CryoProbe and Other Accessories

102 / 120 H157654_9_011

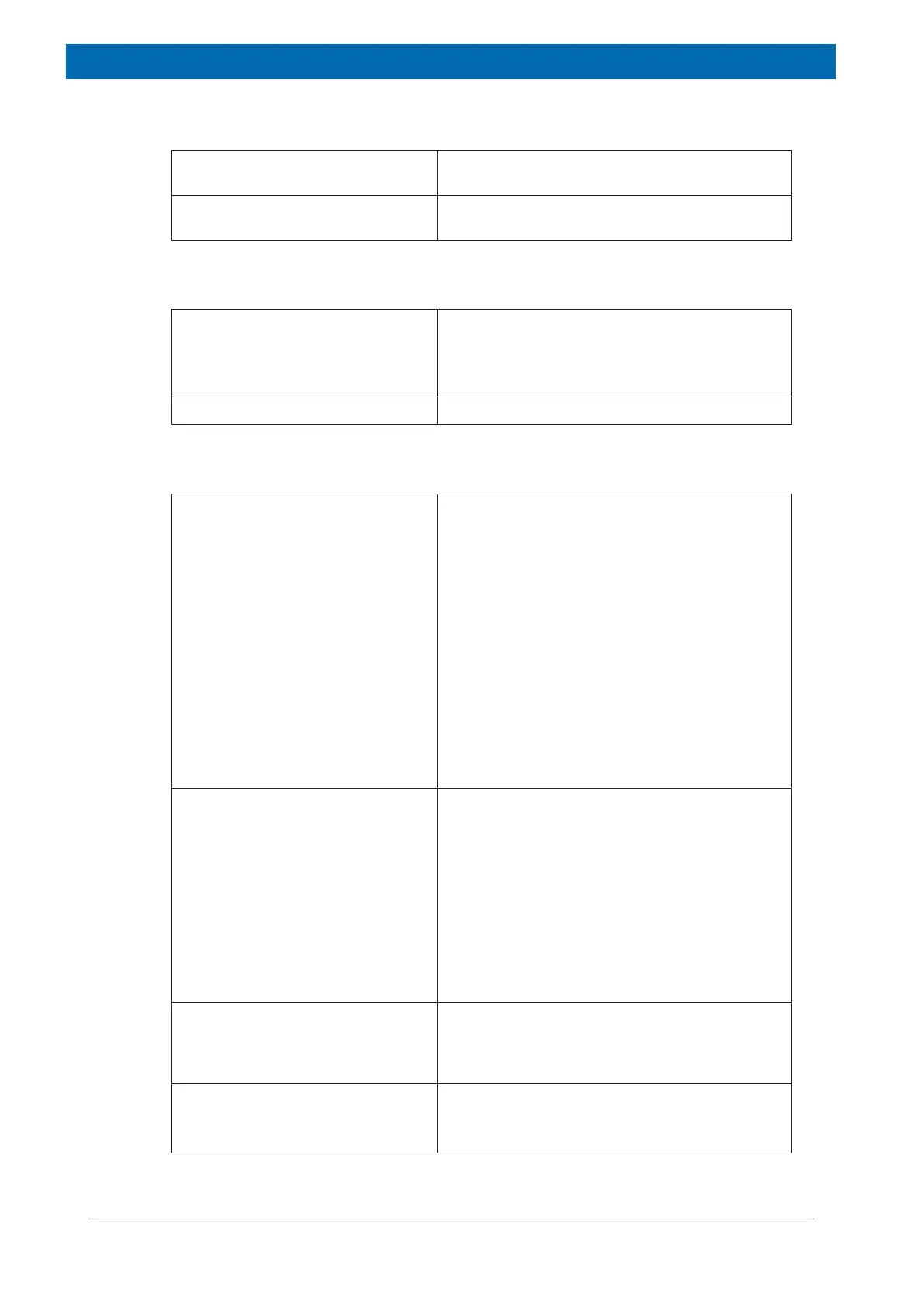

Equipment Dimensions

Prodigy Unit 60 x 40 x 46 cm

3

(L x W x H); add 15 cm for rear

connections.

LN2 Dewar 50 x 62 x 135 cm

3

(L x W x H); width includes de-

war handles.

Table10.5: Prodigy System Equipment Dimensions

Electrical Requirements

Prodigy Unit 100-120 VAC / 50-60 Hz / max. 10 A / max. 0.6

kW.

220-240 VAC / 50-60 Hz / max. 5 A / max. 0.6

kW.

Optional Weight Scale 100-120 VAC or 220-240 VAC / 50-60 Hz.

