Troubleshooting Guide

3-18

Cause Point to check Action

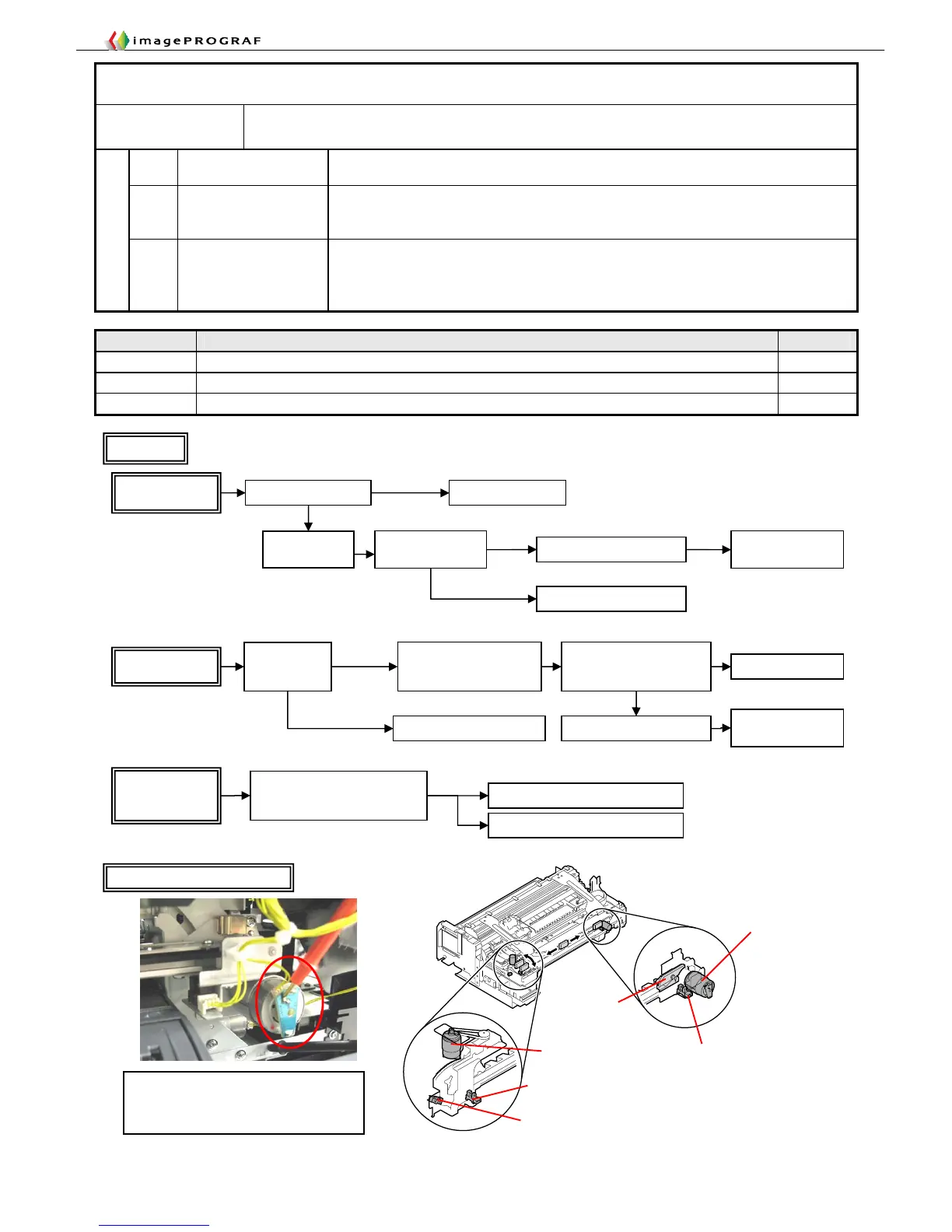

C1, C2, C3 Check the cutter position at an error stop.

C1, C2, C3 iPF5000/iPF800 Series Flow 1

C1, C2, C3 iPF700/iPF8000 Series Flow 2

11. 【2F24】Cutter shift timeout error

Occurrence

condition

The cutter wont’ move to the home position or the position opposite to the home position in

time.

