Chapter 14

14-20

<Tolerance> +/-1 mm

[2] Pre-transfer charging wire

F-14-46

Height of the charging wire

<Tolerance> No height adjusting mechanism

[3] Transfer charging wire

F-14-47

Height of the charging wire

<Tolerance> +/-2 mm

[4] Separation charging wire

F-14-48

Height of the charging wire

<Tolerance> +/-2 mm

MEMO:

The height (position) of the primary charging wire and the transfer charging

wire can be adjusted by turning the screw at the back of the charging assem-

bly. A single turn changes the position of the charging wire by about 0.7 mm.

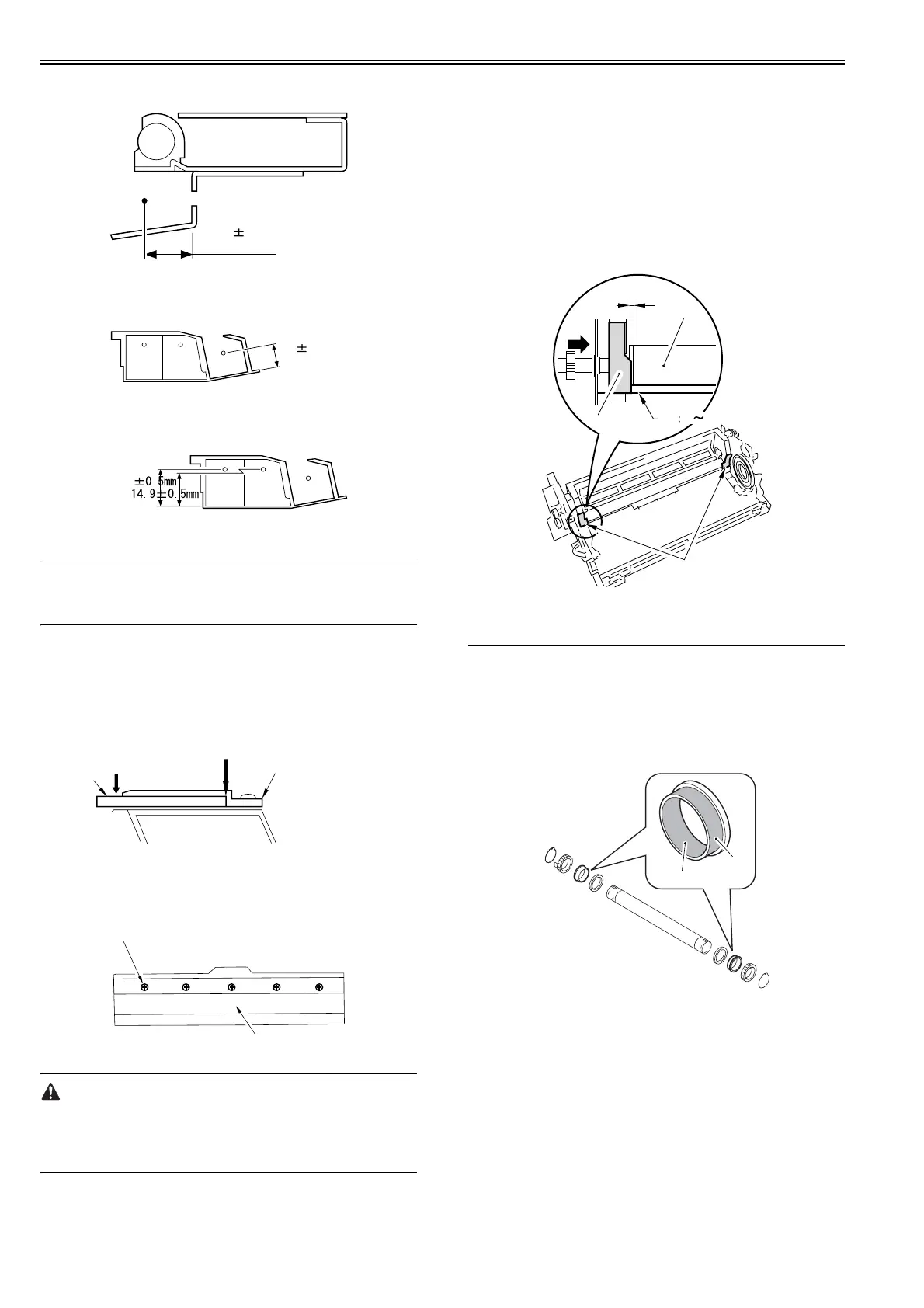

14.5.5 Mounting Cleaning Blade

0015-9970

iR5065 / iR 5055 / iR5075 / / /

When mounting the cleaning blade, be sure that the side with the marking [1]

will be the face.

1) Push in the cleaning blade [2] until it butts slightly against the rear.

F-14-49

2) Tighten the 5 screws [3] lightly, and stop to turn them when resistance is

felt.

3) Turn the screws tightened lightly in the step 2 about 20 to 30 degrees in

the order indicated below, and tighten them fully.

F-14-50

After mounting the cleaning blade, check that the edge of the blade is not ex-

tremely bent.

Further, be sure to clean the groove in the blade support plate before mount-

ing the blade, as toner or the like in the groove can be the cause the bending

of the blade. ÅB

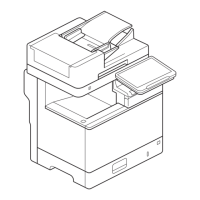

14.5.6 Removing Side Seal

0015-9972

iR5065 / iR 5055 / iR5075 / / /

1) Remove the old side seal.

