340

TRIM AND TILT

ROUTINE INSPECTIONS

ROUTINE INSPECTIONS

General

Check for exte rnal signs of fluid leakage. Correct

causes as necessary.

Check the b attery and make sure it is in go od

operating condition.

Reservoir Fluid

Check reservo ir fluid level every th ree yea rs or

every 300 opera ting ho urs. System cap acity is

approximately 21 fl. oz. (620 ml).

Refer to Trim and T ilt on p. 39 for filling proce-

dure.

Manual Release Valve

Check the manual release valve with a torq ue

wrench.

IMPORTANT: Tighten valve to a torque of 45 to

55 in. lbs. (5 to 6 N·m).

Stern Brackets

Inspect the stern brackets for binding.

Tighten starboard tilt tube nut to a torque of 45 to

50 ft. lbs. (61 to 68 N·m).

TROUBLESHOOTING

If the power trim/tilt system has malfunctioned and

the cause h as not been d etermined, th e Symp-

toms Chart on p. 341 should help locate the

problem.

Keep a manual release valve and a valve body in

stock for troublesho oting. Use these p arts whe n

the Service Proce dures on p. 341 call fo r t he

substitution of known good parts.

If the trim/tilt does not work, and its motor neither

runs nor hums, troubleshoot the problem by refer-

ring to TILT/TRIM RELAY TEST on p. 105.

If the outboard tilts part way up but not smoothly,

or with a const ant sound, there is probably air in

the s ystem du e t o l ow fluid. Fi ll re servoir an d

bleed (purge air from) the system.

To test fo r mechanical binding, op en the manua l

release valve and manually tilt the motor up and

down. If parts are binding, refer to MIDSECTION

section.

