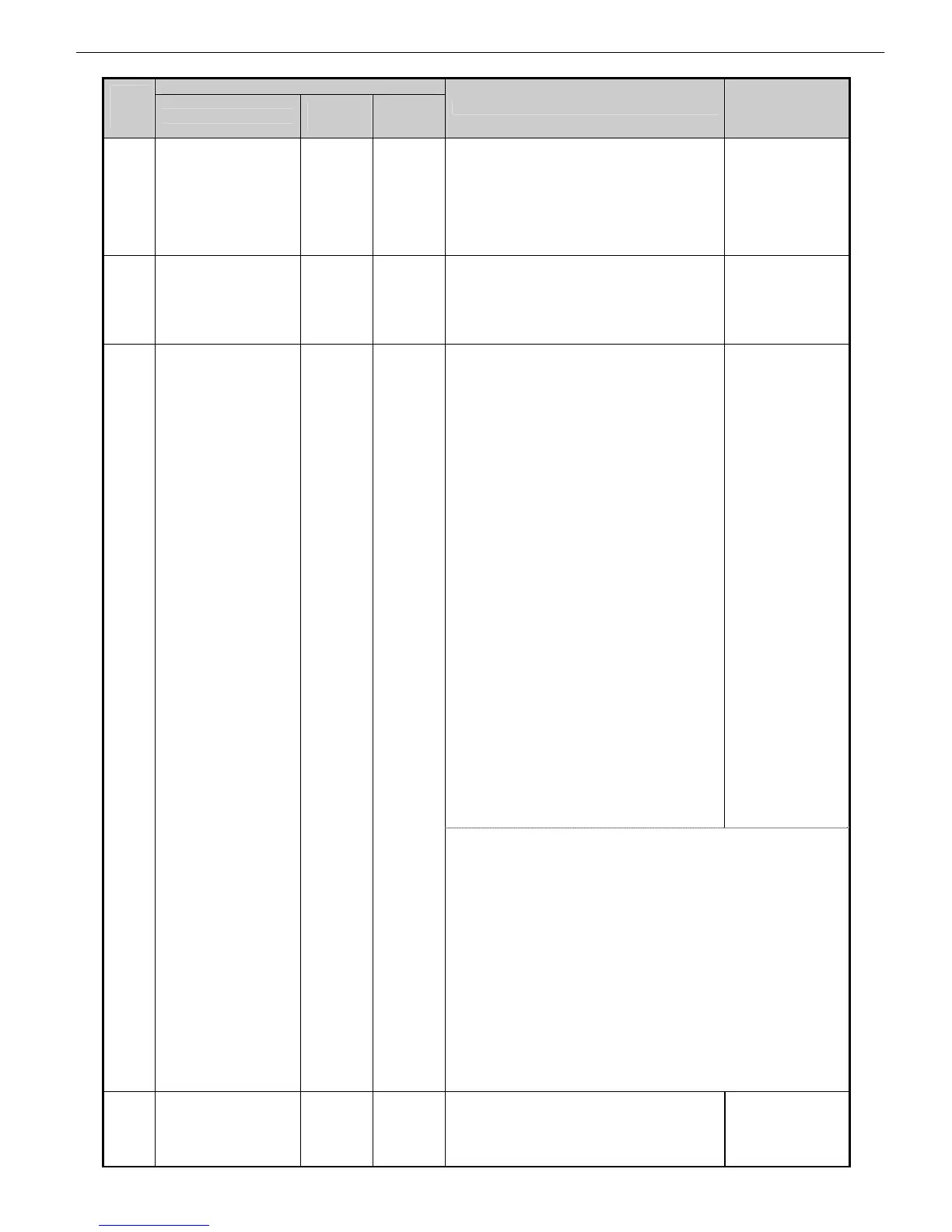

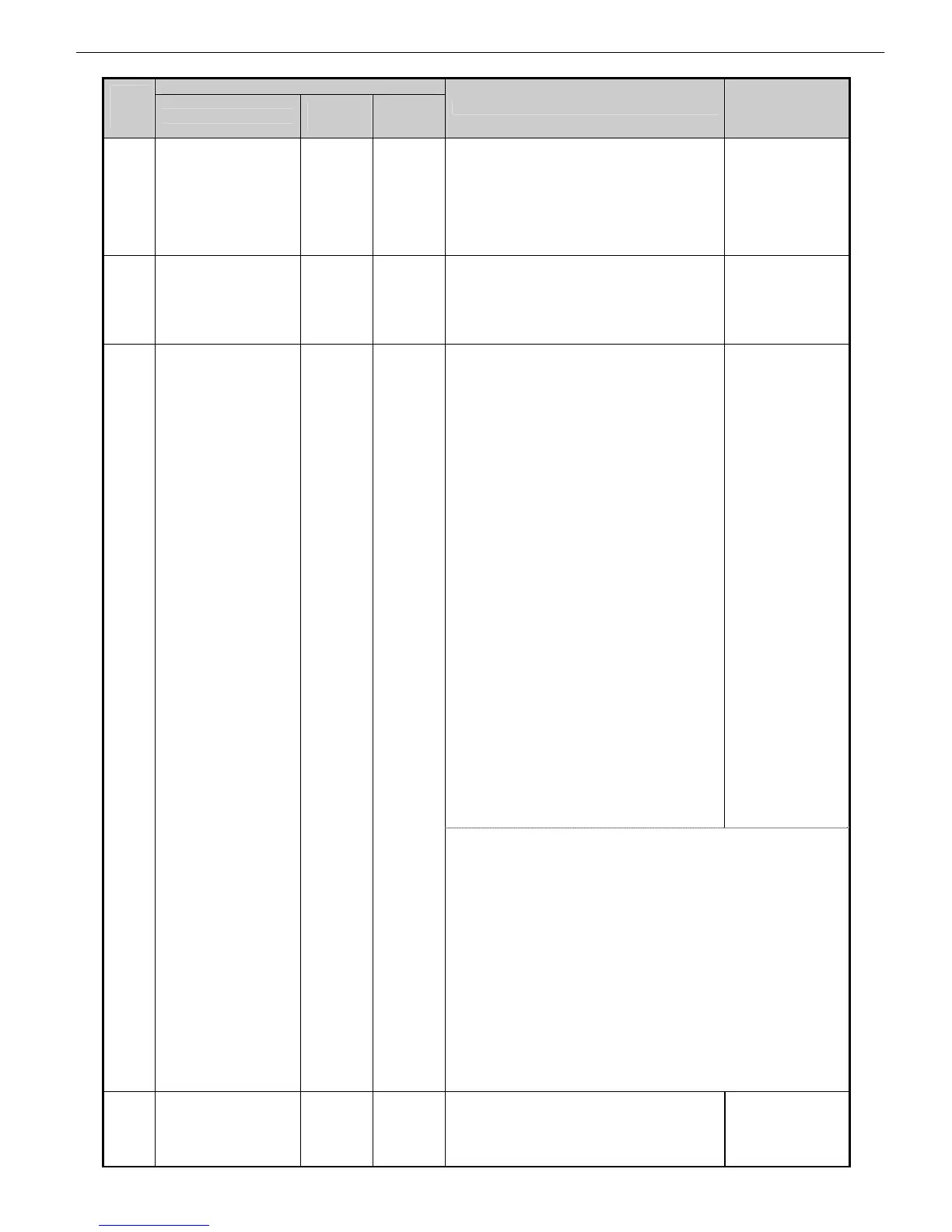

Chapter 2 Indexes by Case

2-47

Panel display

Code

(last 4

digits)

Large LCD

Small

LCD 1

Small

LCD 2

Explanation/Detection sequence

Remedial Action

(★: Reference fault

isolation procedure

or tool)

2F2D Cassette not

working.

Turn off printer,

wait, then

turn on again.

Power

On

Again

Cassette

Motion

Error

Cassette operation disabled

A PWM duty of 100% has lasted for 200

msec in a cassette operation.

①Check the

cassette motor

and the drive

circuit.

②Check the

cassette

encoder

sensor.

2F2E Hardware error.

03130031-2F2E

Turn off printer,

wait, then

turn on again.

Power

On

Again

Roll

Motion

Timeout

Roll shift timeout

No sensor has been detected during a roll

operation involving sensor detection.

Go to ★200C

(P3-8).

Non-ejection detection error

As a result of nozzle checking made by the

head management sensor unit:

①All 640 nozzles in a nozzle line are

non-discharging.

② At least 50 nozzles have been found

mismatched in a nozzle line of 640 nozzles

since the last session of detection.

①Check whether

any foreign

matter such as

paper slip

exists on the

head

management

sensor optical

axis.

②Light

interception

due to ink

accumulation.

⇒Remove the

ink/ Replace

the unit.

③Check the

head

management

sensor’s

connector

