1-16

GENERAL INFORMATION

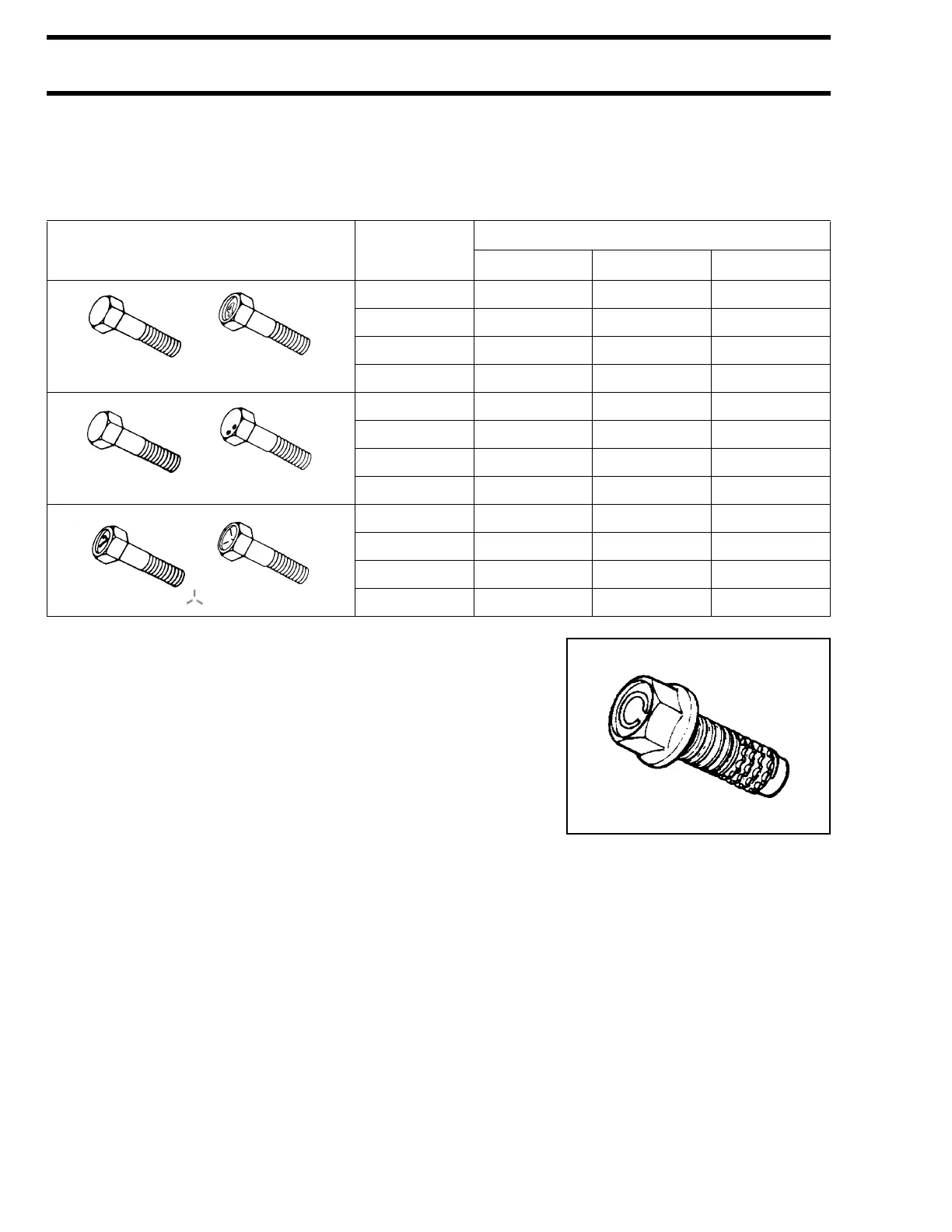

TIGHTENING TORQUE

Tightening torque – general bolt

NOTE:

These values are only applicable when torque for a general bolt is not listed in the “Important Fasteners”

table.

