Probus DP V1 Agile 3906/2010

The displayed "PDP active current" depends on the control system. In field-

forming current is displayed, in applications with a v/f characteristic control,

the active current, which is also a measure for the torque.

The “PDP absolute current” (r.m.s. current) is always positive. Active current and torque-

forming current have a sign prefixed.

Positive currents = motor

Negative currents = generator operation.

Reference value Binary Decimal Hexadecimal

+ 100% + 2

The possible range = ±200% = +32768 to -32768 = 0x8000 to 0x7FFF

For the internal scaling, the data set change-over capable parameter

Rated current 371 is used as a

reference.

371 Rated Current 0,01 · I

Handling of the Objects

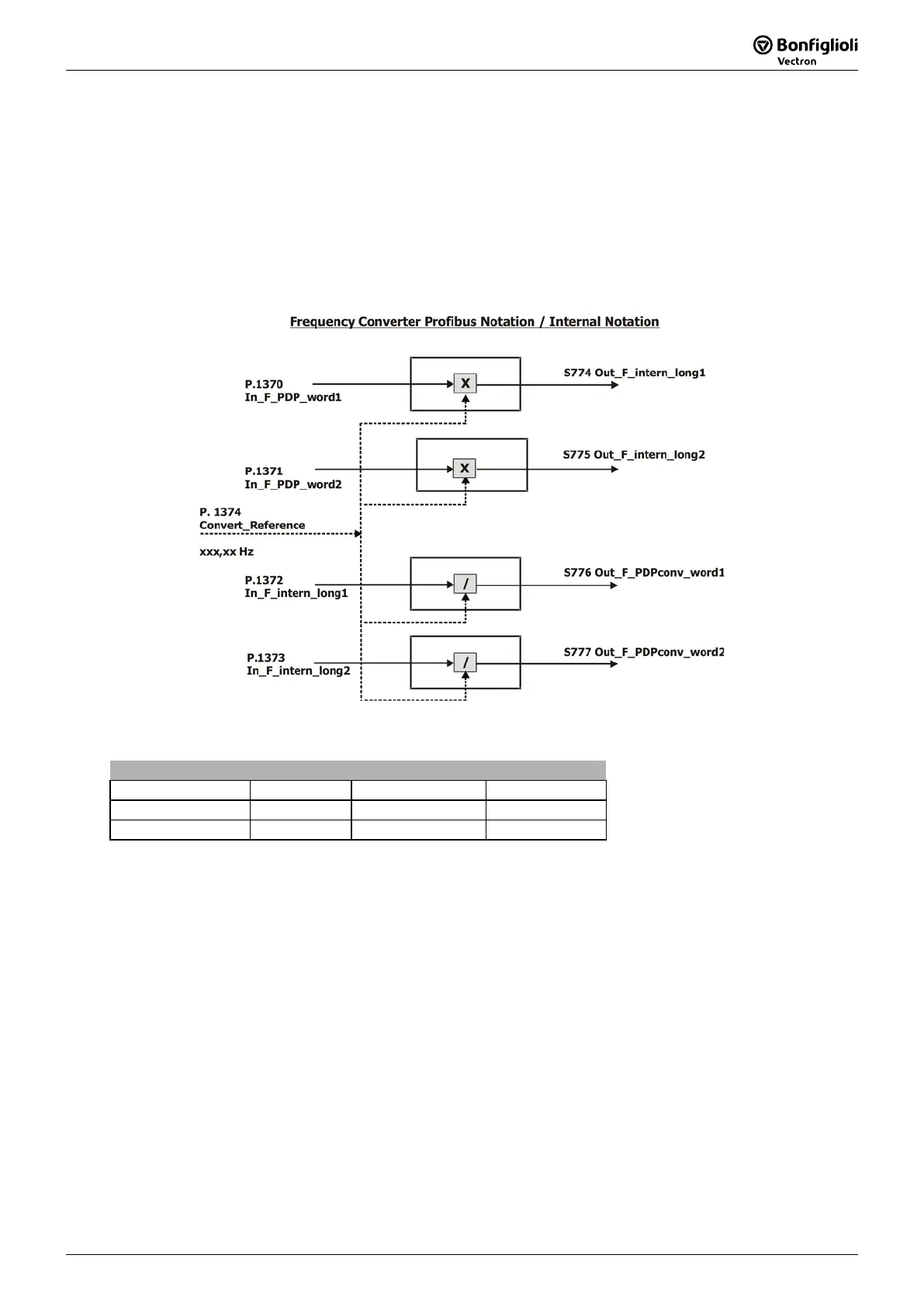

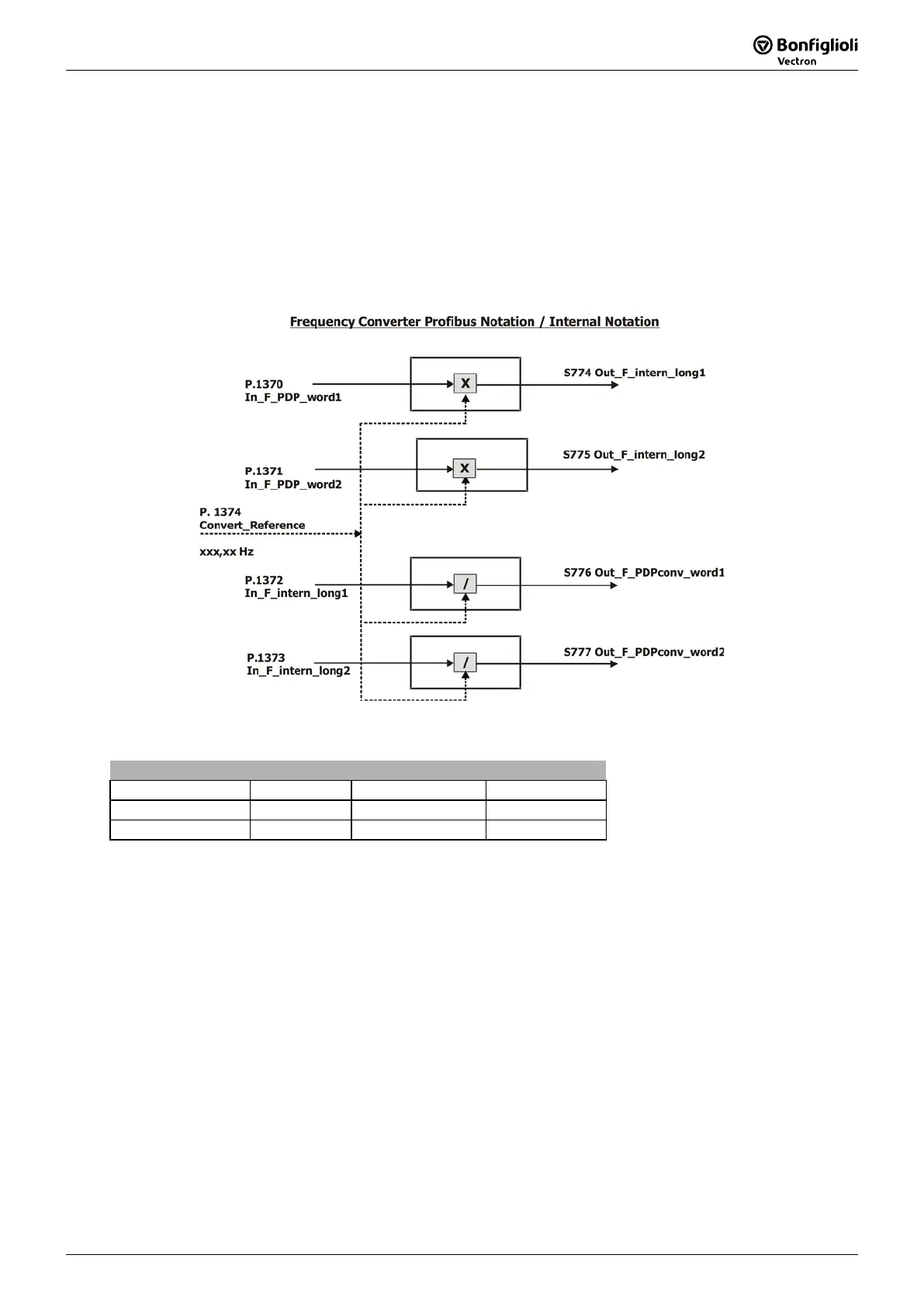

16.4 Frequency Conversion PDP Word to/from Inverter Internal Notation

1370 In-F-PDP-word 1

1371 In-F-PDP-word 2

1372 In-F-intern-long 1

1373 In-F-intern-long 2

1374 In-F-Convert Reference

The function

Convert PDP/intern

converts frequency values in Profibus

notation to frequency values in

device-internal notation and vice versa. See Chapter 16.4.5 "PZD2, Reference Value / Actual Value".

The scaling for In_F_PDP_word1/2 and Out_F_PDPconv_word1/2 is:

Standardization

Reference Value Binary Decimal Hexadecimal

+ 100% + 2

16384 0x4000

- 100% - 2

49152 0xC000

The possible range = ±200% = +32768 to -32768 = 0x7FFF to 0x8000

This function uses its own reference value

Convert-Reference

1374 for data conver

of this function is the usage of the word data type for frequency values, instead of long.

Note: The usage of this function and the usage of In-PZD/Out-

PZD objects is shown in the

sample project documented with:

− CM_PDPV1_conf.pdf Cluster with one inverter and CM-PDPV1 and three additional

inverters coupled by Systembus

− CM_PDPV1_S7.pdf Functional description

− CC_0B2C.zip Complete STEP7 project including samples for In/Out-PZD usage

and parameter access via PKW object and V1 channel

− S7-SoftwareOB1.pdf Listing of OB1 from STEP7 project

Loading...

Loading...