229

POWERHEAD

POWERHEAD INSPECTION

11

Cylinder Bore

Use a Cylinder Bore Gauge to inspect each cylin-

der bore for an out-of-round, oversize, or t apered

condition. Be sure the gauge is perfectly square in

the bore when measuring.

Measure each cylinder in at least two areas. Each

area should be measured twice. The dif ference

between th e two measurement s in each a rea is

the cylinder out-of-round dimension.

• The cylinder must not be out-of-round by more

than 0.004 in. (0.10 mm).

The dimensional dif ference between the two

areas is cylinder taper.

• The cylind er t aper must n ot exceed 0.002 in.

(0.05 mm).

The difference between the measurement s and

standard bore is cylind er oversize. For dimen-

sions, refer to SERVICE S PECIFICATIONS on

p. 10.

• The cylinder must not be oversized by more

than 0.003 in. (0.08 mm).

Pistons

Visually inspect pisto ns for signs o f abn ormal

wear, scuffing, cracks, or burning.

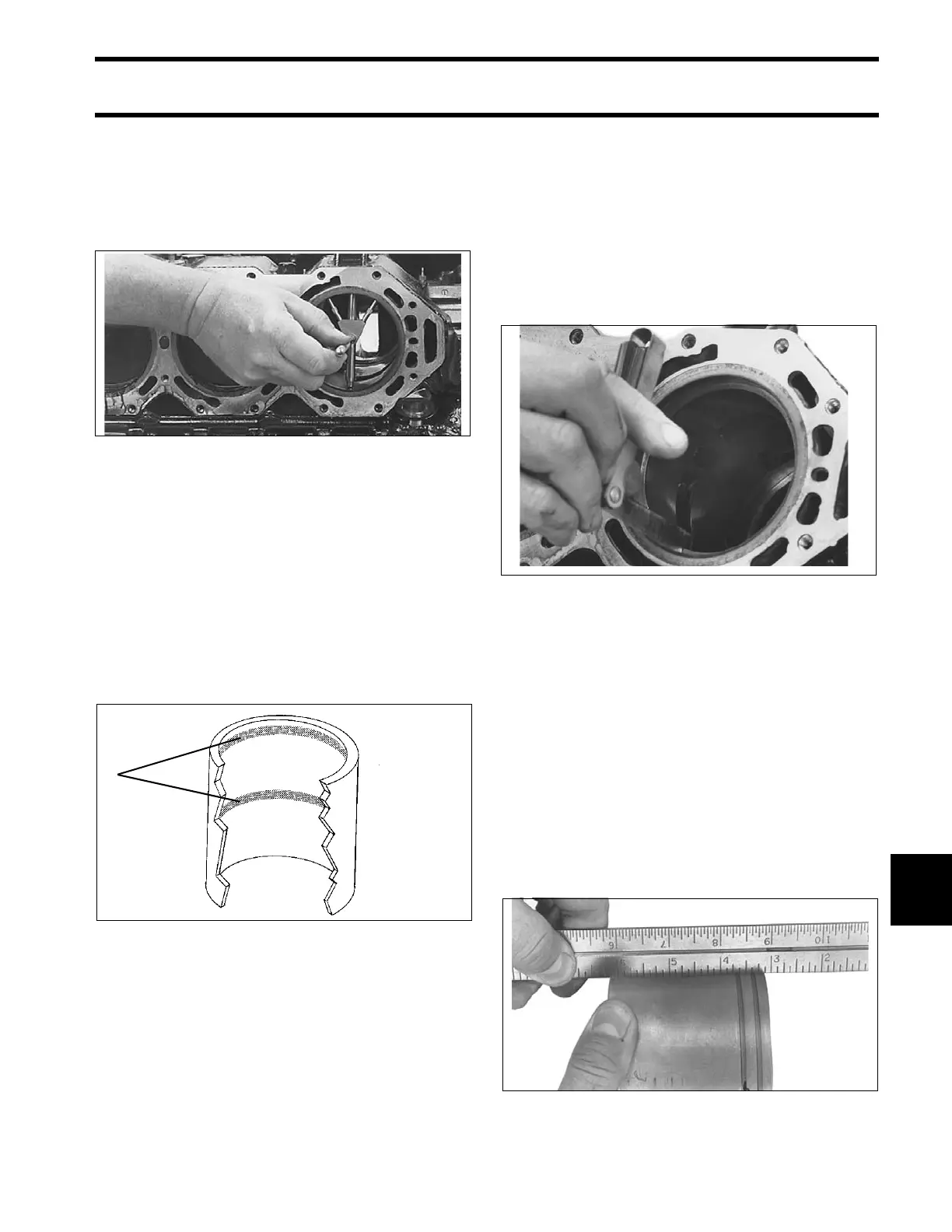

Piston Rings

For new ring sets, place each ring separately in its

respective bore. Use a piston to square the ring in

the cylinder. Use a feeler ga uge to me asure the

ring end gap.

