288

GEARCASE

GEARCASE LEAK TEST

If cotter pin holes in t he nut (without keeper) and

shaft do not align, tighten further. Do not loosen.

Install keeper (if applicable). Install new cotter pin.

IMPORTANT: After inst allation, make sure out-

board is in NEUTRAL and carefully spin propeller.

Propeller must turn freely and sh ould not spin off

center. If propeller app ears to wobble, check for

possible bent propeller shaft.

GEARCASE LEAK TEST

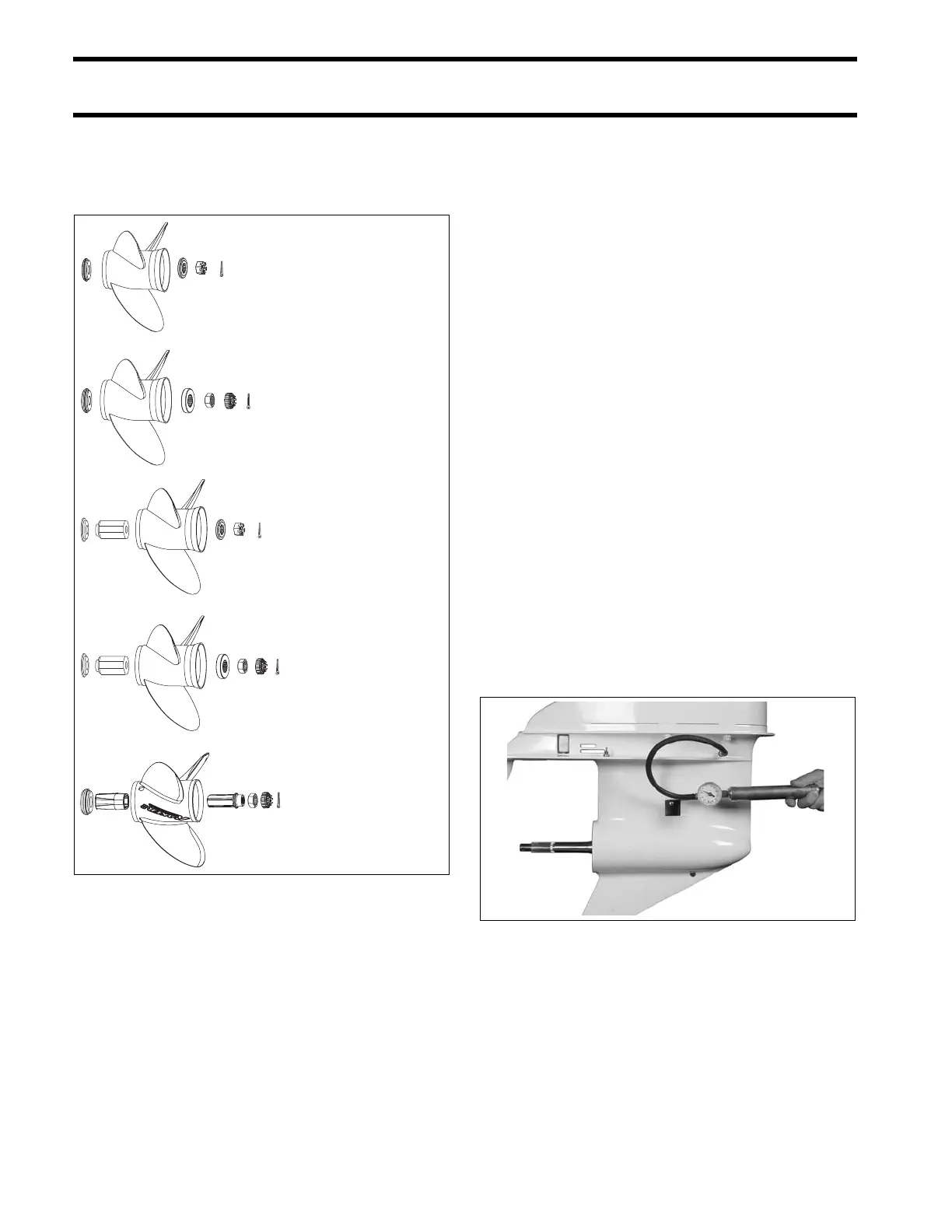

Drain lubricant before testing.

Use Gearcase Pressure Tester, P/N 507977.

Install lubricant drain/fill p lug and seal, thre ad

pressure test g auge fitting a nd seal in lubricant

level hole.

Pressurize 3 to 6 psi (21 to 42 kPa).

If pressure gauge indicates lea kage, submerge

the gearcase in water to determine source of leak.

If th e gauge does not in dicate le akage, increase

pressure to 16 to 18 psi (110 to 124 kPa). Check

for leaks.

Make necessary repairs and repeat test.

