CHAPTER 6 - MAINTENANCE AND ADJUSTMENTS

6-5

6-34551NA Issued 8-04 Bur

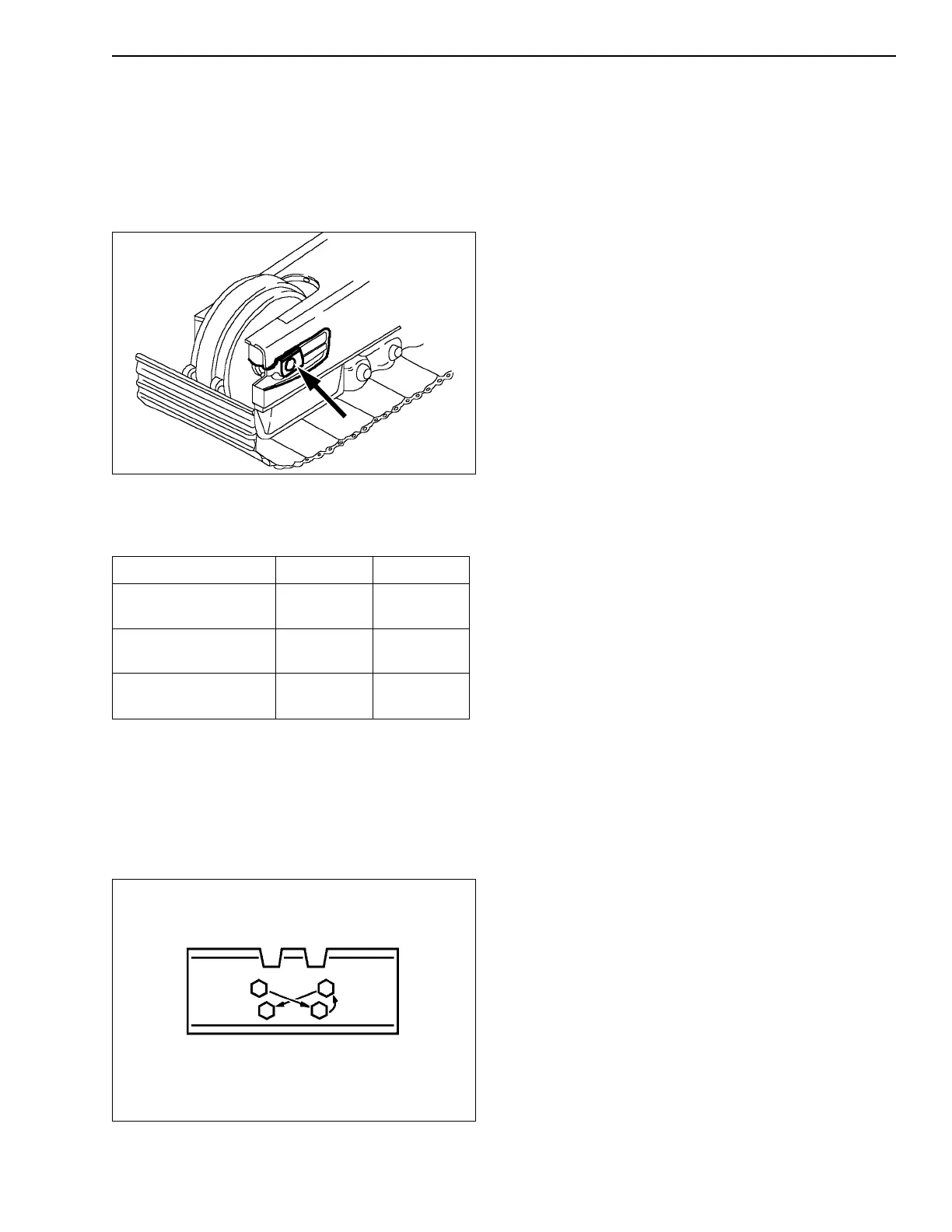

3. Clean the grease adaptor and fitting and then

lower the raised track to the ground.

4. Repeat Steps 1 to 3 for the other track.

IMPORTANT: If the grease fitting adaptor is

damaged, grease may leak out. Check the condition

of the grease fitting adaptor regularly and replace it if

necessary.

