94

ELECTRICAL AND IGNITION

SENSOR TESTS

SENSOR TESTS

All senso r circu its a re de pendent o n wiring a nd

connections, EMM supplied current (5 V), and

sensor resist ance. The supplied current flows

through the wiring circuit and sensor be fore

returning to the EMM.

IMPORTANT: Use Evinrude Diagnostics sof t-

ware to monitor sensor circuit voltages or values.

Crankshaft Position Sensor (CPS)

Test

Use the Evinrude Diagnostics software CPS Sync

and engine RPM displays to confirm a valid CPS

signal while the outboa rd is cranking or running.

An RPM display higher than zero indicates a CPS

signal to the EMM.

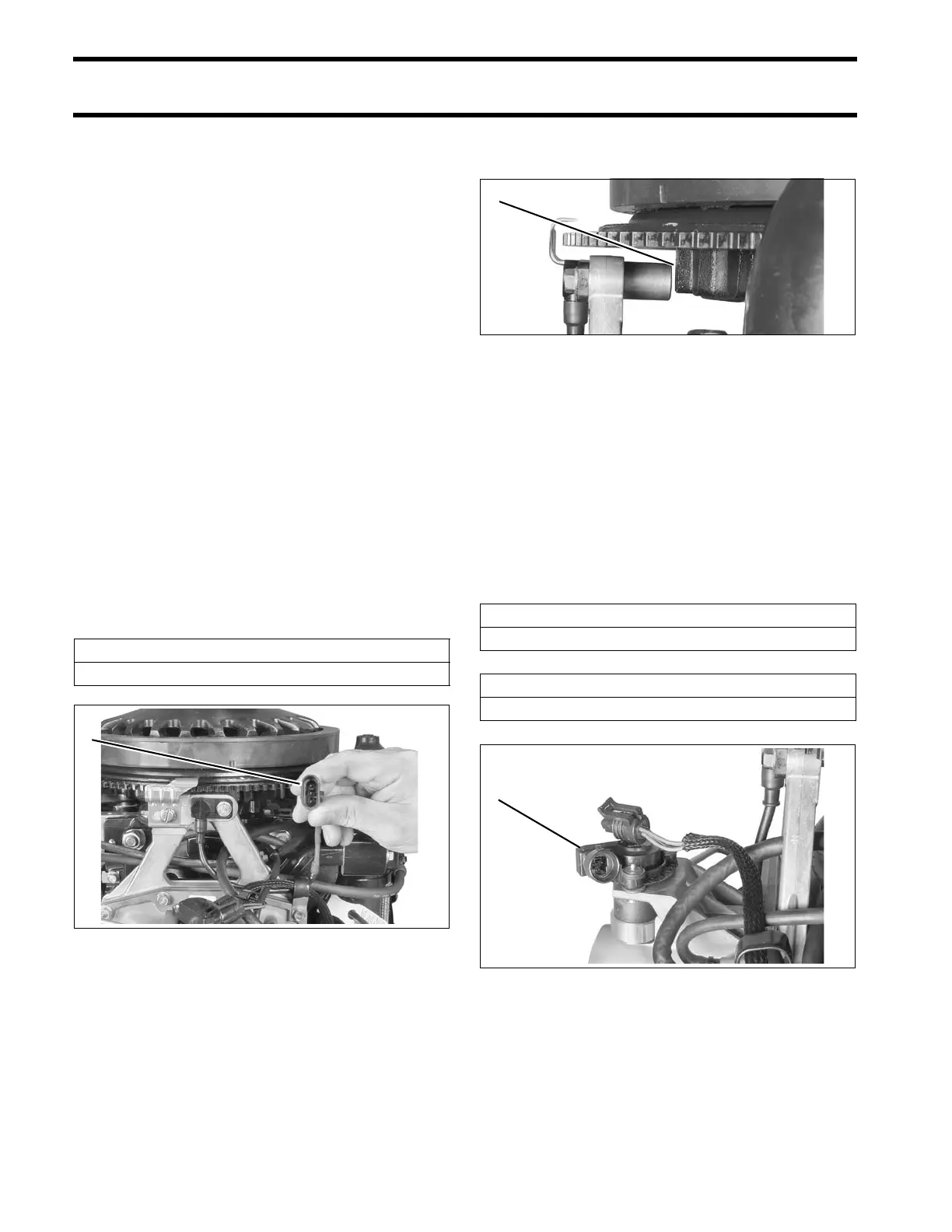

Disconnect the crankshaft position sensor.

Use a digital multimeter to measure sensor resis-

tance betwee n the yellow a nd white wires. The

complete circuit can b e tested by measuring

between pins 6 and 7 of the EMM J1-A connector.

.

