296

GEARCASE – STANDARD ROTATION

GEARCASE DISASSEMBLY

GEARCASE – STANDARD ROTATION

GEARCASE

DISASSEMBLY

Pre-Disassembly Inspection

IMPORTANT: Clean and inspect all parts during

disassembly. Replace an y damaged parts, seals,

O-rings, and gaskets.

Remove the propeller and mounting hardware.

Drain a nd inspect o il as d escribed in Gearcase

Lubricant on p. 37.

Remove gearcase as de scribed in GEARCASE

REMOVAL AND INSTALLATION on p. 289.

Remove water pu mp as d escribed in WATER

PUMP SERVICE on p. 292.

Before disassembling the gearcase, exa mine the

following:

• Gearcase Housing — Check for visible da m-

age to skeg, strut, an ti-ventilation plate , bullet,

and mating surface. Check seal areas for visible

signs of lubricant leakage.

• Propeller Shaft — Check for bent or d amaged

shaft. Check for t wisted sp lines a nd d amaged

threads.

• Shift Rod — Check fo r misad justed, bent, or

binding rod. A misadju sted shift rod height can

cause shift difficulty, loss o f boat an d outboard

control, and gearcase damage.

• Hydrostatic Seal Grooves — Must be in go od

condition to help prevent propeller ventilation.

• Gearcase Anodes — If anodes have eroded to

two-thirds their origina l size, t hey must be

replaced.

• Drive Shaft — Check splin es for visible dam-

age, twisting and wear. Severe spline wear indi-

cates th e exh aust h ousing or ge arcase has

been distorted, possibly by impact damage.

• Water Intake Screen s — Check for damage

and blo ckage. If screens ca nnot b e cleane d,

they mu st be re placed. Dif ferent scre ens a re

available and should not be mixed. Refer to cor-

rect model parts manual for listing and descrip-

tion.

A WARNING

Wear safety glass es to avoid persona l

injury, and set compressed air pressure to

less than 25 psi (172 kPa).

