Mechanical Dock Leveler – M and FMC Group 08, Section 17, Page 3

Issue Date: 10/01/01, Rev. 0 (Part #038-550E)

LONGER LIP REQUIREMENT – cont’d

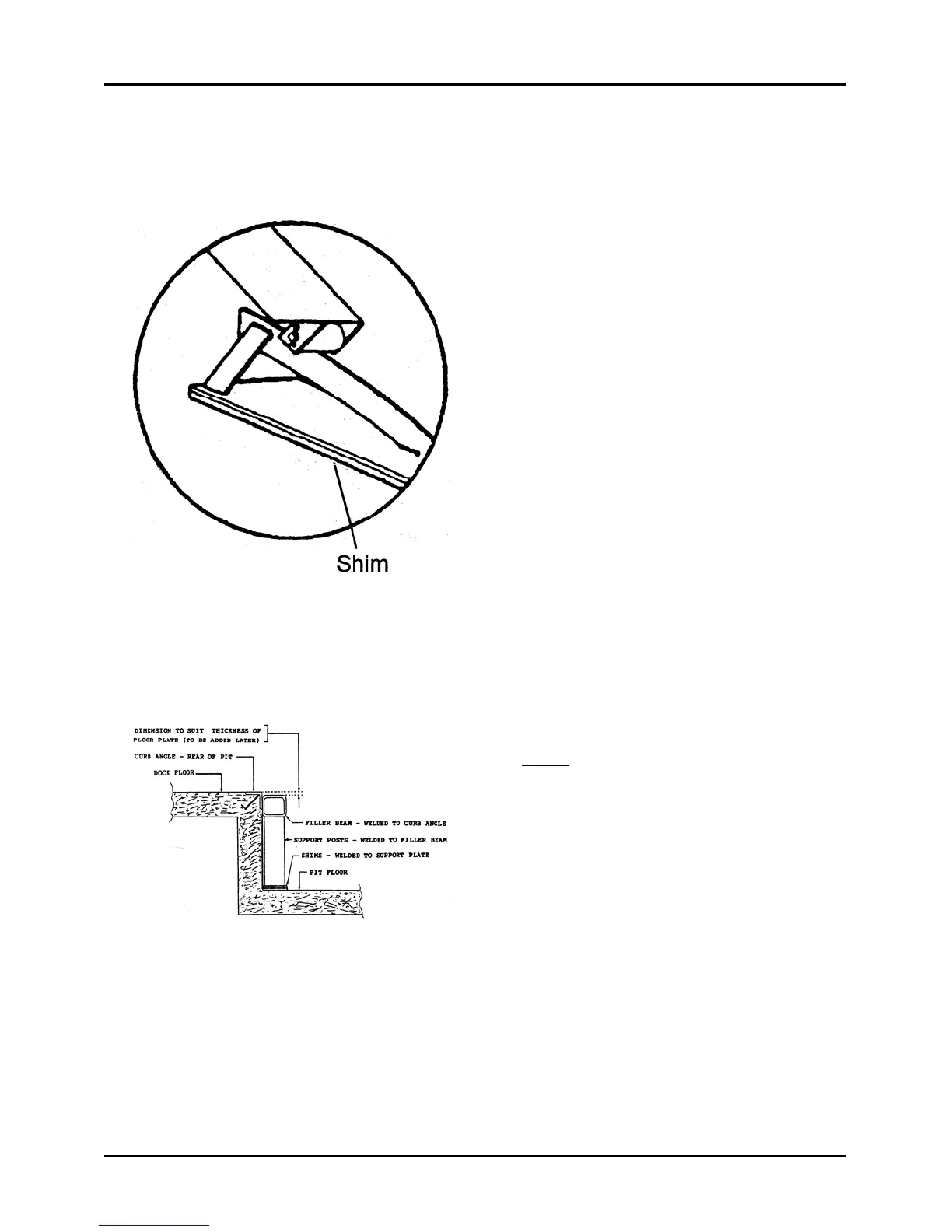

Move Dock Leveler Forward

Inspect the lifting arm cam mounting

plate to determine if shims are located

between it and the pit floor. If shims are

present, move forward with the unit. See

Figure 96. Plate must be level front to

back.

Remove both dock bumpers.

When all retaining welds have been

removed and unit is free to be moved

forward, remove the safety stand and

lower the maintenance strut. Walk the

deck down to its stored position and

tack-weld a retaining strap between the

lip and the front frame or tack weld the lip

to the frame to assure the deck does not

raise as the dock leveler is being moved.