2) Mount the new side seal [1] to the cleaner housing where indicated (both

ends).

At this time, be sure that the edge of the side seal is positioned as follow:

- When replacing the side seal [1] at the front, push the magnet roller [2]

toward the rear, and then, make sure that the inner end of the side seal is

within the area [3] of the washer.

- When replacing the side seal [1] at the rear, push the magnet roller [2]

toward the front, and then, make sure that the inner end of the side seal is

within the area [3] of the washer.

3) The bottom end of each side seal [1] must be 0 to 0.5 mm from the corner

of the cleaner housing; i.e., point of reference [4].

4) Attach the side seal [1] at the front and the rear to the cleaner housing

while making sure its position is as indicated.

F-14-51

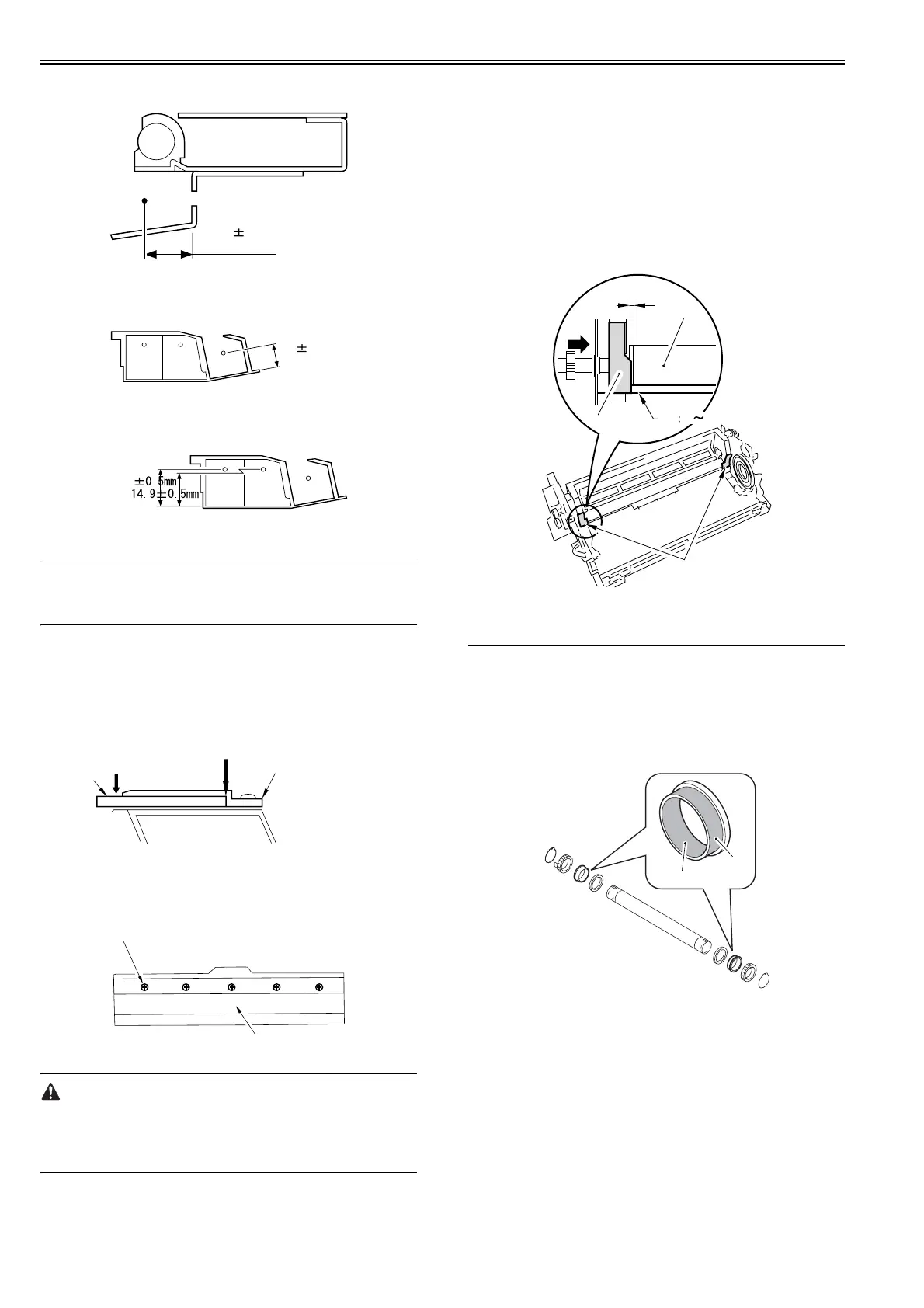

14.6 Fixing System

14.6.1 Applying Grease After Replacing the Fixing Roller

0015-9974

iR5065 / iR 5055 / iR5075 / / /

- About 20mg of grease (Molykote HP-300; CK-8012) should be applied

to the inner [1] and the outer surfaces [2] of the bushing until the white

coat covering is formed uniformly. If this undone, the noise (squeaking)

may occur.

F-14-52

- Applied grease may be transferred from the bushing to the fixing roller

ends [1] when mounting; be sure to wipe it off when this happens.

10.06 0.3 mm

9.5 0.5mm

6.0

No gap

Blade retaining plate

[2]

[1]

Order of tightening

5

[3]

3124

0 0.5mm

[3]

[2]

[1]

[4]

[1]

[2]

[1]

Loading...

Loading...