32

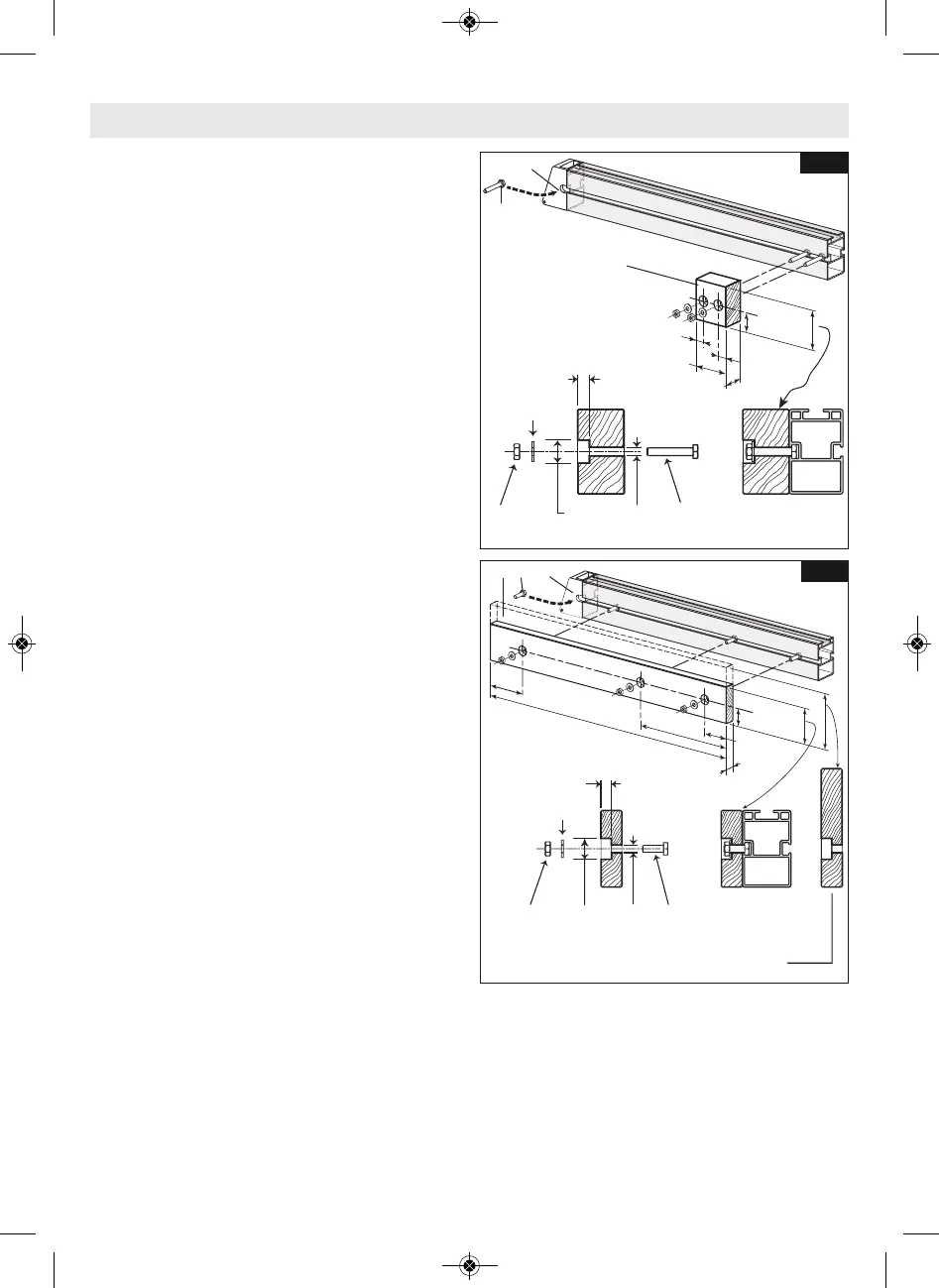

MAKING THE FACING BLOCK

The facing block should be made of 1-1/2

inch (38mm) thick wood – Figure 42 shows

dimensions to make a facing block.

Parts Required:

- 1-1/2” thick wood board cut to size (1)

- 1/4 x 20 x 1-1/2” long hex. head ma-

chine screws (2)

- 1/4” Washers (2)

- 1/4 x 20 machine nuts (2)

The facing block is made to the same height

(2-3/4" [70mm]) as the rip fence and can

work with the blade guard system in place

when cutoff pieces are 1-1/2 inches (38mm)

or greater. Cut the board to the size shown,

drill through 9/32" (7mm) holes, then

counter-sink each hole (down 3/8 inch

[9.5mm]) using a 3/4 inch (19mm) drill bit.

Assembly:

A. Place the hex. head 1 of each machine

screw into the recess 2 in the rear rip

fence housing – then slide each screw

forward to the locations shown.

B. Place facing block 3 over screws.

C. Place washers over screw threads.

D. Thread and tighten the nuts onto the

screws.

