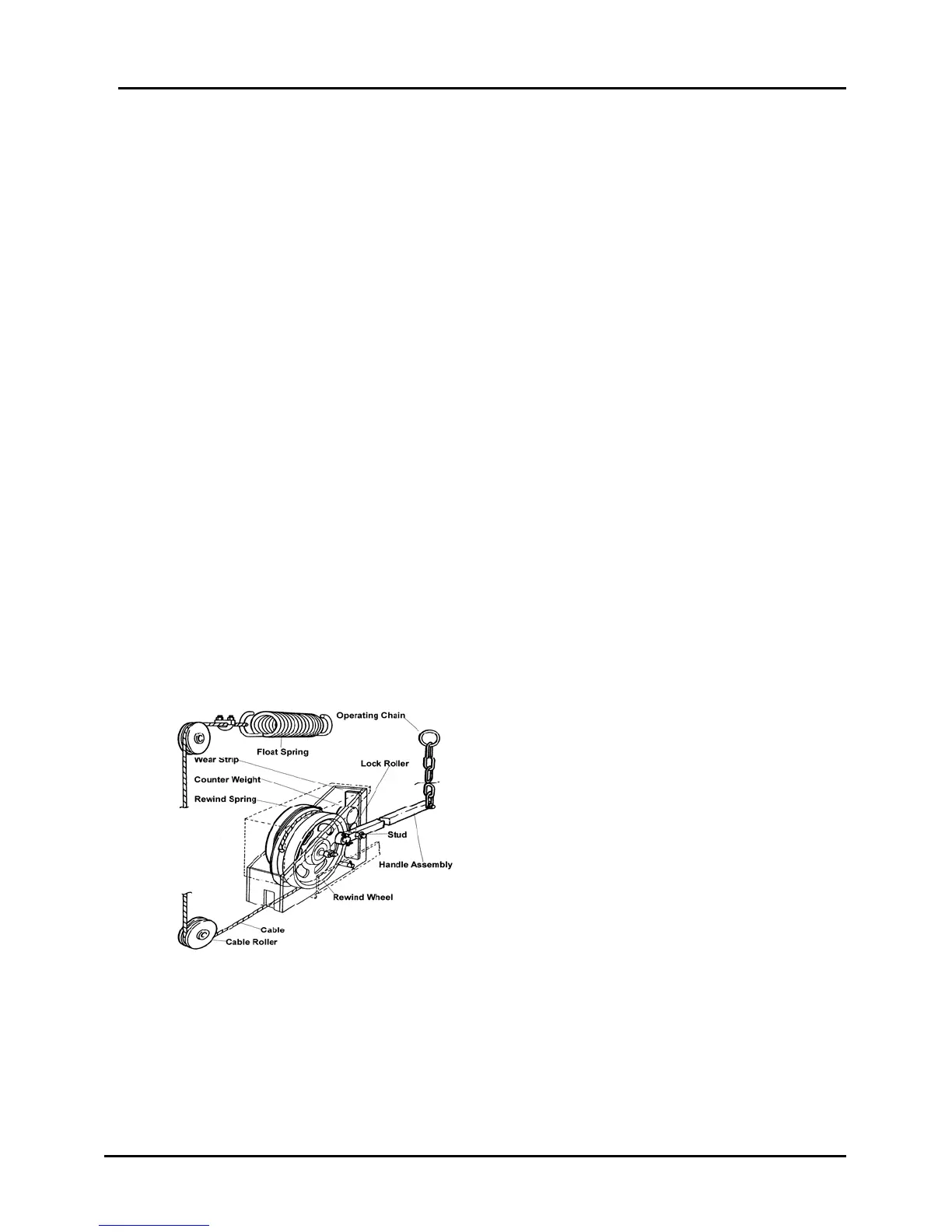

DETAIL OF COMPONENT FUNCTIONS – cont’d

In this picture you can see the

working components of the hold

down system.

They are:

–Handle Assembly

– Rewind Wheel

– Coil Spring

– Wear Strip

– Counter Weight

– Knurled Lock Roller

– Cable, etc.

The hold down mechanism is

designed to work as a one-way

direction check for the cable.

As you can see here, the rewind spring is always trying to pull the cable

towards the hold down box. The rewind spring only has enough power

to rewind the cable as the deck moves downward.

The cable can always move toward the box when the deck is moving

downward however, because of the braking action applied to the cable

by the hold down box, the cable can not move outward until the brake is

released by pulling the operating chain.

This devices makes sure that the dock leveler always maintains a

positive downward force – through the lip when it is engaged with the

truck floor.

Since the brake creates a positive downward action to keep the lip

engaged with the truck floor, it is necessary to provide for and allow

movement of the deck and lip in an upward direction. This would occur

as a truck is being unloaded. As the load on the truck lightens, the

suspension tends to raise the truck bed.

As you can see here – this non-positive cushioned action is provided

through the cable by the float spring.

Loading...

Loading...