2-15

PERIODIC MAINTENANCE

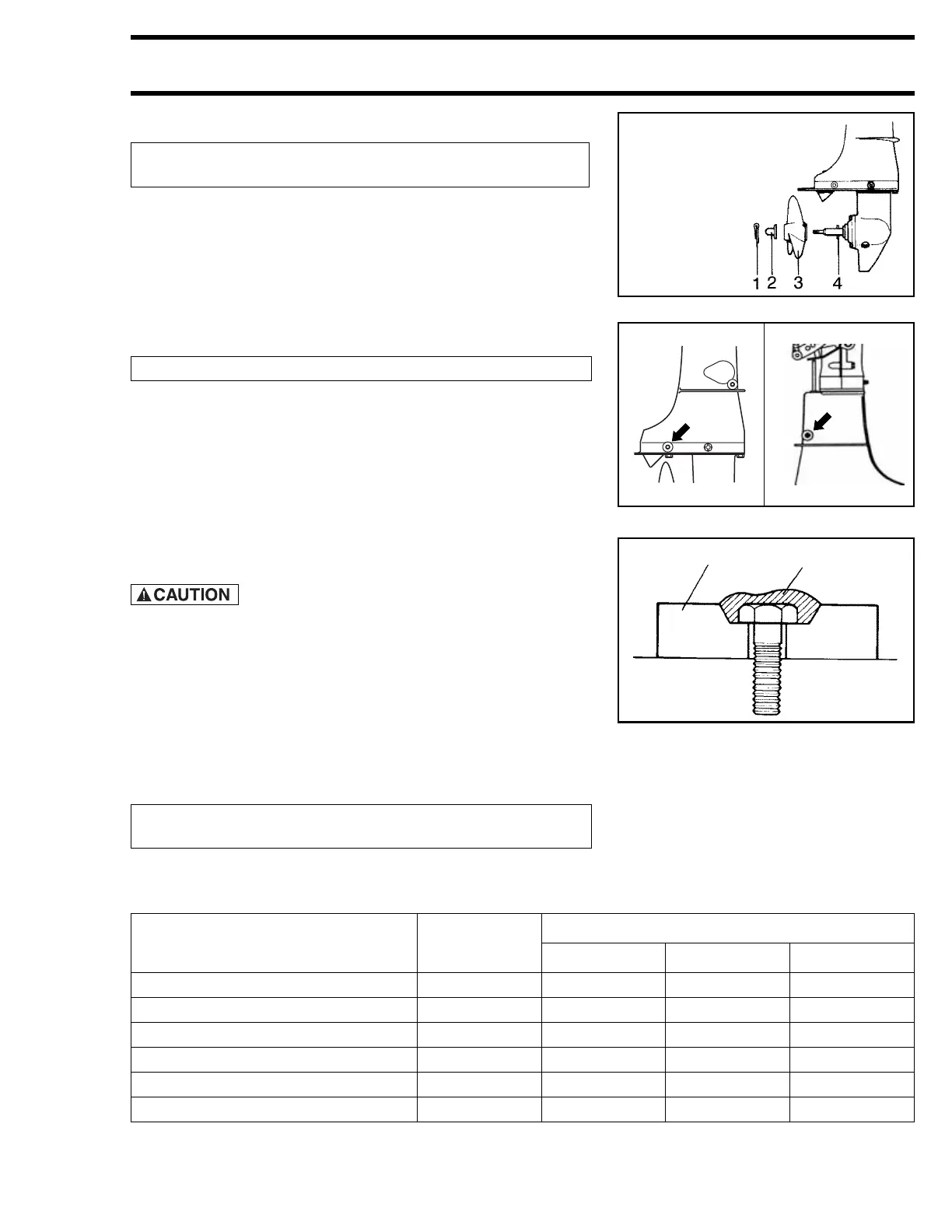

PROPELLER / NUT / COTTER PIN

PROPELLER / NUT / COTTER PIN

• Inspect the propeller for bent, chipped or broken blades. If

damage noticeably affects operation, replace.

• Make sure that the propeller nut is tightened.

• Make sure that the cotter pin is installed securely.

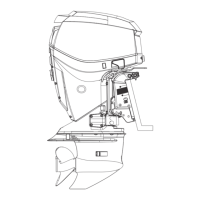

ANODES

If 2/3 of the anode has corroded away, replace the anode.

Do not paint the anode.

NOTE:

Apply the Silicone Seal to the anode securing bolts.