C1 Cannot cut sheet

Worn cutter

Special paper

C2

Faulty cutter drive

unit

Worn/broken drive gear (iPF5000 Series)

Faulty cutter motor (iPF5000 Series)

Carriage malfunction (iPF700, iPF8000 Series)

Failure causes

C3

Faulty cutter

electrical equipment

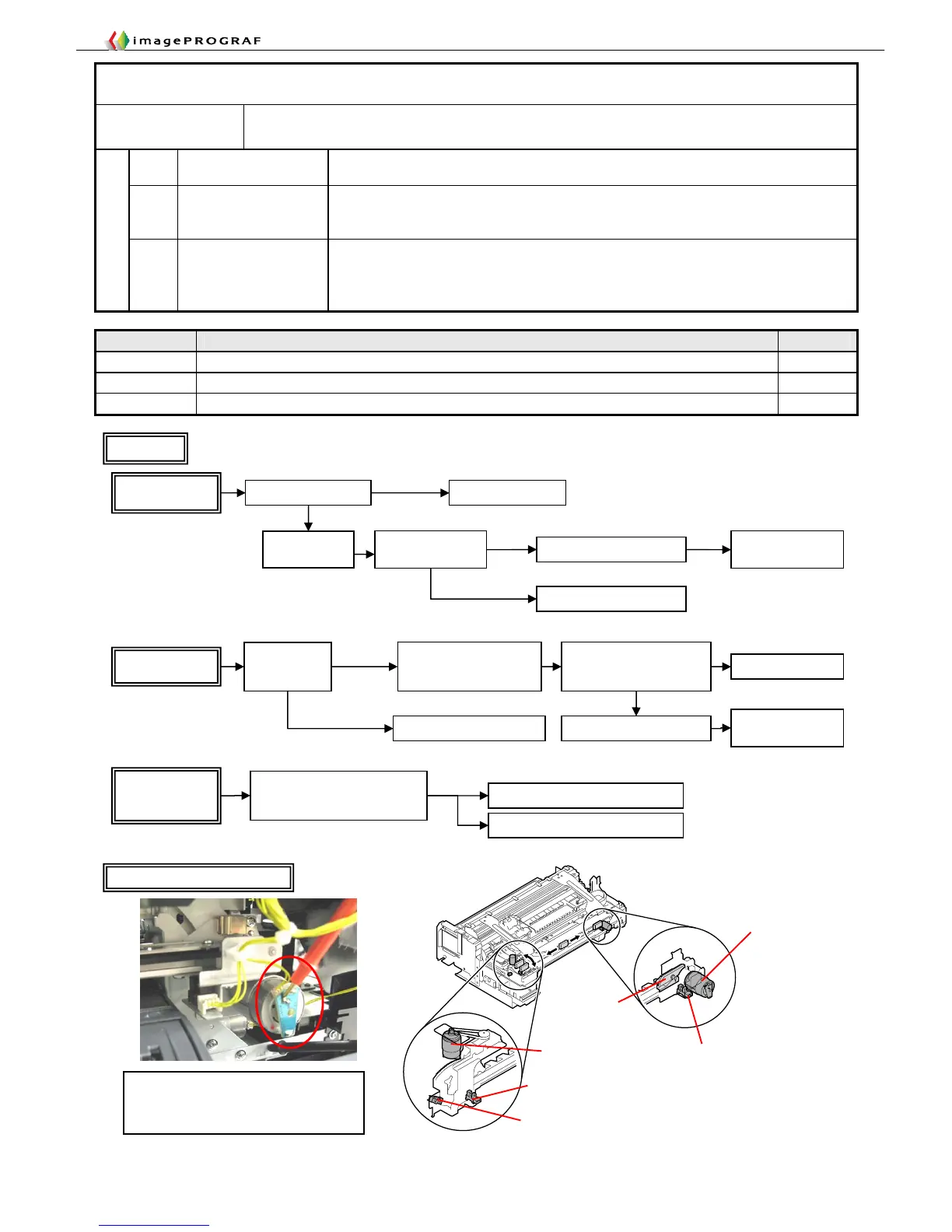

Bitten wires (iPF5000 Series)

Faulty sensor

Faulty cutter driver PCB (iPF5000, iPF500, iPF600 only)

Faulty main controller (iPF5000 Series)

Cutter Motor Drive Volta

e Check

Evaluation method

The drive voltage is normal if the voltage

appears to vary by a margin of several volts

while the cutter is driven.

Cutter moto

Cutter positioned

at the left end

iPF5000/iPF800 Series

Cutter positioned

at the right end

Cutter anywhere

other than the left

and right ends

Check the

right-side

sensor visually

Remove the foreign matter

Foreign matter

present

No foreign

matter

A sensor fault has been

identified by replacing with

a lift detection sensor

Replace the cuter driver

Replace the sensor

For the iPF5000, iPF500 and iPF600 onl

Replace the main

controller

-Check for bitten wires

-Check for successful

operation in IO mode

Is the motor rotating?

Yes

Check the gear/belt

No

Replace the cutter driver

For the iPF5000, iPF500 and

iPF600 only

Replace the main

controller

Replace the motor

Is the drive voltage

available (*) ?

*See “Cutter Motor Drive Voltage Check” for the subsequent action to take.

Remove foreign matter

from the sensor if any

Check for bitten

wires

Yes

No

Replace the cutter

If non-recommended paper has

been used, check with a

recommended paper equivalent

Replace with recommended paper

Flow 1

Loading...

Loading...