Ring end gap should be:

• 0.022 to 0.028 in. (0.56 to 0.71 mm)

IMPORTANT: Ring end g ap increases ap proxi-

mately 0.003 in. (0. 076 mm) for e ach 0 .001 in.

(0.025 mm) incre ase in cylinder bor e diamete r.

DO NOT exceed cylinder oversize dimension.

Use a machinist’s straightedge to check for proper

ring clea rance. Position piston rings o n p iston.

Push rings into groove and hold straightedg e

against the side of the piston. Rings must be even

or just be low the surface of piston . Rings must

move freely in piston ring groove.

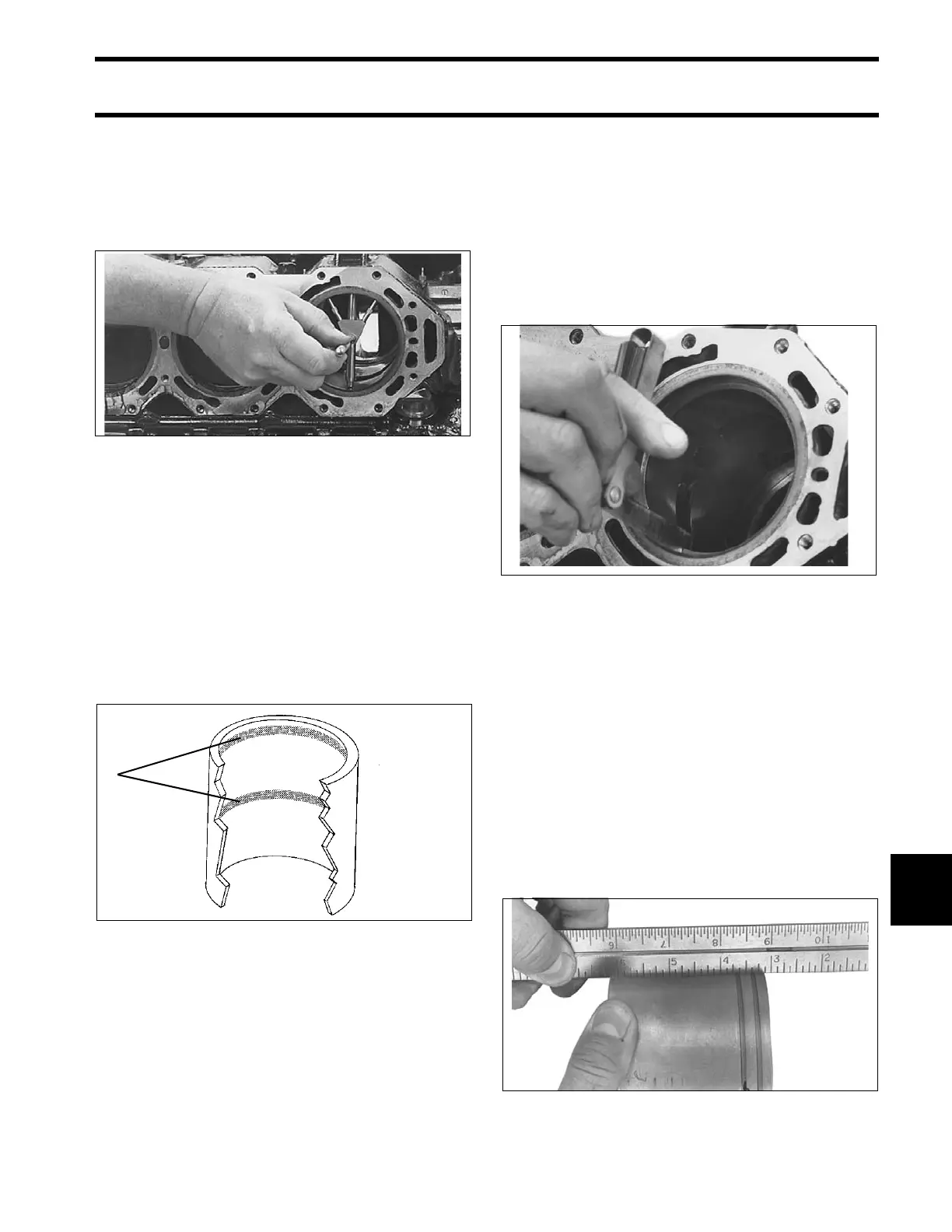

Measure as shown 49427

1. Cylinder taper DR1119

49433

31796

Loading...

Loading...