Probus DP V1 Agile 5306/2010

State HEX (*) Bit 6 Bit 5 Bit 3 Bit 2 Bit 1 Bit 0

Switch On 0x23 0 1 0 0 1 1

Operation enabled 0x27 0 1 0 1 1 1

(*) without considering bits 7 to bit 15

The occurrence of a fault leads to a switch-over to the "Fault" state.

A fault can only be acknowledged 15 seconds after its occurrence, as a blocking time is

active internally.

Bit 7 "Warning" can be set at any time. It indicates a device-

internal warning message. The

evaluation of the present warning is carried out by reading out the warning status with parameter

Warnings

is set if the operation mode control via remote contacts (

the hardware release is available. Only then can the frequency inverter be

controlled via the control word.

Bit 10 "Reference value reached" is set whenever the specified reference value has be

en reached.

In the special case of power failure regulation, the bit is also set if the power failure regulation has

reached the frequency 0 Hz (see operating instructions). For "Reference value reached“ there is a

hysteresis (tolerance range), which can be set via parameter Reference Value Reached: Hysteresis

549 (see operating instructions).

Bit 11

"Limit value active" indicates that an internal limit is active. This can, for example, be the

present current limit, the torque limit or the over-voltage l

imit. All the functions lead to the reference

value being quit or not reached.

Bit 15 "Warning 2" indicates a warning which leads to a fault switch-off of the frequency inverter

within a short period of time. This bit is set if there is a warning for mo

sink/inside temperature, Ixt monitoring or mains phase failure.

With the use of remote contacts the signal sources* are taken over from the

Word 410. Signals at the hardware contacts (terminals) are not evaluated by t

standard operation modes (e.g. 71 for S2IND).

For the evaluation of terminal signals special operation modes are avail

denoted with the additional term “(Hardware)” and numbered from 526 to 546.

Exception: The controller release via the hardware contacts STOA (termi

STOB (terminal X210B.2) must be set and Bit 0 “Inverter Release” of the Control Word

must be set.

It is not possible to release the controller only via software.

* Signal sources are:

IN1D ... IN5D,

MFI1D, MFI2D

Handling of the Objects

16.4.5 PZD2, Reference Value / Actual Value

In the PZD2, the master gives its reference value to the frequency inverter in the out

information back on its actual value in the input data set.

The use of the reference/actual value ch

annel depends on the configuration setting (control system). The

actual value is generated from one of the sources according to the control system.

390 Profibus Reference

The reference value and actual value are related to the Parameter

375 OR

the Parameter

Profibus Reference

390.

The distinction is made via the setting of parameter

390. If

390

0, Rated frequency 375 is the reference variable. If Profibus Reference 390 ≠ 0, Profibus Reference

is used as the reference variable. Both parameters are capable of data set change-over.