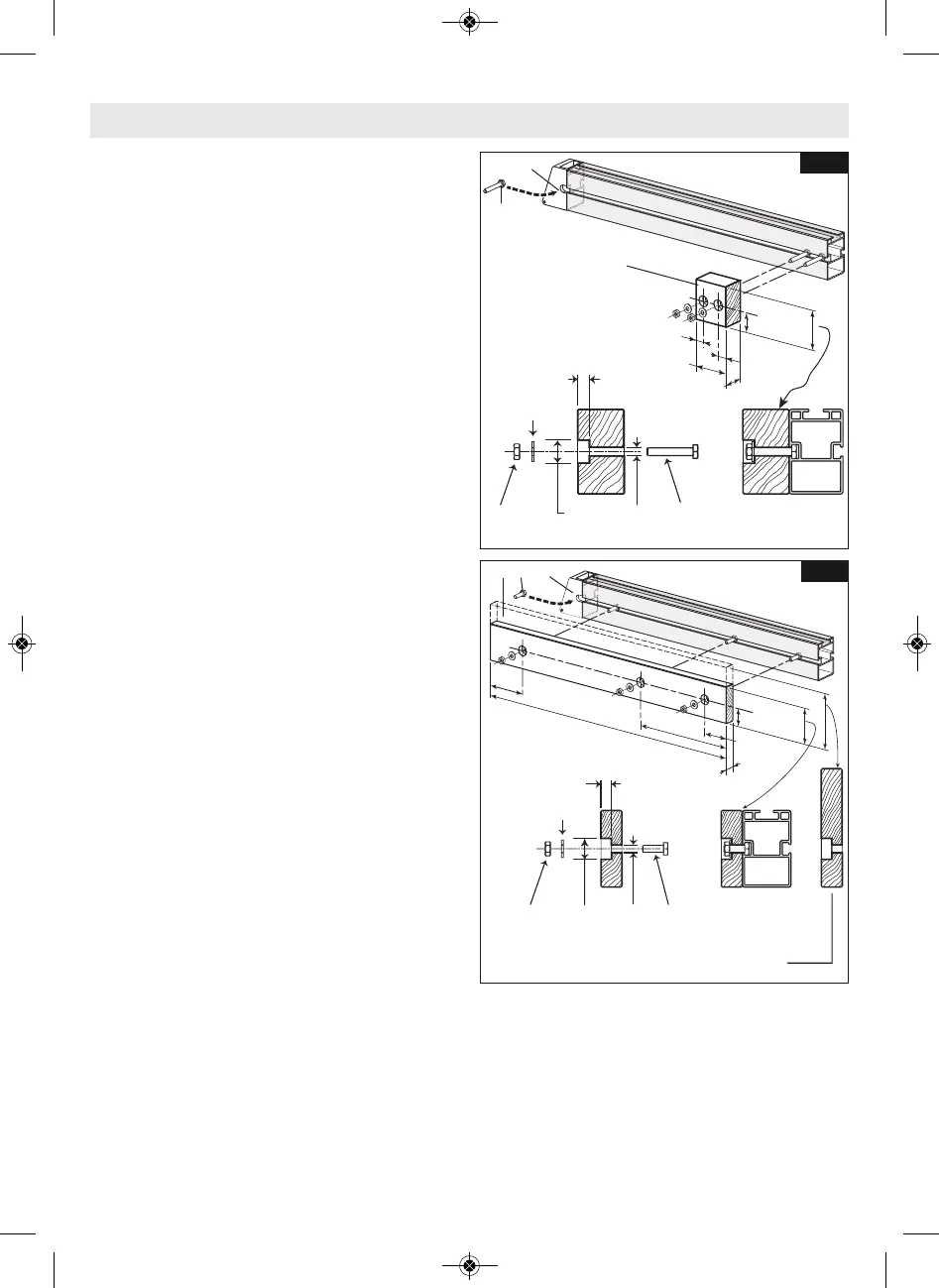

MAKING RIP FENCE AUXILIARY FACING

When using dado or molding head acces-

sories, an auxiliary facing board should be

used. This will help prevent damage to the

aluminum rip fence. The facing should be

made of 3/4 inch (19mm) thick wood – Figure

43 shows dimensional plans to make a facing

board to fit this saw.

Parts Required:

- 3/4" (19mm) thick wood board (solid or

plywood) cut to size

- Three (3) 1/4 x 20 x 3/4" long hex. head

machine screws

- Three (3) 1/4" Washers

- Three (3) 1/4 x 20 machine nuts

The facing is made to the same height (2-3/4"

[70mm]) as the rip fence and can work with

the blade guard system in place when moving

the rip fence to contact the blade. The taller

facing design (4-1/4” [108mm]) is optional

and can be used for clamping on other acces-

sories. Cut the board to the size shown, drill

through 9/32" (7mm) holes, then counter-

sink each hole (down 3/8 inch [9.5mm])

using a 3/4 inch (19mm) drill bit.

Assembly:

A. Place the hex. head 1 of each machine

screw into the recess 2 in the rear rip

fence housing – then slide each screw

forward to the locations shown.

B. Place facing board 3 over screws

C. Place washers over screw threads

D. Thread and tighten the nuts onto the

screws.

Basic Table Saw Operation

Loading...

Loading...