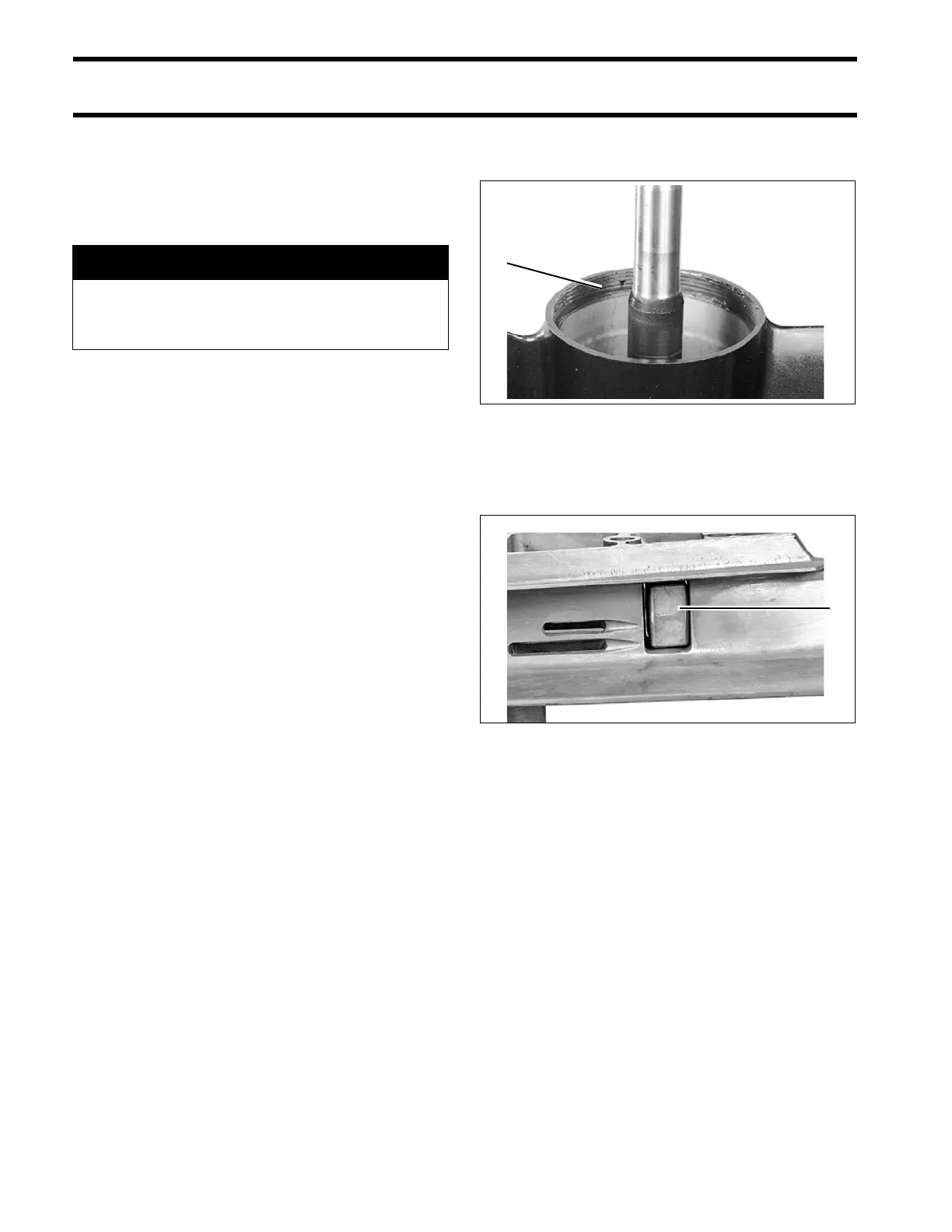

1. Hydrostatic seal grooves 4557

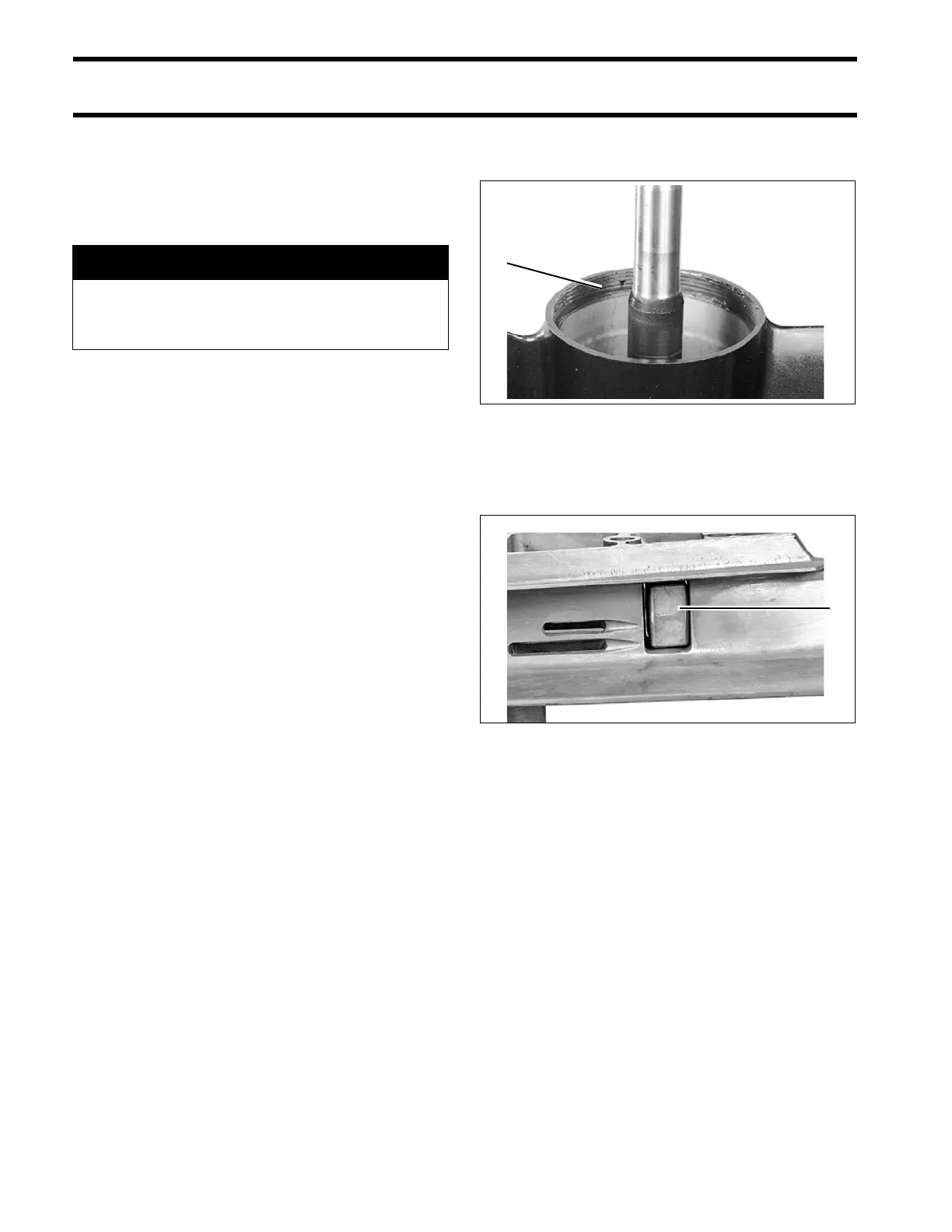

1. Gearcase anode 14161

Loading...

Loading...