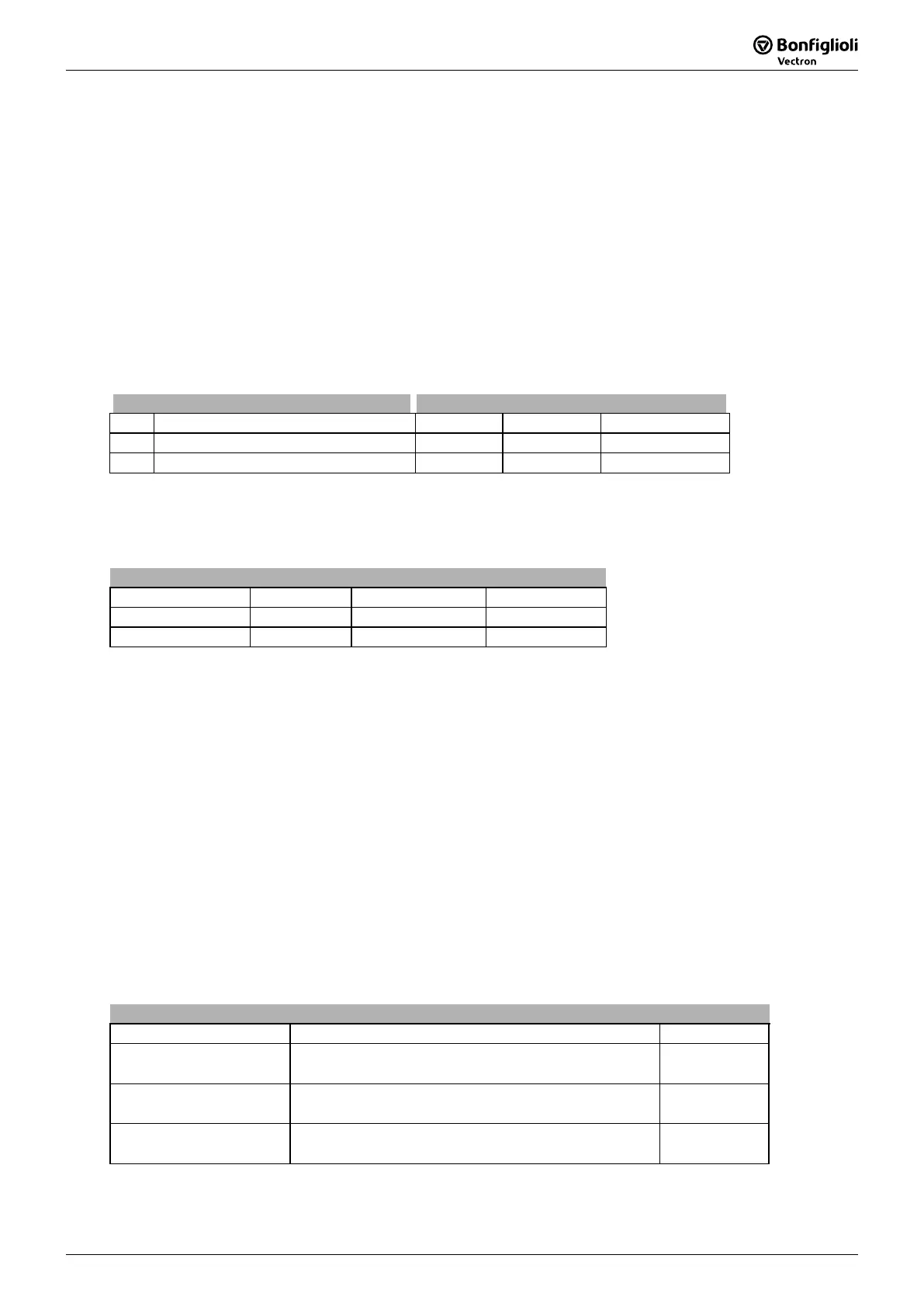

Parameter Setting

No. Description Min. Max. Factory Setting

375 Rated Frequency 10,00 Hz 1000,00 Hz 50,00 Hz

390 Profibus Reference 0,00 Hz 999,99 Hz 0,00 Hz

Reference and actual values are transmitted in a standardized form. The standardiza

by the variables being related to the reference value (Rated frequency 375 OR Profibus reference

390).

Standardization

Reference Value Binary Decimal Hexadecimal

+ 100% + 2

16384 0x4000

- 100% - 2

49152 0xC000

The possible range = ±200 % = +32768 to -32768 = 0x7FFF to 0x8000

Example:

The setting of parameter

390 is the reference value 60.00 Hz.

required reference frequency is 30.00

Hz. This means 50% of the reference value, thus

the set point 8192 (0x2000) has to be transmitted.

With the reference value

390

a machine can also be operated in the field

weakening area above its reference frequency.

Example:

The parameter

375 is set to a frequency of 50.00

parameter

390 to 100.00 Hz the value range of ± 200 Hz is possible.

The reference value for the frequency inverter from PZD2 is provided by the Fieldbus

Value.

In the Reference Frequency Channel, setting "20 – Fi

eldbus Reference Value" can be selected via

Reference Frequency Value Source 1

475 or

Reference Frequency Value Source

492.