Silicone Seal

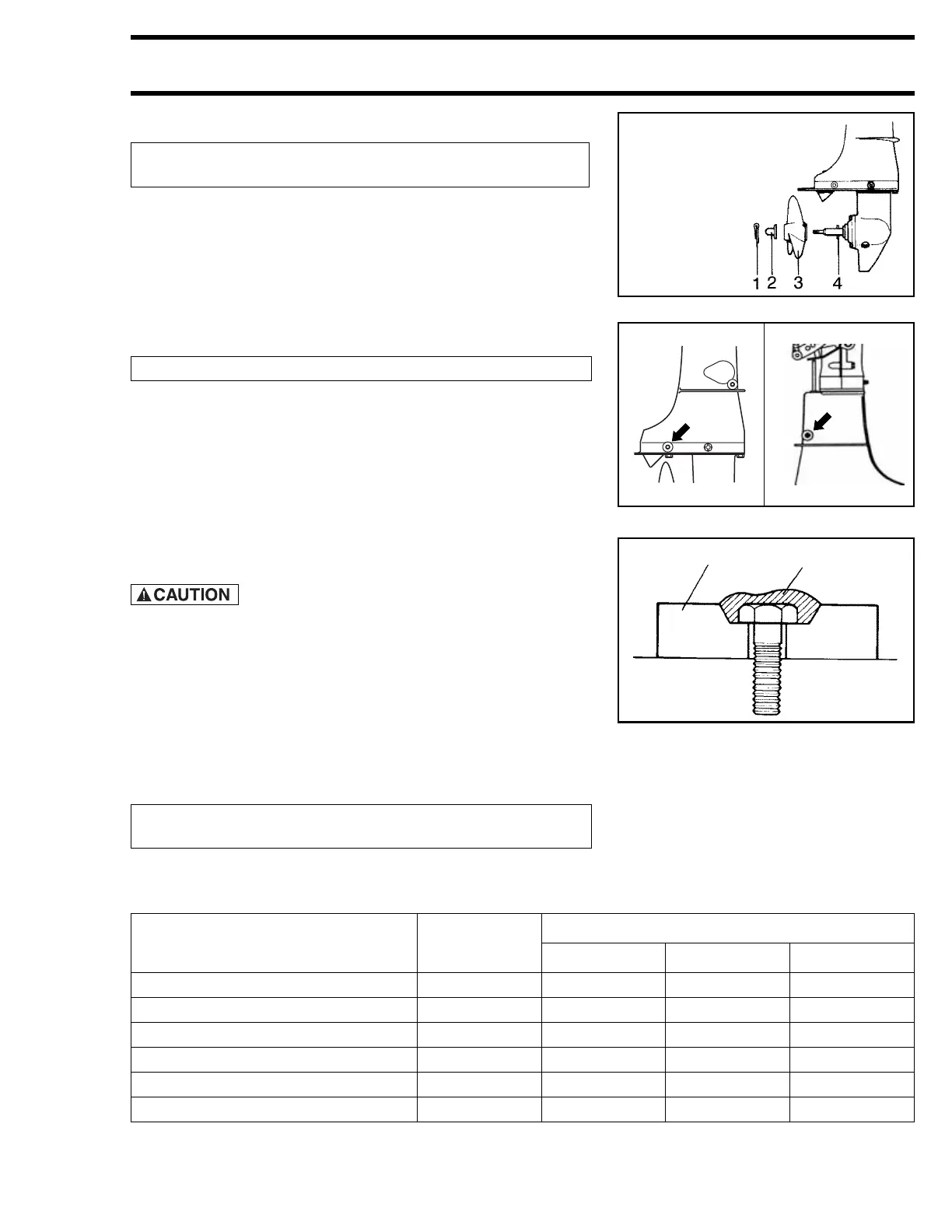

BOLTS AND NUTS

Check that all bolts and nuts listed below are tightened to the

specified torque.

INSPECT INITIALLY AFTER 10 HOURS (1 MONTH)

AND EVERY 100 HOURS (6 MONTHS) THEREAFTER.

INSPECT EVERY 50 HOURS (3 MONTHS).

INSPECT INITIALLY AFTER 20 HOURS (1 MONTH)

AND EVERY 100 HOURS (6 MONTHS) THEREAFTER.

ITEM

THREAD

DIAMETER

TIGHTEN TORQUE

N·m kg-m lb-ft

Cylinder head cover bolt 6 mm 8 0.8 6.0

Cylinder head bolt 8 mm 28 2.8 20.5

Flywheel nut 12 mm 50 5.0 36.0

Powerhead mounting bolt 6 mm 10 1.0 7.0

Clamp bracket shaft nut 10 mm 25 2.5 18.0

Gearcase bolt / nut 8 mm 17 1.7 12.5

1. Cotter pin

2. Propeller nut

3. Propeller

4. Shear pin

Anode

Loading...

Loading...