Chapter 4 More Sophisticated Fault Isolation Tasks

3-21

Cause Point to check Action

C1 With the cover open, check to see if jams have not occurred. Remove.

C1 Check the firmware version (Paper jam detection)

Update to the

latest version

C4 Check that ink is available in the ink tube. 2F2F (P3-6)

C1

Check to see if a paper cutting failure has not occurred on the most recently used

printed matter.

2015 (P3-17)

C1 Check the face of the printhead (to see if it is not flawed by paper or foreign matter). Replace the head.

C2,C3

After removing and inserting the print head, start in service mode to clear the error.

Then, restart the printer in normal mode to check to see if the error recurs (possibly

poor contact).

Replace the head.

C5 Check the main unit electrical equipment. Flow 1

13. 【403E】,【403F】Printhead abnormal temperature

rises

Occurrence

condition

Three instances of the internal head temperature sensor reaching 120

o

C or higher (or -10

o

C or

lower) have been detected for 28 ms.

C1

The face is physically damaged from jammed paper or from foreign matter falling

onto the platen.

C2

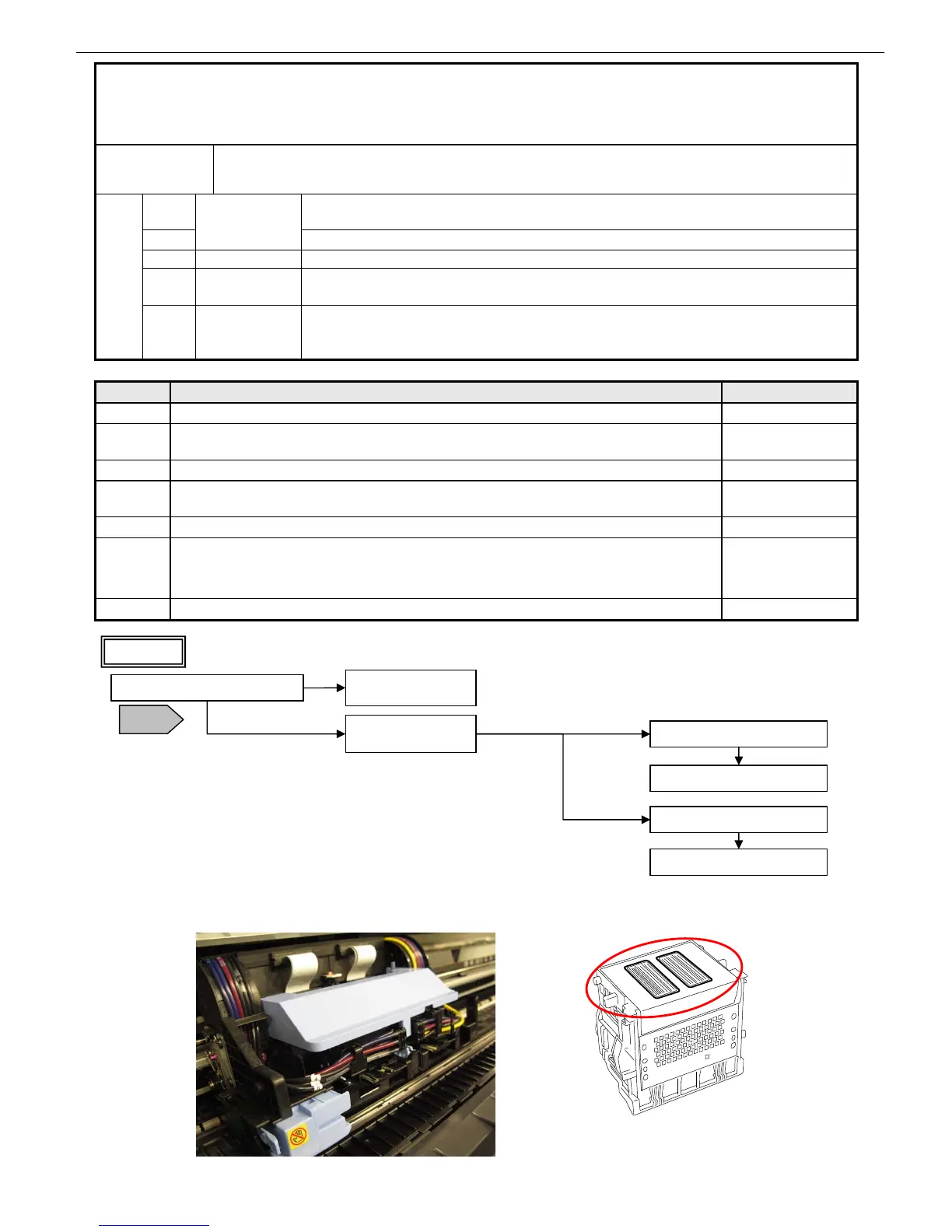

Printhead

Electrical shorting in the head

C3 Electrical Poor head contact

C4

Ink supply

system

Abnormal head temperature rises caused by non-discharging

Failure causes

C5

Main unit

electrical

equipment

Faulty carriage (relay) PCB, head relay PCB, flexible cable, main controller

Check the face for flaws

(never touch the face)

Check the ink in the tube

Is the flexible cable broken?

Replace the flexible

cable

Replace the carriage relay PCB

Replace the main

controller

Yes

No

Replace the carriage PCB

Replace the head relay PCB

iPF5000/iPF800 Series

iPF700/iPF8000 Series

Replace the carriage unit

Flow 1

T18

Loading...

Loading...