143

FUEL SYSTEM

FUEL COMPONENT SERVICING

7

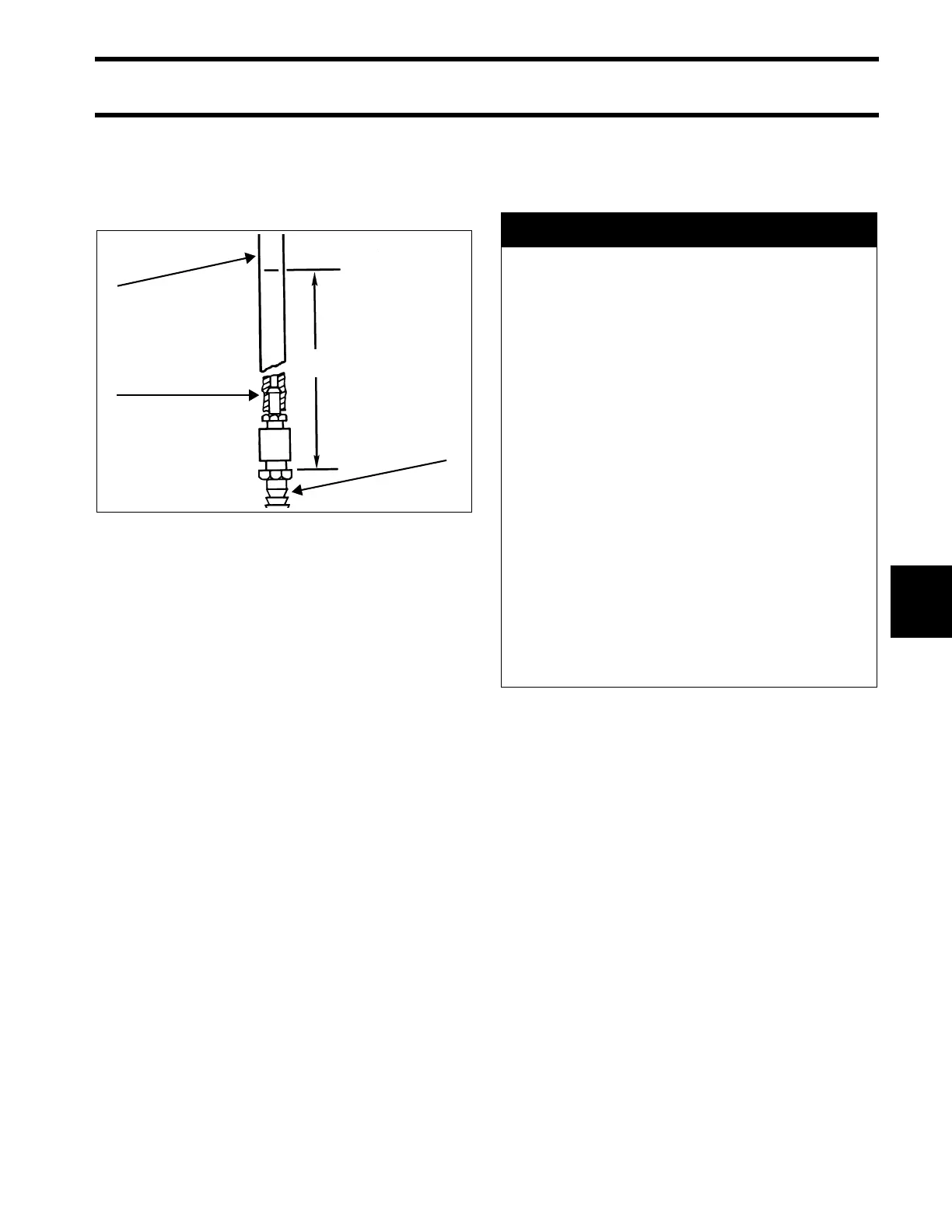

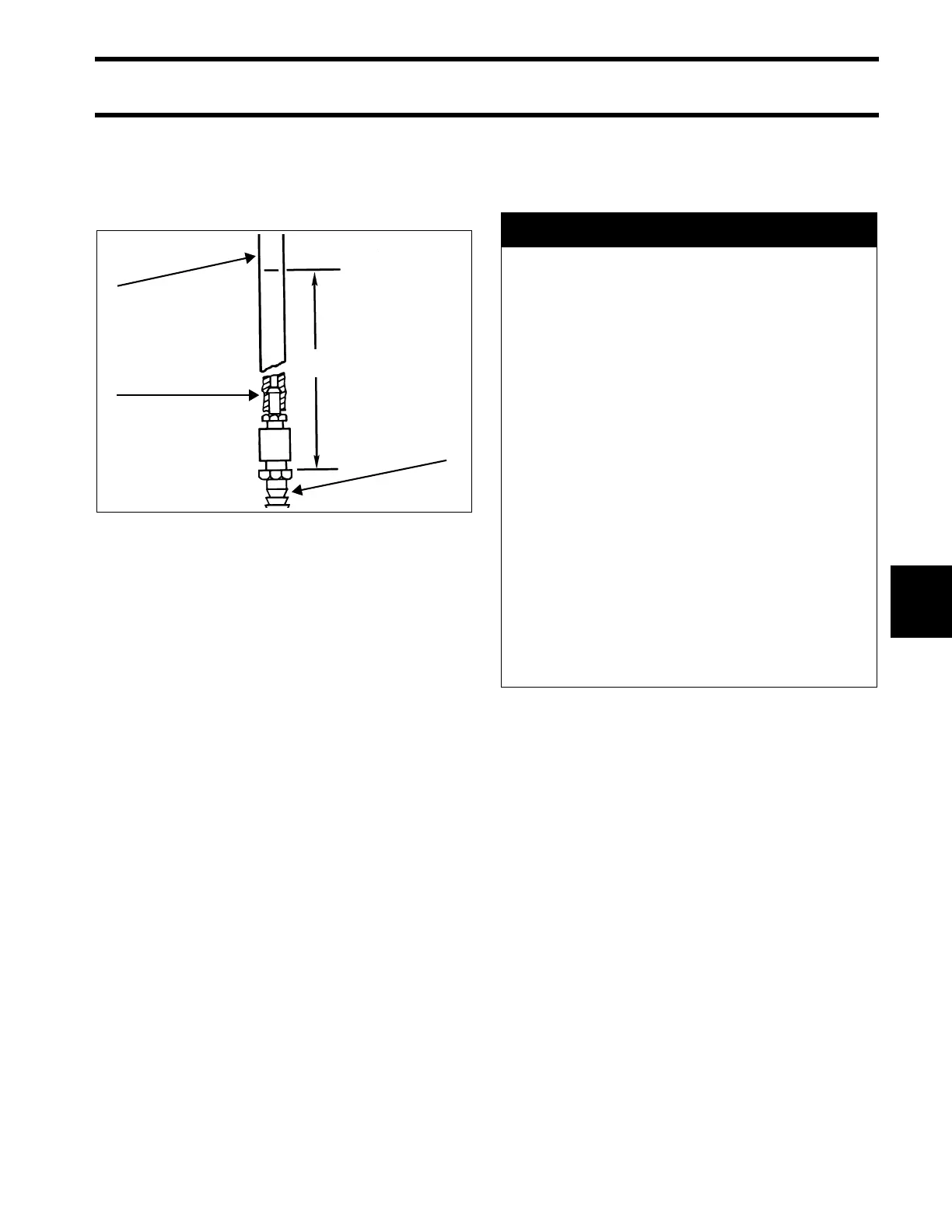

Anti-Siphon Valve Test

Remove anti-sip hon valve from fuel t ank. Inst all

adapter fittings and a 36 in. (91.4 cm) len gth of

clear hose to the inlet side (tank end) of valve.

Fill clear hose with water to a height of 20 in. (500

mm). W ater must NOT flow throug h valve . An

occasional d rip is accep table. Rep lace valve if

water drips continuously.

Increase height of water to 25 in. (630 mm). Water

should flow through valve a s water level re aches

25 in. (630 mm). Replace the anti-siphon valve if

test results are different.

FUEL COMPONENT

SERVICING

Relieving Fuel System Pressure

IMPORTANT: Minimize fue l sy stem pre ssure

prior to disassembly. Temporarily restrict the fue l

supply hose from fuel t ank with hose pincer.

Remove propeller and disco nnect circulation fuel

pump ele ctrical connector. If outb oard runs, start

and run at IDLE for 5 se conds a nd ST OP o ut-

board. If o utboard doe s NOT run, crank for 1 0

seconds.

Disconnect the battery cables at the battery.

1. Anti-siphon valve

2. Adapter fitting

3. Clear hose

DR2277

A WARNING

Gasoline is ex tremely fl ammable and

highly explosive under certain conditions.

Use caution when working on any part of

the fuel system.

Protect aga inst hazardous fuel s pray.

Before st arting any fuel syste m service,

carefully re lieve fuel sys tem pressure.

Refer to Relieving Fuel System Pressure.

Always disco nnect the batte ry cables at

the batte ry befo re servicing the fuel sys-

tem unless instructed to do otherwise.

Always work in a well v entilated area and

wipe off any fuel spillage.

DO NOT smoke and make certain no open

flames or ignition sources exist.

After servicing the fuel system check for

leaks. Failure to c heck for fuel le akage

could allow a l eak to go unde tected,

resulting in fire or explosion.

Loading...

Loading...