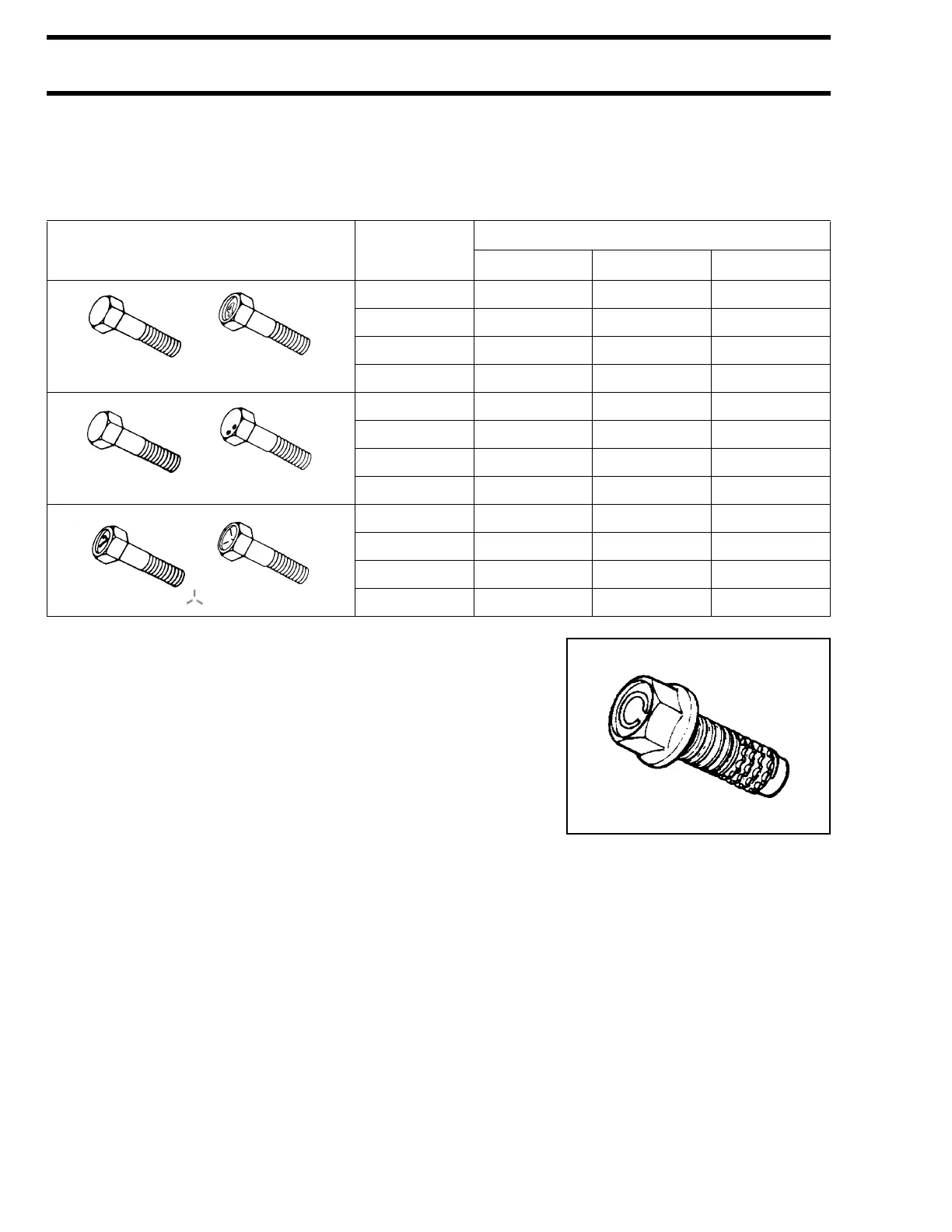

NOTE:

“C” marked self-tapping bolt will tap a thread to an aluminum alloy

part which is replaced by servicing. When installing the self-tap-

ping bolt to a new part, follow the procedure below.

• Tighten the bolt until the bolt head is seated on the secured part

first.

• Completely loosen the bolt.

• Retighten the bolt to the specified torque finally.

TYPE OF BOLT

THREAD

DIAMETER

TIGHTENING TORQUE

N·m kg-m Ib-ft

5 mm 2 – 4 0.2 – 0.4 1.5 – 3.0

6 mm 4 – 7 0.4 – 0.7 3.0 – 5.0

8 mm 10 – 16 1.0 – 1.6 7.0 – 11.5

10 mm 22 – 35 2.3 – 3.5 16.0 – 25.5

5 mm 2 – 4 0.2 – 0.4 1.5 – 3.0

6 mm 6 – 10 0.6 – 1.0 4.5 – 7.0

8 mm 15 – 20 1.5 – 2.0 11.0 – 14.5

10 mm 34 – 41 3.4 – 4.1 24.5 – 29.5

5 mm 3 – 6 0.3 – 0.6 2.0 – 4.5

6 mm 8 – 12 0.8 – 1.2 6.0 – 8.5

8 mm 18 – 28 1.8 – 2.8 13.0 – 20.0

10 mm 40 – 60 4.0 – 6.0 29.0 – 43.5

(Conventional or “4” marked bolt)

(Stainless steel bolt)

(7 marked or marked bolt)

Loading...

Loading...