9. Standard adjutsments

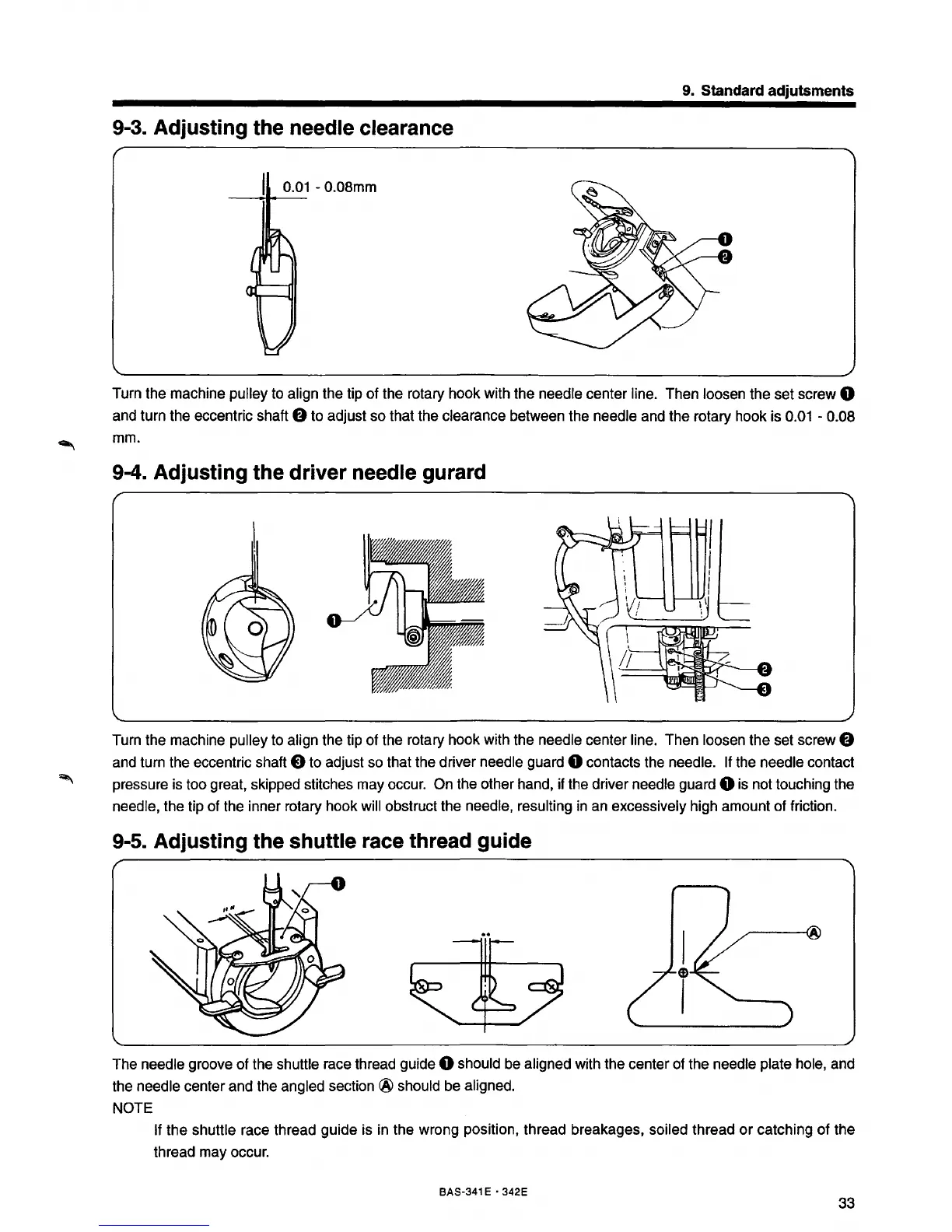

9-3. Adjusting the needle clearance

I

0.01

-

O.OBmm

Turn the machine pulley

to

align the tip of the rotary hook with the needle center line. Then loosen the set screw 0

and

turn the eccentric shaft 8 to adjust so that the clearance between the needle

and

the rotary hook is

0.01

- 0.08

mm.

