Brookeld Engineering Labs., Inc. Page 24 Manual No. M13-167

Manysamplesmustbecontrolledtoaspecictemperatureforviscositymeasurement.When

conditioningasamplefortemperature,besuretotemperaturecontrolthecontainerandspindle

aswellasthesample.

Pleaseseeourpublication,“MoreSolutionstoStickyProblems”,formoredetailrelatingto

sample preparation.

III.3 Selecting a Spindle/Speed

TheDV2Thasthecapabilityofmeasuringviscosityoveranextremelywiderange.Forexample,

theDV2TRVcanmeasureuidswithintherangeof100-40,000,000cP.Thisrangeisachieved

throughtheuseofseveralspindlesovermanyspeeds.SeeAppendixBfordetails.

Theprocessofselectingaspindleandspeedforanunknownuidisnormallytrialanderror. An

appropriate selection will result in measurements made between 10-100 on the instrument %

torque scale.Twogeneralruleswillhelpinthetrialanderrorprocess.

1)Viscosityrangeisinverselyproportionaltothesizeofthespindle.

2)Viscosityrangeisinverselyproportionaltotherotationalspeed.

Inotherwords:tomeasurehighviscosity,chooseasmallspindleand/oraslowspeed.Ifthechosen

spindle/speedresultsinareadingabove100%,thenreducethespeedorchooseasmallerspindle.

Experimentation may reveal that several spindle/speed combinations will produce satisfactory

resultsbetween10-100%.Whenthiscircumstanceoccurs,anyofthespindlesmaybeselected.

Non-Newtonianuidbehaviorcanresultinthemeasuredviscosityandyieldstresschangingifthe

spindleand/orspeedischanged.Seeourpublication,“MoreSolutionstoStickyProblems”,for

more details.

When viscosity data must be compared, be sure to use the same test methodology: namely the

same instrument, spindle, speed, container, temperature and test time.

DV2TLVViscometersareprovidedwithasetoffourspindlesand

anarrowguardleg;DV2TRVViscometerscomewithasetofsix

spindlesandawiderguardleg;DV2THAandDV2THBViscometers

comewithasetofsixspindlesandno guardleg. (See Appendix

Fformoreinformationontheguardleg.)

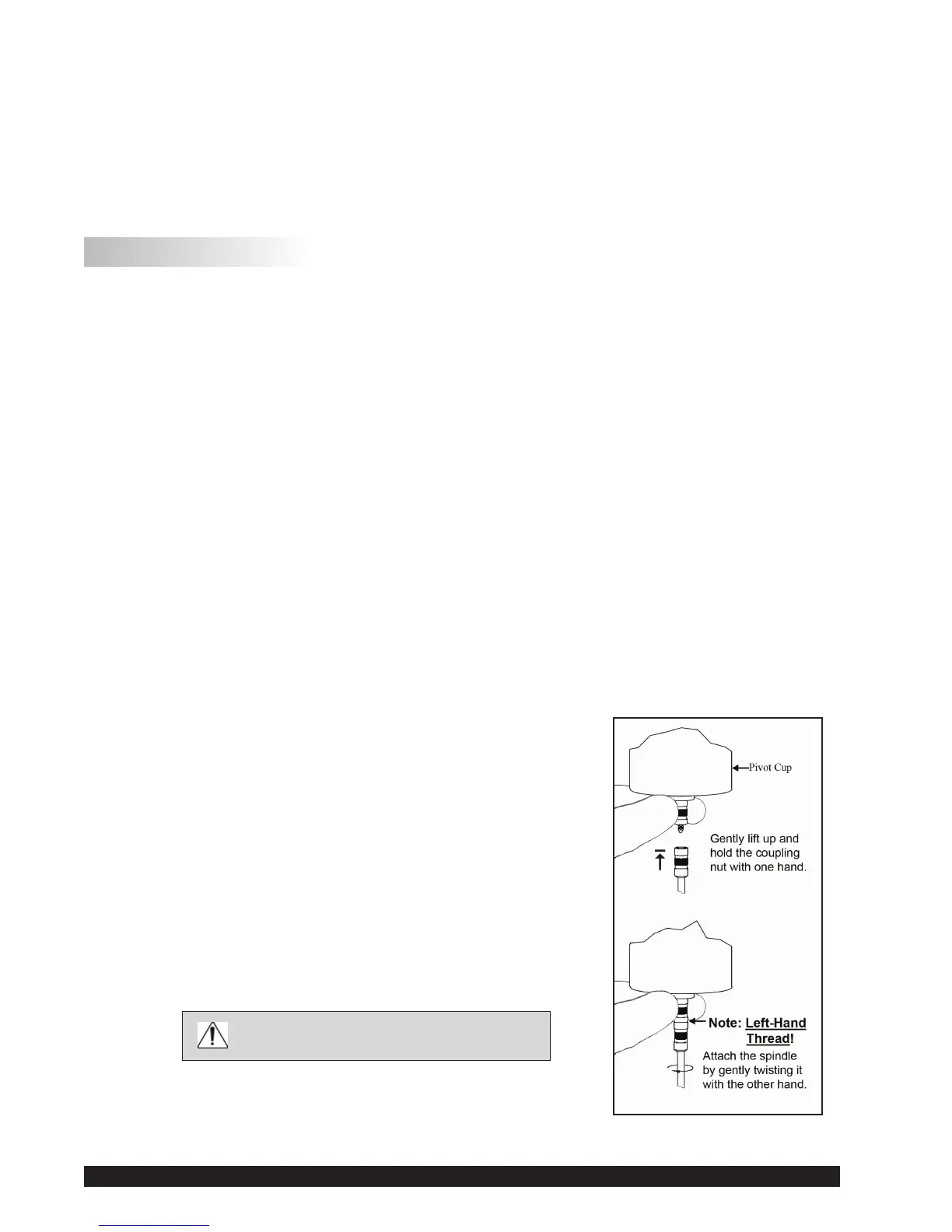

The spindles are attached to the viscometer by screwing them

ontothecouplingnutonthelowershaft(seeFigureIII-1).Note

thatthespindleshavealeft-handthread.Thelowershaftshould

besecuredandslightlyliftedwithonehandwhilescrewingthe

spindletotheleft.Thefaceofthespindlenutandthematching

surfaceonthelowershaftshouldbesmoothandcleantoprevent

eccentricrotationofthespindle.Spindlescanbeidentiedbythe

numberonthesideofthespindlecouplingnut.

ThemotorshouldbeOFF whenever

spindlesarebeingremovedorattached.

Figure III-1

Loading...

Loading...