Using appropriate equipment and/or

tools, move the entire unit approximately

16" forward in the pit to allow working

space at the rear of the pit.

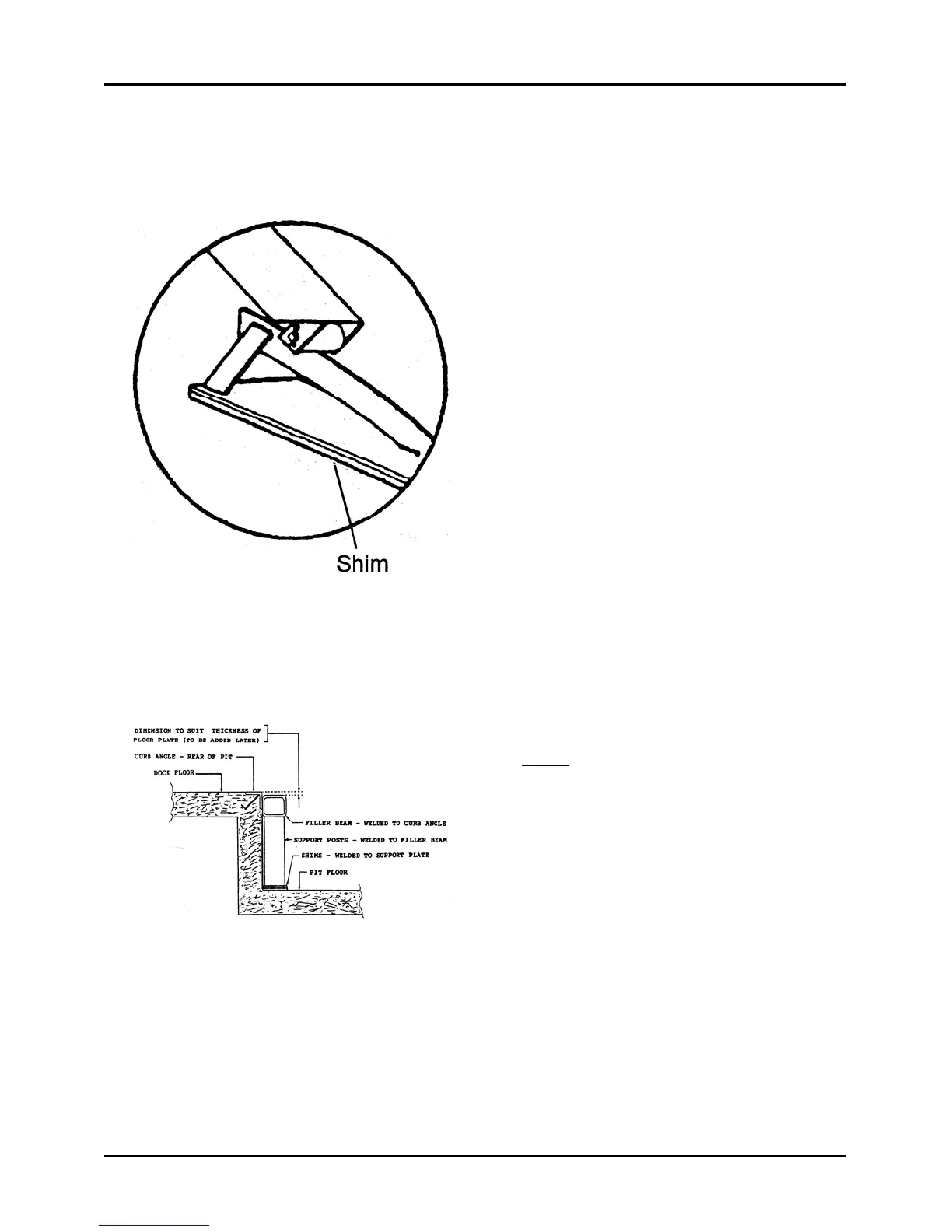

See Figure 97 for illustration of typical

rear filler beam, vertical supports and

shims.

Note: Vertical support posts must be

located under the filler beam in a quantity

that equals the quantity of vertical

supports in the dock leveler frame, with 3

supports being the minimum quantity

used. One at each outer end and one in

the centre.

Weld shims under the vertical posts if

required, to assure positive contact with

the pit floor for maximum support.

To eliminate any possibility of wide floor

cracks after completion, the rear filler

beam will be located 1/4" lower than the

dock floor and then be covered with a

1/4" thick floor plate to completely fill the

space between the curb angle and the

dock leveler back beam.

Figure 96

Figure 97

Loading...

Loading...