connection

④If Service

mode nozzle

check pattern

printing is no

problem,

replace the

head

management

sensor unit.

Go to ★2F2F

(P3-6).

2F2F Hardware error.

03800500-2F2F

Turn off printer,

wait, then

turn on again.

Power

On

Again

Eject.

Detect

Err

Reference 1) As for the detection condition ① above, in the

iPF650/750, iPF6300/6350, and iPF8300 series or later, the error

codes are broken up into 2F40,2F41,2F42,2F43,2F44, and 2F47

depending on the non-ejection conditions.

Reference 2) Error 2F2F,2F40,2F41,2F42,2F43,2F44, and 2F47

are detected in the following order.

①Determines signal level (2F47) of head management sensor

②Determines complete non-ejection of all colors (2F40)

③Determines multiple mismatches (2F2F)

④Determines complete non-ejection of a single color (2F41)

⑤Determines complete non-ejection of one line (2F42)

⑥Determines complete non-ejection of 640 nozzles (2F43)

⑦Determines non-ejection of more than 320 nozzles (2F44)

Reference 3) The amount of change (between non-ejecting and

ejecting nozzle counts) from the last session of nozzle checking is

defined as the amount of mismatch.

2F30 Hardware error.

xxxxxxxx-xxxx

Turn off printer,

wait, then

turn on again.

Non-ejection detecting position error

No detectable region has been found during

non-ejection position adjustment.

Go to ★2F2F

(P3-6).

Loading...

Loading...