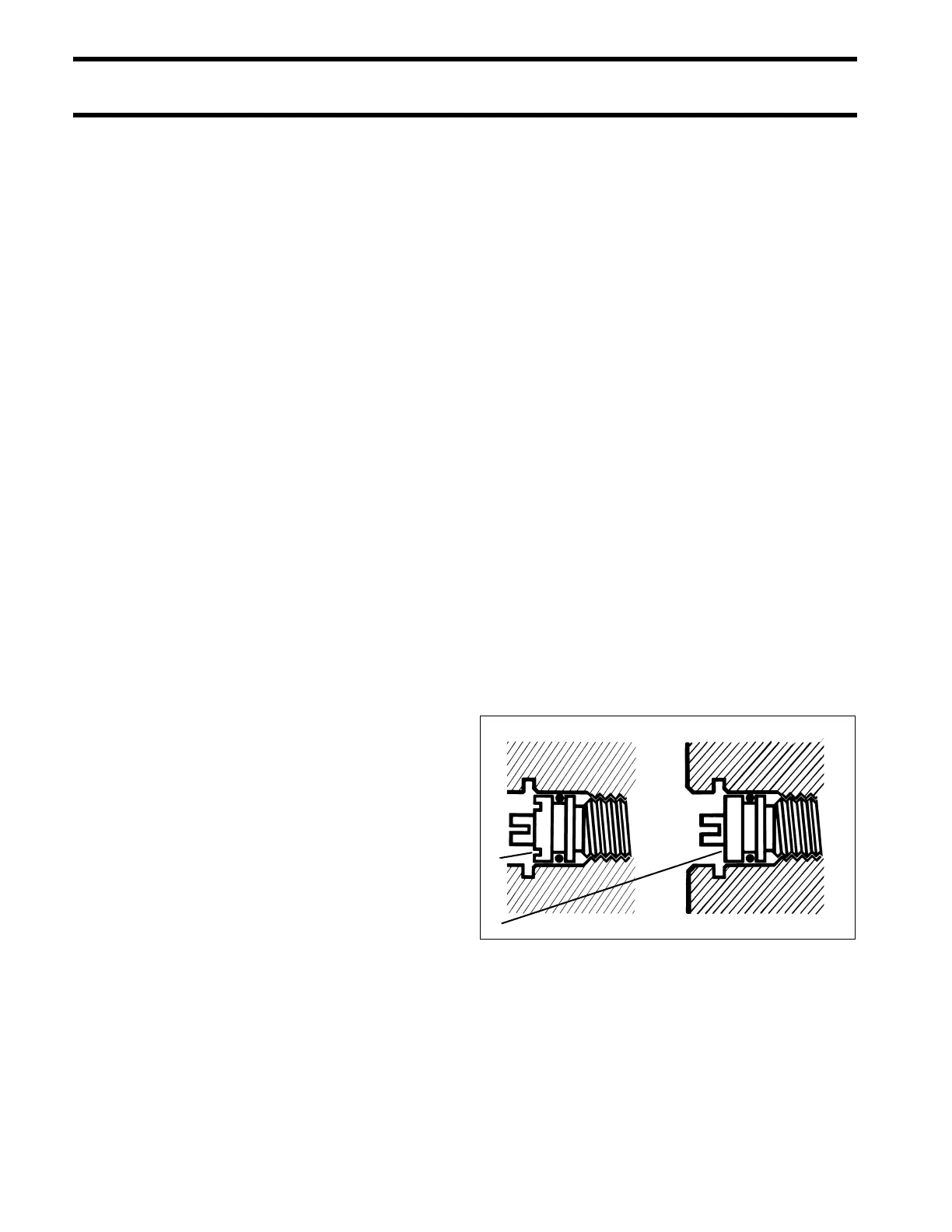

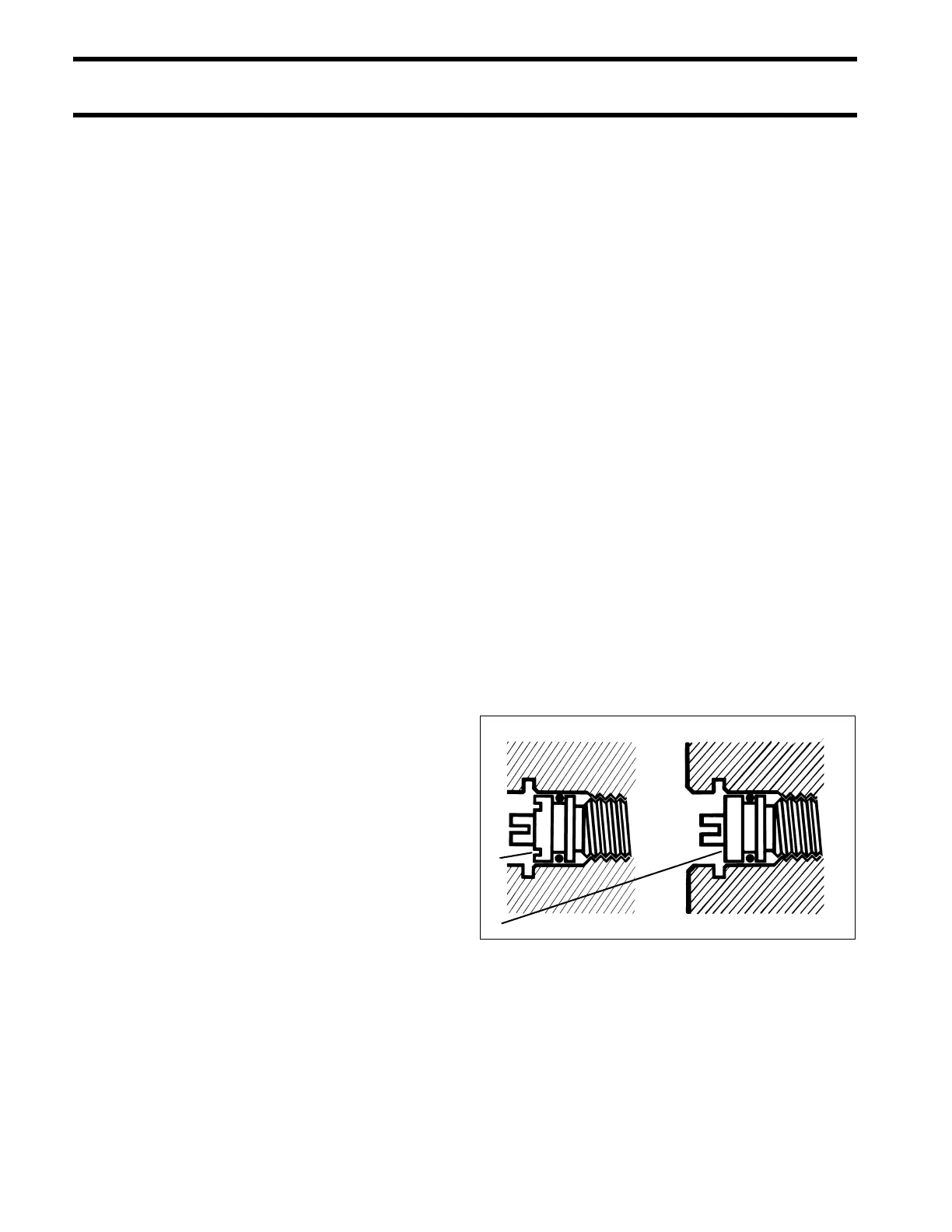

If the outboard will not st ay in shallow water drive

and drops down at fast idle, the wrong manual

release valve may be inst alled. Check f or th e

identification groove in the face of the valve.

1. Grooves (V4 Models)

2. No grooves (V6 Models)

30959

Loading...

Loading...