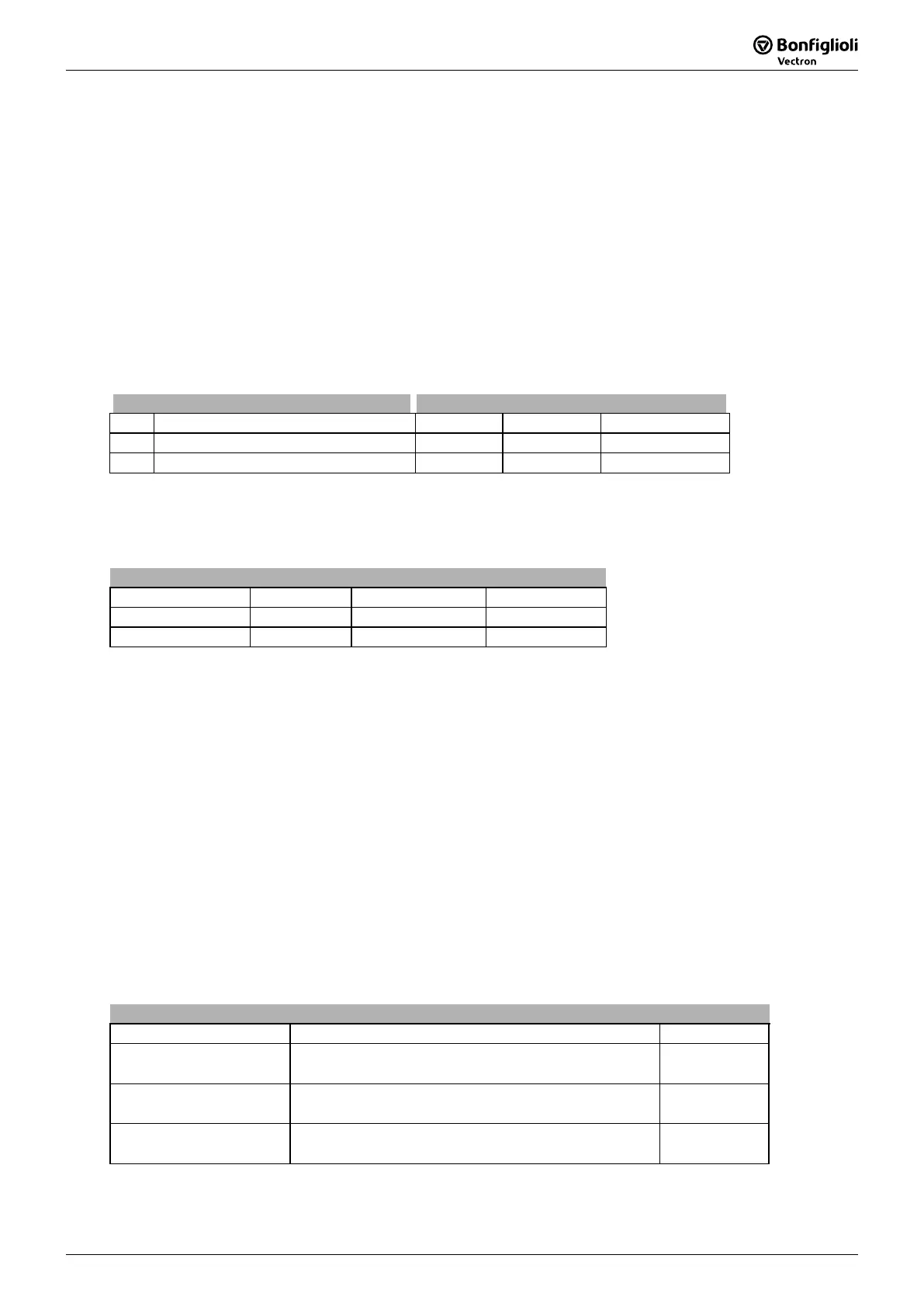

Actual Values

Parameter Content Format

Internal reference

frequency

228

Sum of

Reference Frequency Value Source 1

475

and

Reference Frequency Value Source 2

492.

xxx,xx Hz

282

Fieldbus reference value from Profibus. xxx,xx Hz

283

Actual Ramp Reference Frequency. xxx,xx Hz

Loading...

Loading...