CHAPTER 6 - MAINTENANCE AND ADJUSTMENTS

6-18

Issued 8-04 Bur 6-34551NA

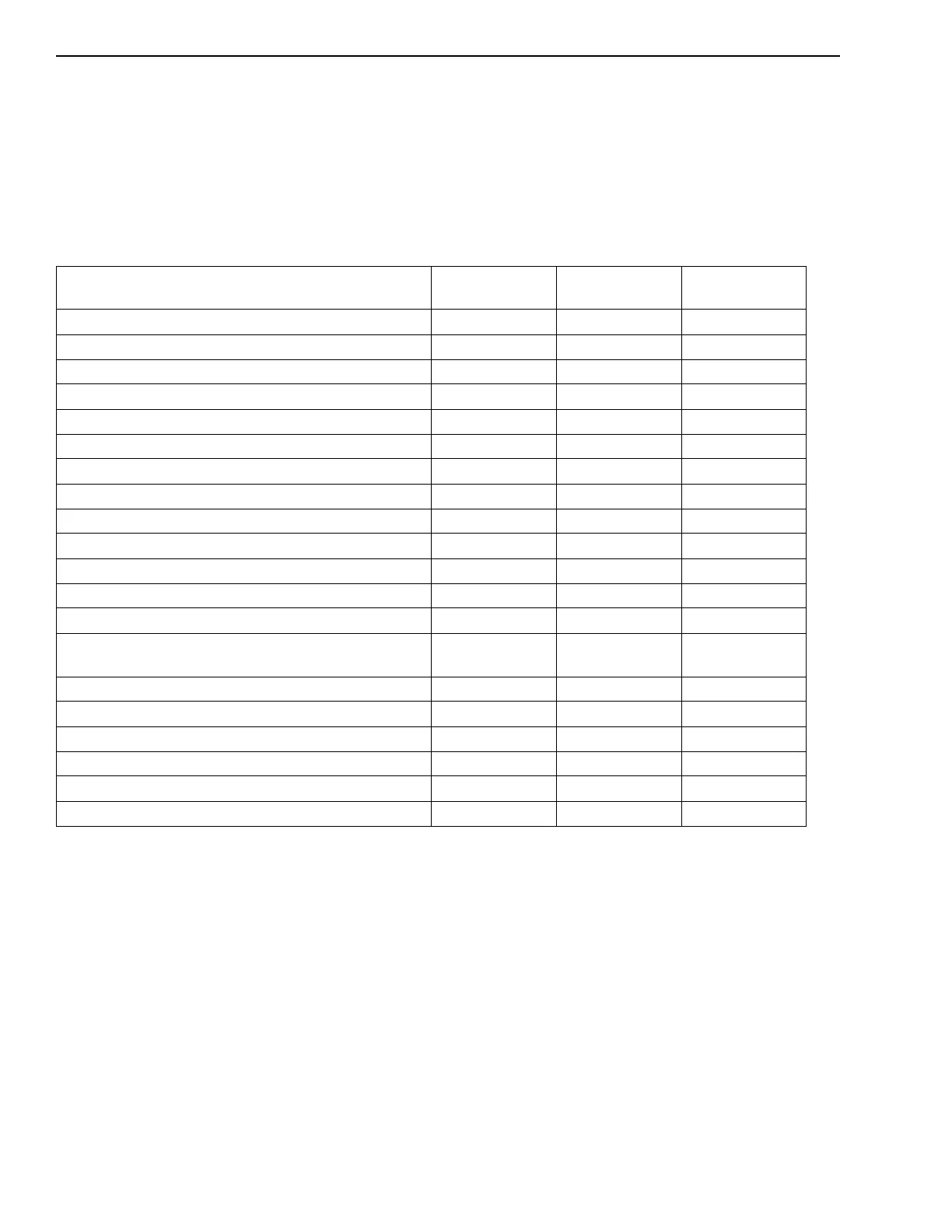

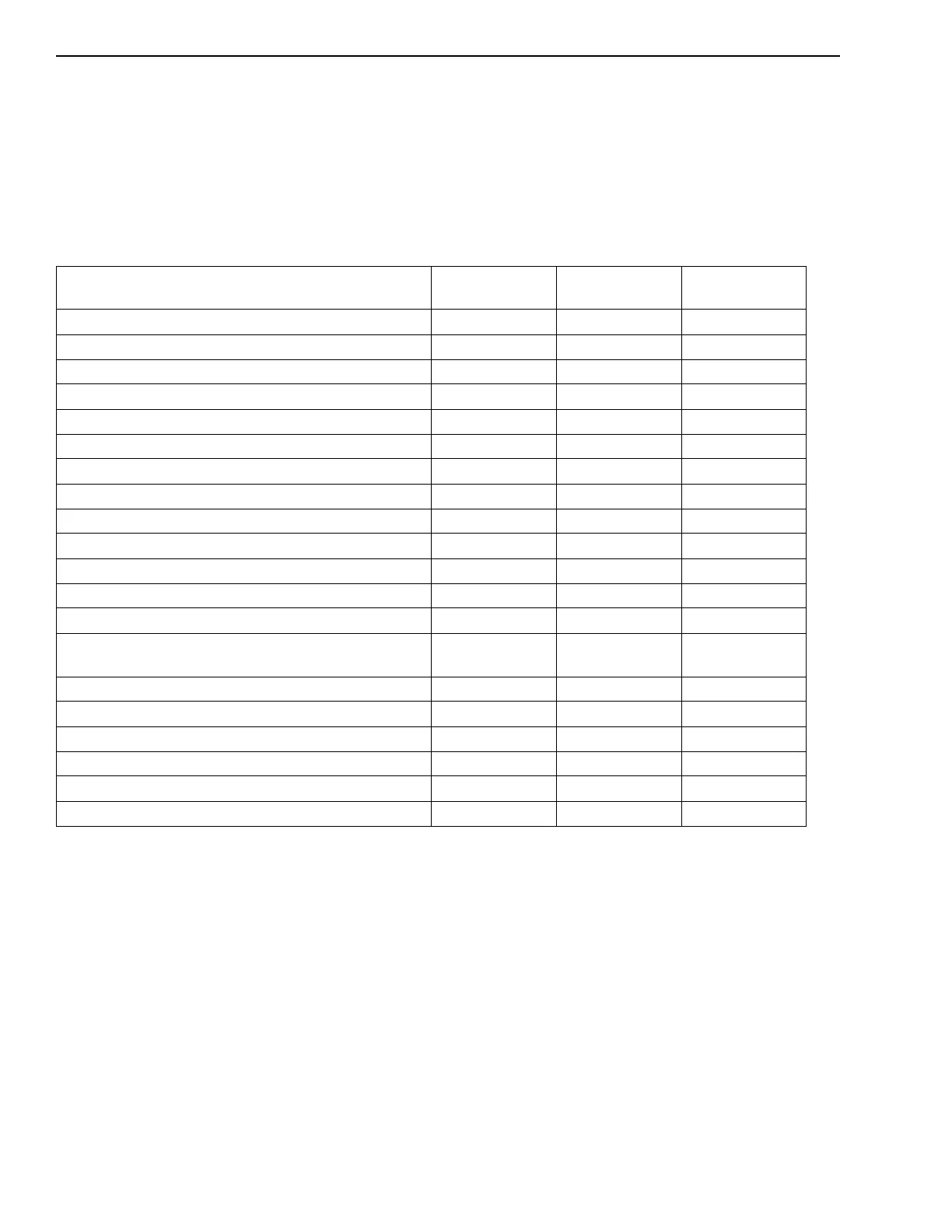

HARDWARE TORQUE INSPECTION

MAINTENANCE SPECIFICATION

Check ................................................................................................................................................Every 250 hours

(after the first 50 hours during the run-in period)

At the end of each working day, check all mounting nuts and screws for tightness and tighten if necessary. Make

sure no hardware items are missing. Replace them, if necessary.

(CX75SR, CX80)

NOTE: Use Loctite 262, or the equivalent, on screws marked (*).

Component

Screw

(Ø)

Wrench

(mm)

Torque setting

(Nm)

Travel reduction gear (*) M16 24 267-312

Drive sprocket (*) M14 22 173-202

Idler wheel (*) M10 17 62-73

Upper roller (*) M16 24 267-312

Lower roller (*) M20 30 521-608

Track shoe M16 24 220-270

Counterweight M14 22 220-270

Turntable (undercarriage) M24 36 850-992

Turntable (upperstructure) M16 24 252-283

Swing reduction gear (*) M16 24 273-317

Engine (*) M16 24 265-313

Engine mounts (*) M10 17 64-74

Radiator M10 17 64-74

Hydraulic pump (*)

M10

M12

17

Male

63-73

109-126

Hydraulic reservoir (*) M12 19 69-78

Fuel tank (*) M10 17 36-44

Control valve (*) M12 19 53-64

Hydraulic swivel (*) M10 17 63-73

Cab M16 24 78-80

Batteries M10 17 20-29

Loading...

Loading...