CT02D178

Figure 8

TRACK TENSION VALUE

The value (A) should be between:

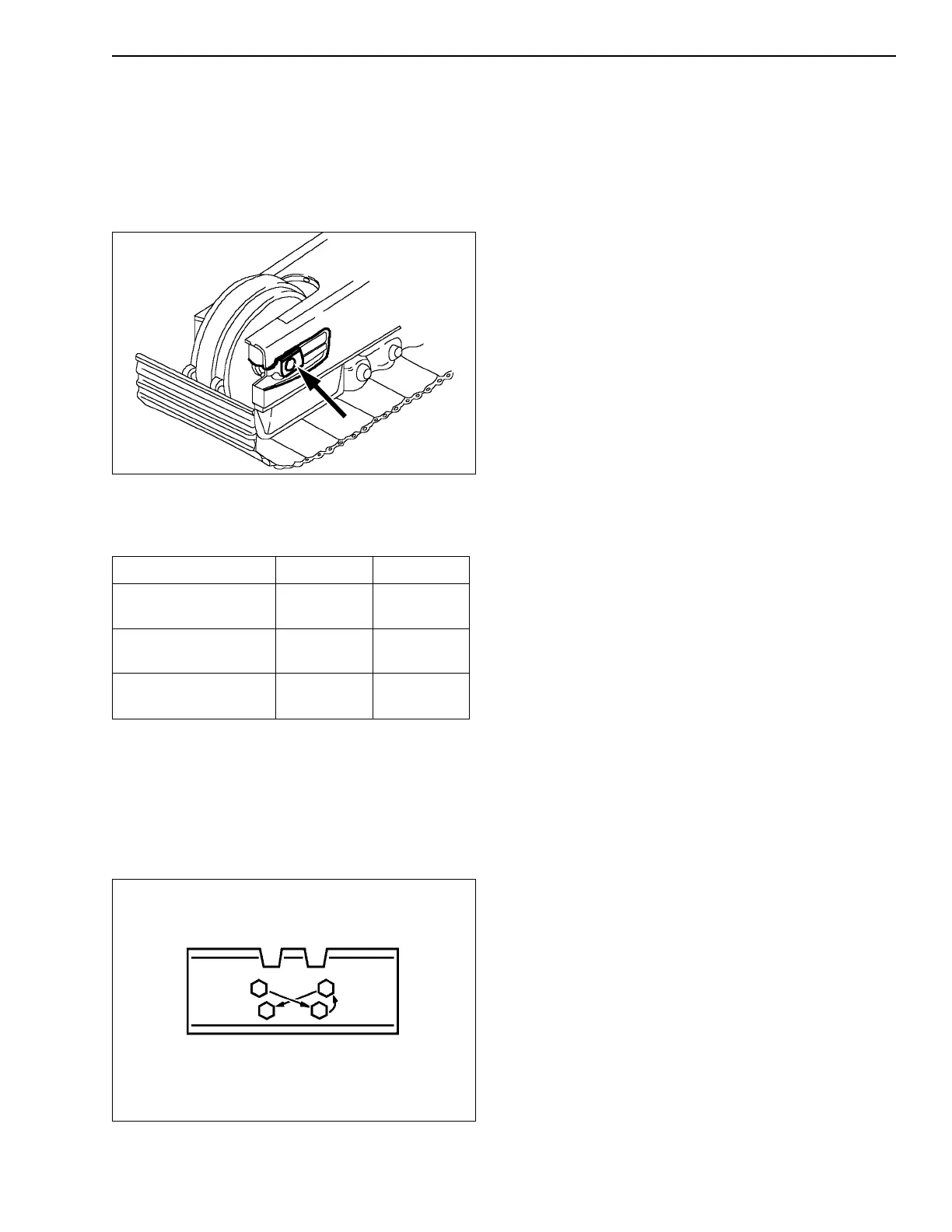

TIGHTENING TORQUE OF THE TRACK SHOE

The tightening torque of the bolts should be between:

CX75SR, CX80 = 220 to 270 Nm (162 to 199 ft. lb.)

CX135SR = 390 to 430 Nm (287 to 317 ft. lb.)

Follow the prescribed order.

CS00E504

Figure 9

Machines CX75SR, CX80 CX135SR

Rubber tracks

125 - 135 mm

(4.9 - 5.3 in)

Steel tracks

180 - 205 mm

(7.0 - 8.0 in)

240 - 269 mm

(9.4 - 10.5 in)

Rubber tracks and

steel chains

160 - 185 mm

(6.2 - 7.2 in)

Loading...

Loading...