Troubleshooting Guide

3-14

Cause Key point to check Action

C2

If roll paper are being fed, check the roll paper unit for operation (pendulum gear).

If a jam occurs while loading cut sheet (fed from the top) or rewinding roll paper with the

feeding methods switched, the roll paper unit is at operational fault.

Fix.

C1 Improper LF belt tension, faulty LF motor or faulty LF encoder Check.

C2 Check to see if there is any jam on the paper ejection side of the LF_PE sensor. Check.

C3 Check the cutter drive unit. Flow 1

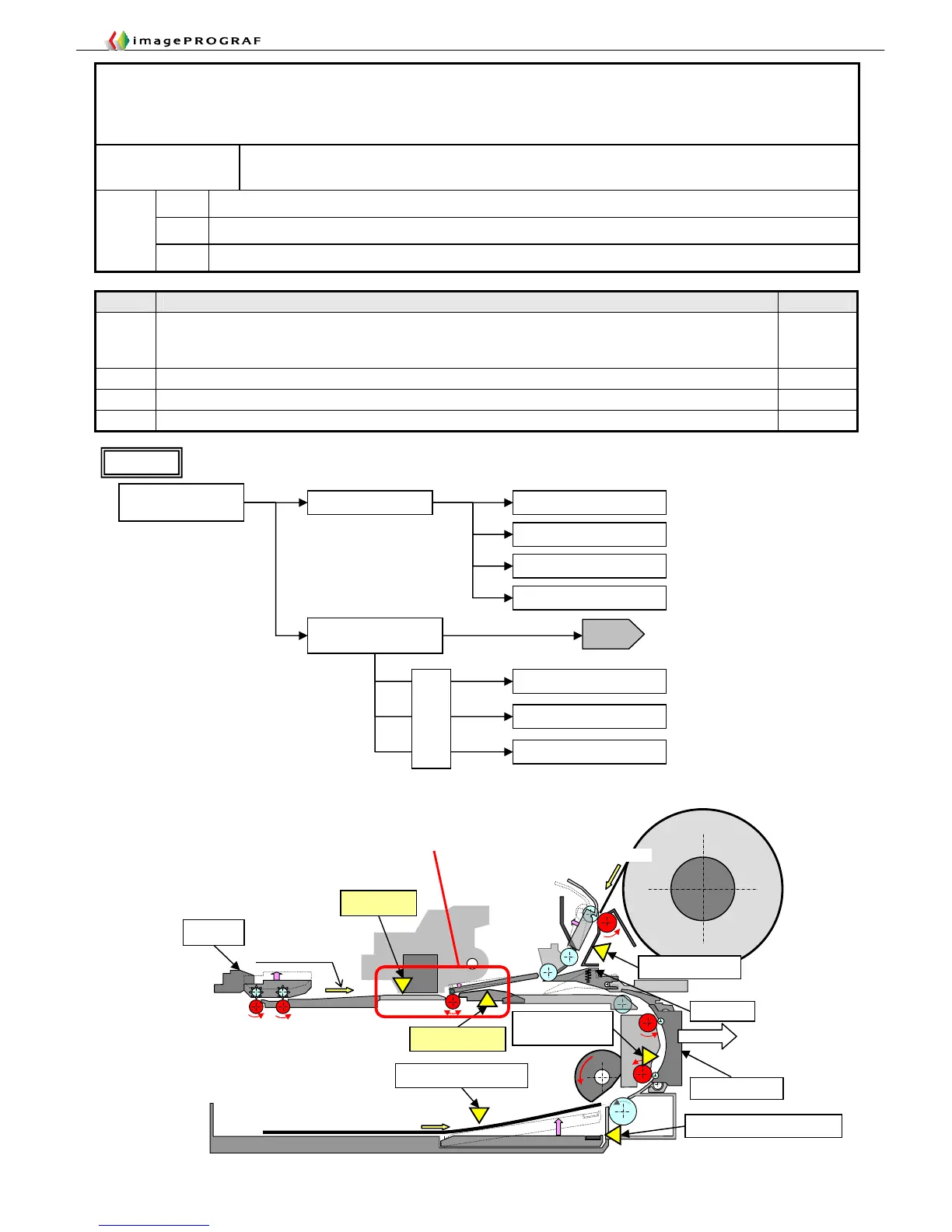

7. 【2E27】Paper jam while feeding, ejecting or printing on

paper (Jam 1)

Occurrence

conditions

Jams occurring between the LF_PE sensor and the multisensor

C1 LF out of synchronization

C2 Jams past the LF_PE sensor

Failure

causes

C3 Faulty cutter drive unit (iPF5000 Series only)

Prefed paper

detection sensor

Paper detection sensor

LF_PE sensor

Roll feed senso

Back cover

Manual feeding from

top (POP board)

Cassette detection sensor

Jam occurring in the path of paper travel between

the LF_PE sensor and the multisensor

■iPF500 Series

S

S

S

S

S

S

Feeding of roll

media fed from top

Feed paper manually and

perform Forced Cut

2F26

Fault isolation for malfunctioning (iPF5000 Series only)

Cutter idle

Check the lift motor for

operation

Does the cutter lift on

switching from roll

media to cut media?

Cutter driven

Not lifting

Replace the lifter motor

Lifting

Replace the cutter motor

Replace the cutter driver PCB

Replace the cutter motor

Check for bitten wires

Replace the cutter driver PCB

Replace the main controller

Replace the main controller

iPF5000, iPF500, iPF600 only

Check for bitten

wires

Flow 1

Carriage inoperable

iPF5000, iPF500, iPF600 only

Loading...

Loading...