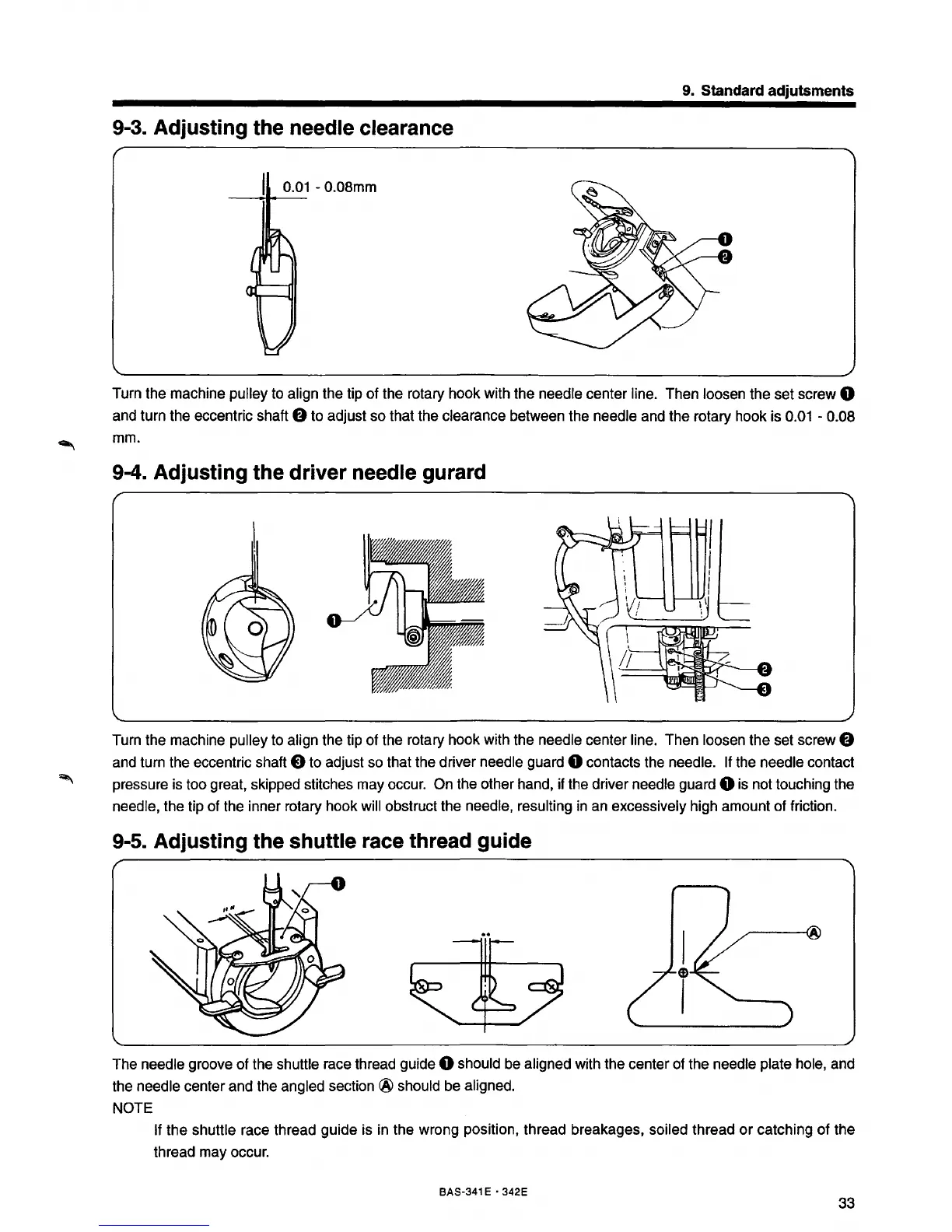

9-4. Adjusting the driver needle gurard

Turn the machine pulley to align the tip of the rotary hook with the needle center line. Then loosen the set screw 8

and

turn the eccentric shaft 8 to adjust

so

that the driver needle guard 0 contacts the needle. If the needle contact

pressure

is

too great, skipped stitches may occur.

On

the other hand,

if

the driver needle guard 0 is not touching the

needle, the tip of the inner rotary hook will obstruct the needle, resulting

in

an

excessively high amount of friction.

9-5. Adjusting the shuttle race thread guide

I

$

I

The needle groove of the shuttle race thread guide 0 should

be

aligned with the center of the needle plate hole, and

the needle center and the angled sec:tion@ should

be

aligned.

NOTE

If the shuttle race thread guide

is

in

the wrong position, thread breakages, soiled thread

or

catching of the

thread may occur.

BAS-341 E • 342E

33

Loading...

Loading...