Table10.6: Prodigy System Electrical Requirements

N

2

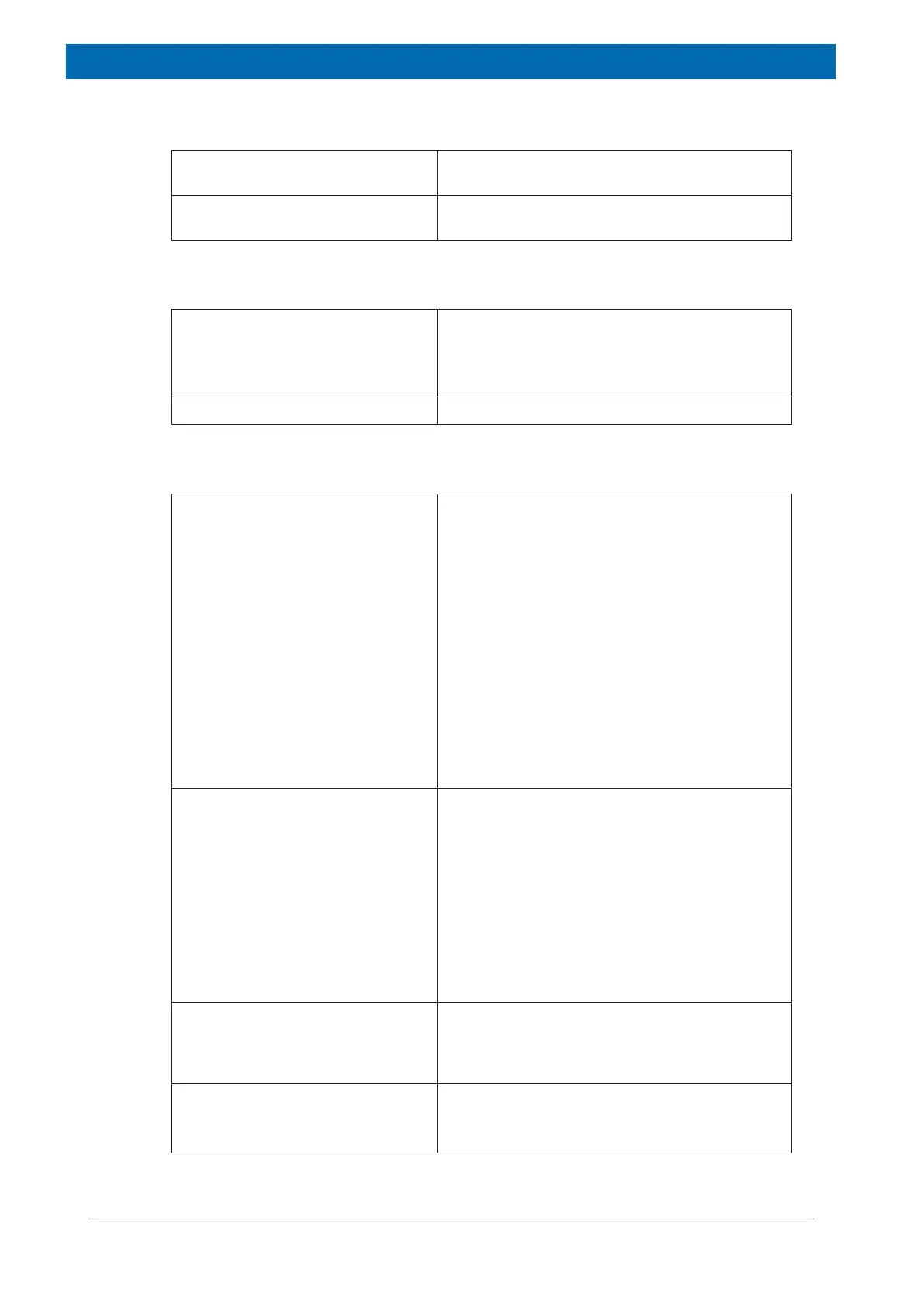

Gas Requirements

Case 1:

In-house N

2

gas supply used as the

main N

2

source.

Pressurized N

2

Gas:

• N

2

content: > 95% by volume

• Dew point: < -60°C @ 1 bar

• Pressure: 6-10 bar

• Oil content: < 0.005 ppm (0.00425 mg/m

3

)

• Solid impurities: Use 5 micron filters, filters

should retain 99.99% of the specified parti-

cles.

Capacity:

• Prodigy Unit: 40 l/min. (1.4 cfm) + VT gas: 11

l/min. (0.4 cfm).

• Sample protection option: Add 40 l/min. (1.4

cfm) to above values.

Case 2:

Compressed air with dew point <

-25°C available.

Use an N

2

gas separator to generate the required

N

2

gas on site (as specified in Case 1). Bruker of-

fers a N

2

Separator (P/N 46540). Requirements

for compressed air:

• Pressure: 7-10 bar.

• Oil content: < 0.005 ppm (0.00425 mg/m

3

)

• Solid impurities: Use 5 micron filters, filters

should retain 99.99% of the specified parti-

cles.

• Capacity: > 200 l/min. (7 cfm).

Case 3:

Compressed air with dew point >

-25°C available.

Use an additional air dryer in order to obtain com-

pressed air with a dew point < -25°C @ 1 bar (as

specified in Case 2 above). Bruker offers a mem-

brane dryer with 60 l/min., -80°C (P/N 1808577).

Backup N

2

Gas Supply

(optional; in addition to any of the

main gas supply variants above).

Independent N

2

gas source, e.g. a N

2

gas cylinder

fitted with a pressure reducing value.

Specifications: See Case 1 above.

Table10.7: Prodigy System N

2

Gas Requirements

Loading...

Loading...