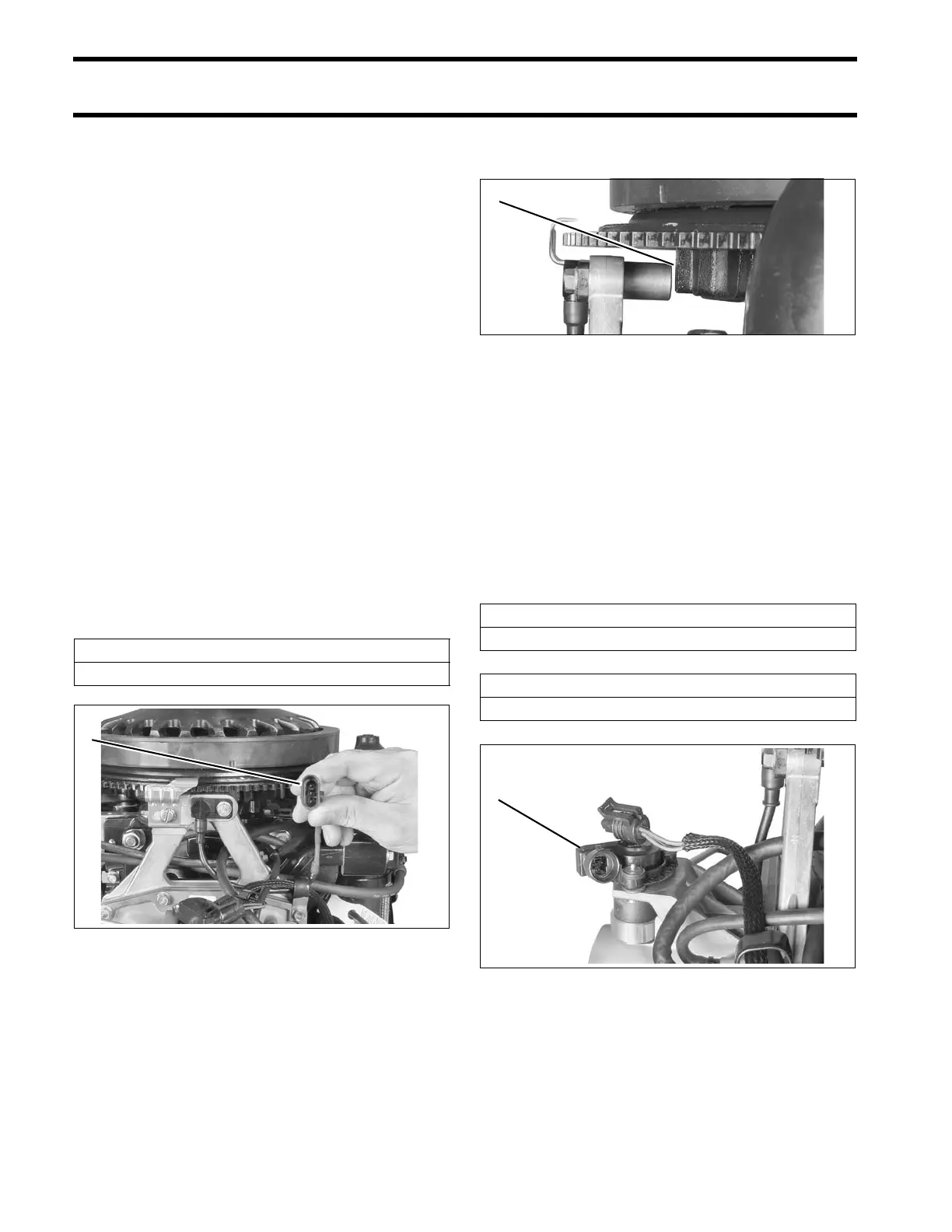

The CPS is mounted to throttle body housing and

requires no adjustment. Air gap or cleara nce to

flywheel is fixed at ap proximately 0 .073 in.

(1.85 mm). Th e accep table clearance is 0 .036 to

0.110 in. (1 to 2.8 mm).

Throttle Position Sensor (TPS) Test

Use Evinrude Diagnostics sof tware to monitor

TPS volt age while the ou tboard is running. Volt-

age sho uld change evenly as se nsor lever is

moved.

Remove the electrical co nnector from the throttle

position sensor.

Use a digital multimeter to measure sensor re sis-

tance.

Sensor Resistance

560 W ± 10% @ 77°F (25°C)

1. CPS Connector 004199

1. CPS gap 004200

Sensor Resistance (between “A” and “B”)

3000 to 7000 W @ 77°F (25°C)

Sensor Resistance (between “A” and “C”)

4000 to 8000 W @ 77°F (25°C)

1. TPS 004256

Loading...

Loading...