Install Gearca se V acuum T ester, P/N 507982.

Apply 3 to 5 in. of vacuum (76 to 127 mm) Hg.

with pump.

If vacuu m gaug e indicat es le akage, apply oil

around suspect ed seal. If lea k stop s or oil is

drawn in, seal is defective.

Repeat test, g earcase must ho ld minimum o f 15

in. vacuum (381 mm) Hg.

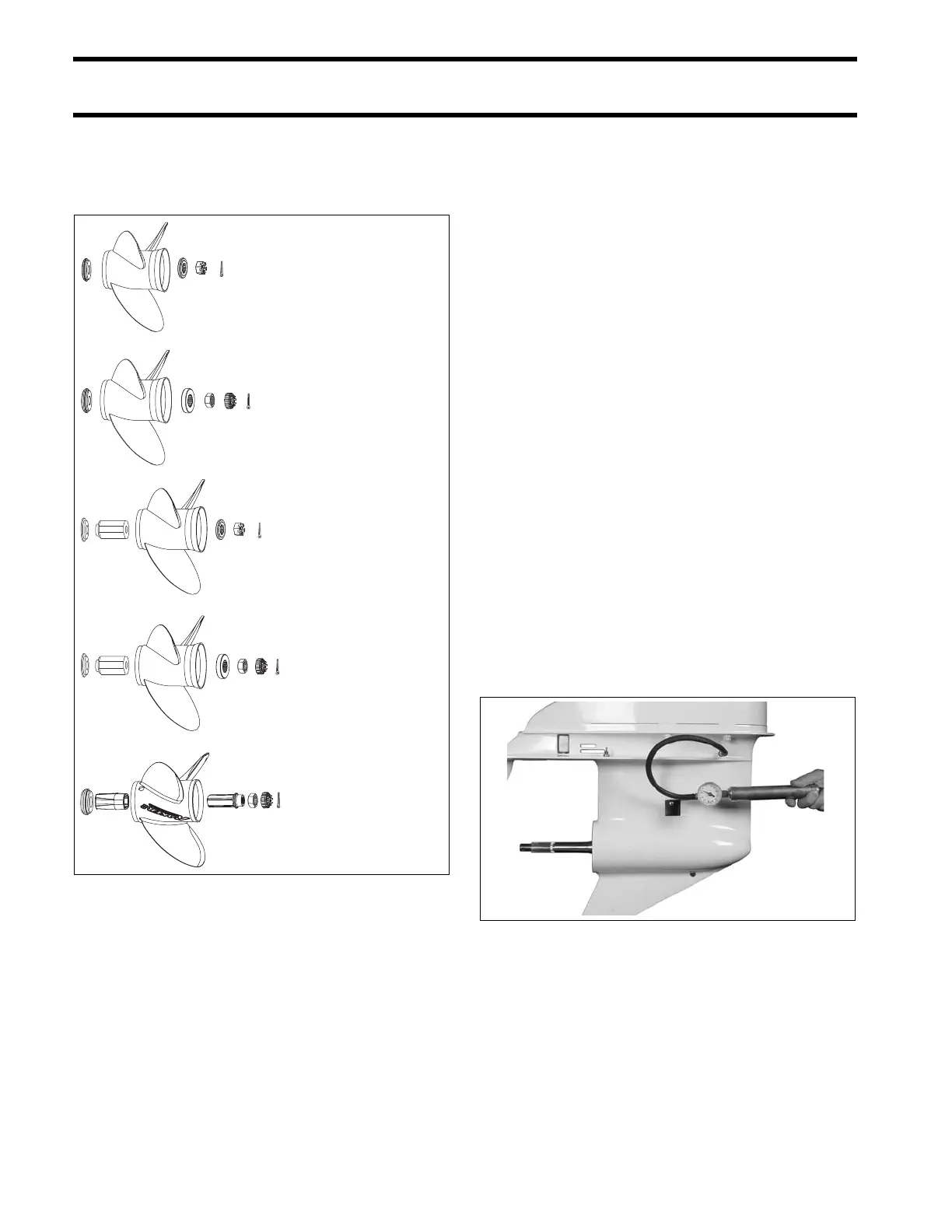

1. Thrust bushing

2. Spacer

3. Propeller nut

4. Keeper

008057

Aluminum or stainless steel

Small diameter hub

Without keeper

120 to 144 in. lbs

Aluminum or stainless steel

Large diameter hub

With keeper

70 to 80 ft. lbs

Aluminum interchangeable hub

Small diameter hub

Without keeper

120 to 144 in. lbs

Aluminum interchangeable hub

Large diameter hub

With keeper

70 to 80 ft. lbs

Stainless steel TBX hub

Large diameter hub

With keeper

70 to 80 ft. lbs

002388

Loading...

Loading...