Chapter 13

13-4

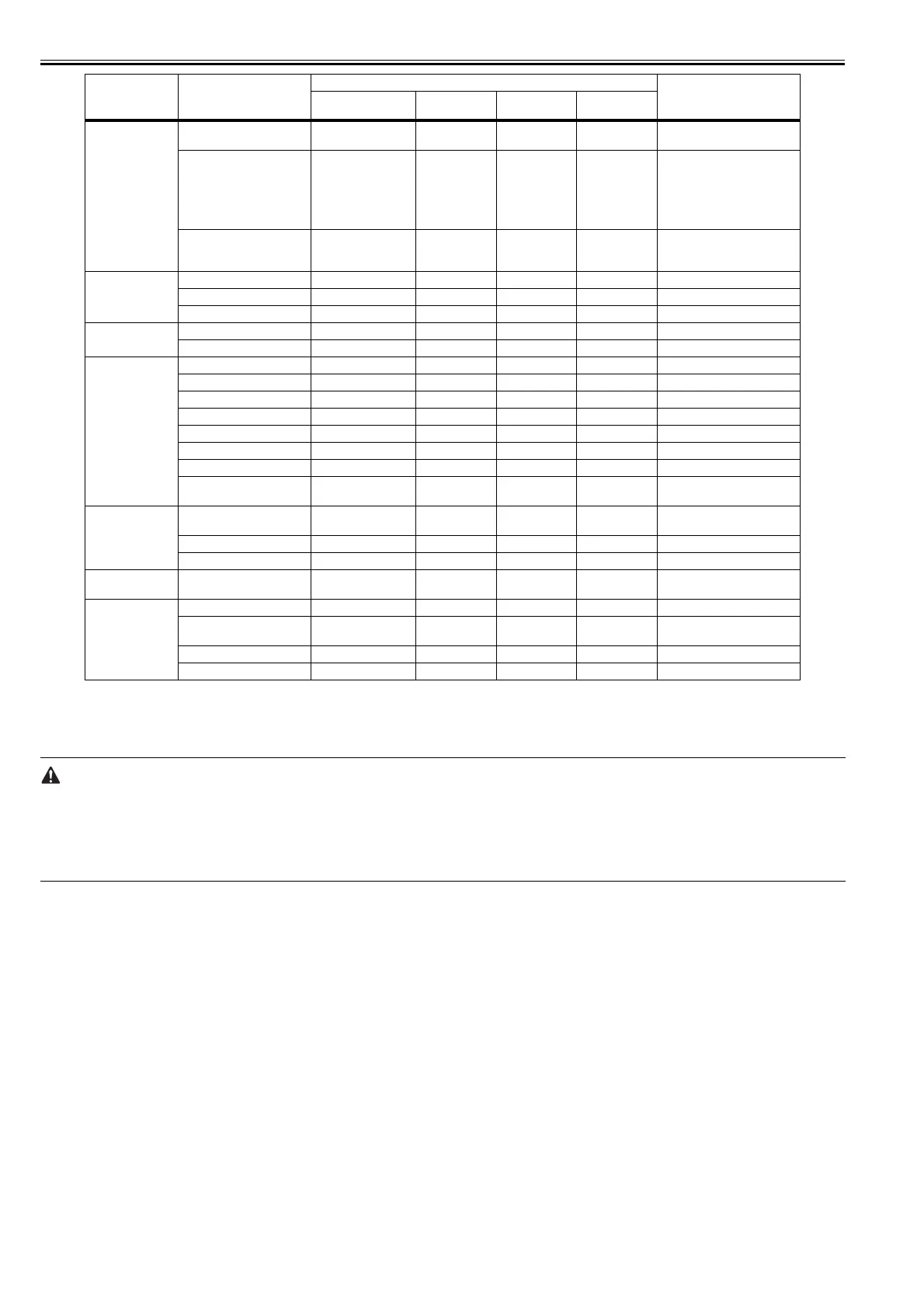

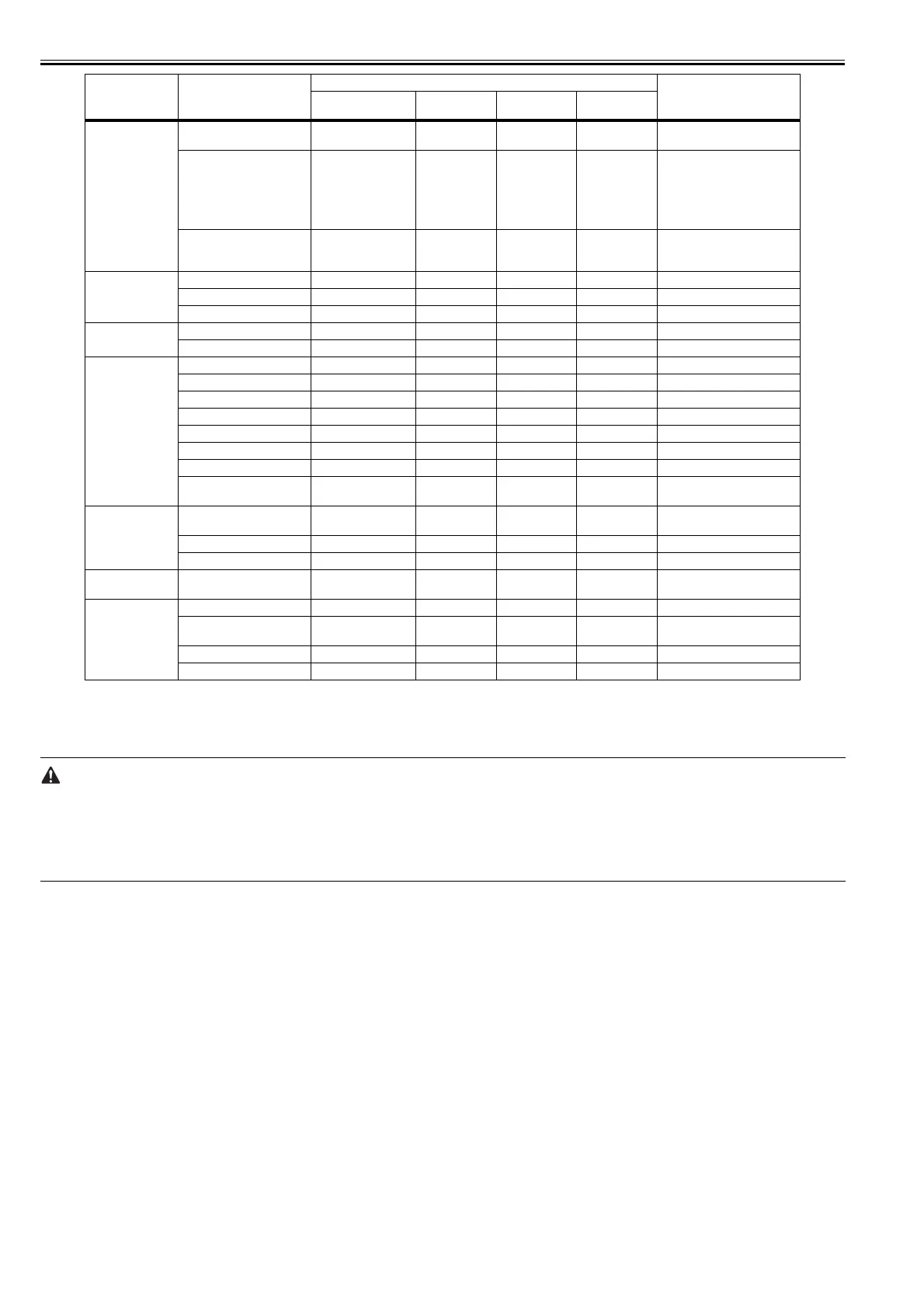

13.3.4 Points to Note for Periodical Servicing

0015-5273

iR5065 / iR 5055 / iR5075 / / /

Unless otherwise instructed, clean with lint-free paper and alcohol.

- Make a thorough check of the block (front, rear) for melting by leakage, deformation by heat, cracking, discoloration (yellowing). If a fault is found, replace the

part with a new one immediately.

- Check the block (front, rear) including its inside.

- Do not use a cloth on which metal powder is found.

- If you have used solvent, make sure that the part has dried completely before mounting it back to the machine.

- Do not use a moist cloth unless specifically indicated.

- Be sure to provide scheduled servicing/replacement at the specified intervals.

Photosensitive

drum

Photosensitive

drum

Clean Use alcohol and drum

cleaning powder (CK-0429).

Electrode (for slip ring of

drum heater)

Clean / Lubricate Clean with alcohol;

1) electrode,

2) protruding

wall of electrode (where FY9-

6008 is applied).

- Charge collecting brush

Drum separation claw Clean Replace In a high temperature and high

pressure environment, replaces

it by 250,000

Developing

assembly

Developing cylinder Inspect

Developing assembly roll Clean

Anti stray toner sheet Clean

Cleaner Side scraper Clean

collecting toner bottle holder Clean

Fixing

assembly

Inlet guide Clean

Web Inspect

Oil dish Clean

Web guide Clean

Thermistor unit Clean Replace

Sub thermistor Clean Replace

left stay Clean Both sides driving shaft

Static eliminator (pressure

roller)

Replace

Delivery

assembly

Separation claw (upper,

lower)

Clean

Internal delivery roll Clean

External delivery roll Clean

Toner collection

area

Collecting toner box Inspect Inspect case, and remove toner.

Pickup/ feeding

assembly

Transfer guide Clean

Registration

roller (upper, lower)

Clean

Feeding belt Clean

Feeding rollers Clean

Unit name Part

Intervals

Remarks

Upon

installation

every

250,000

every

500,000

every

1,000,000

Loading...

Loading...