STANDARD PROCEDURE

STANDARD PROCEDURE - PISTON TO

CYLINDER BORE FITTING

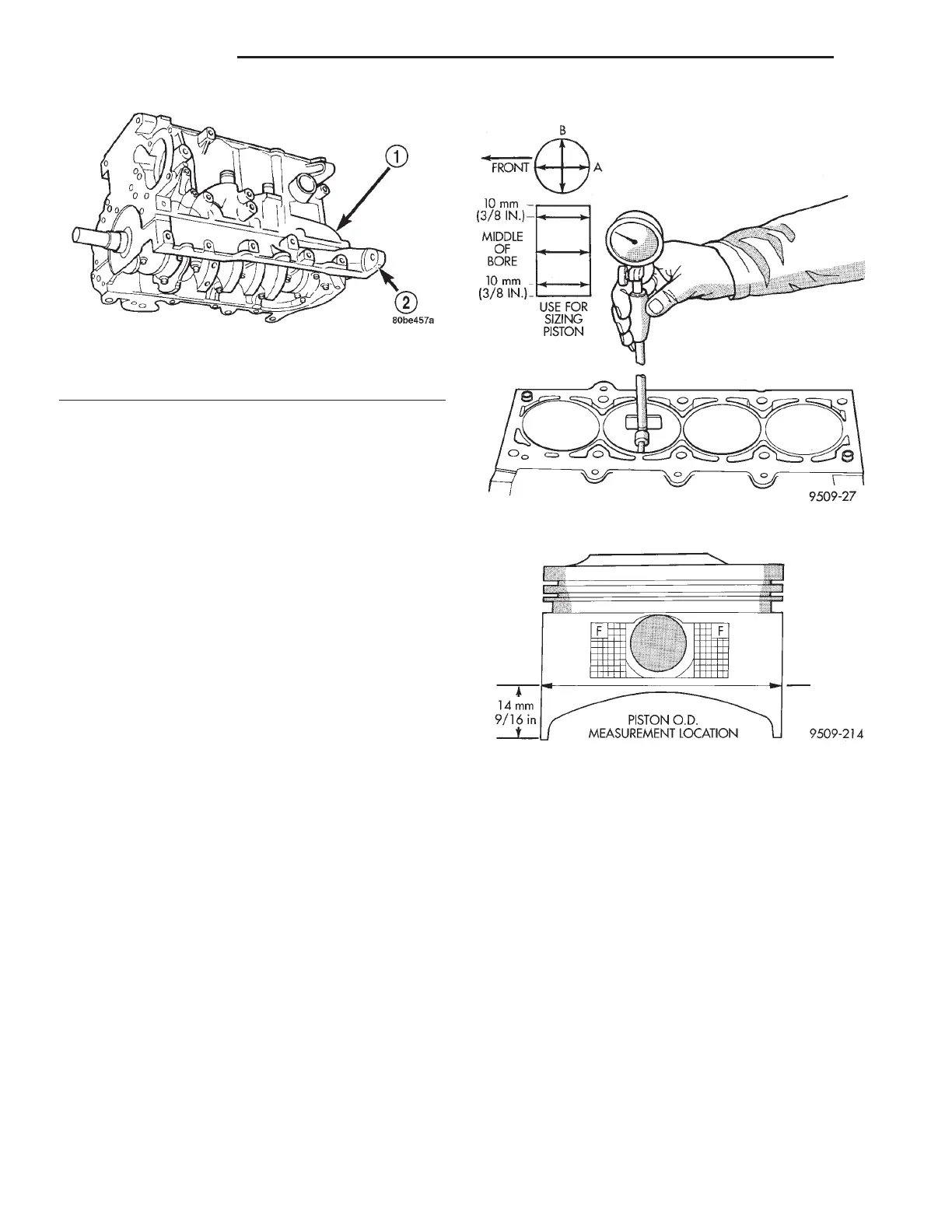

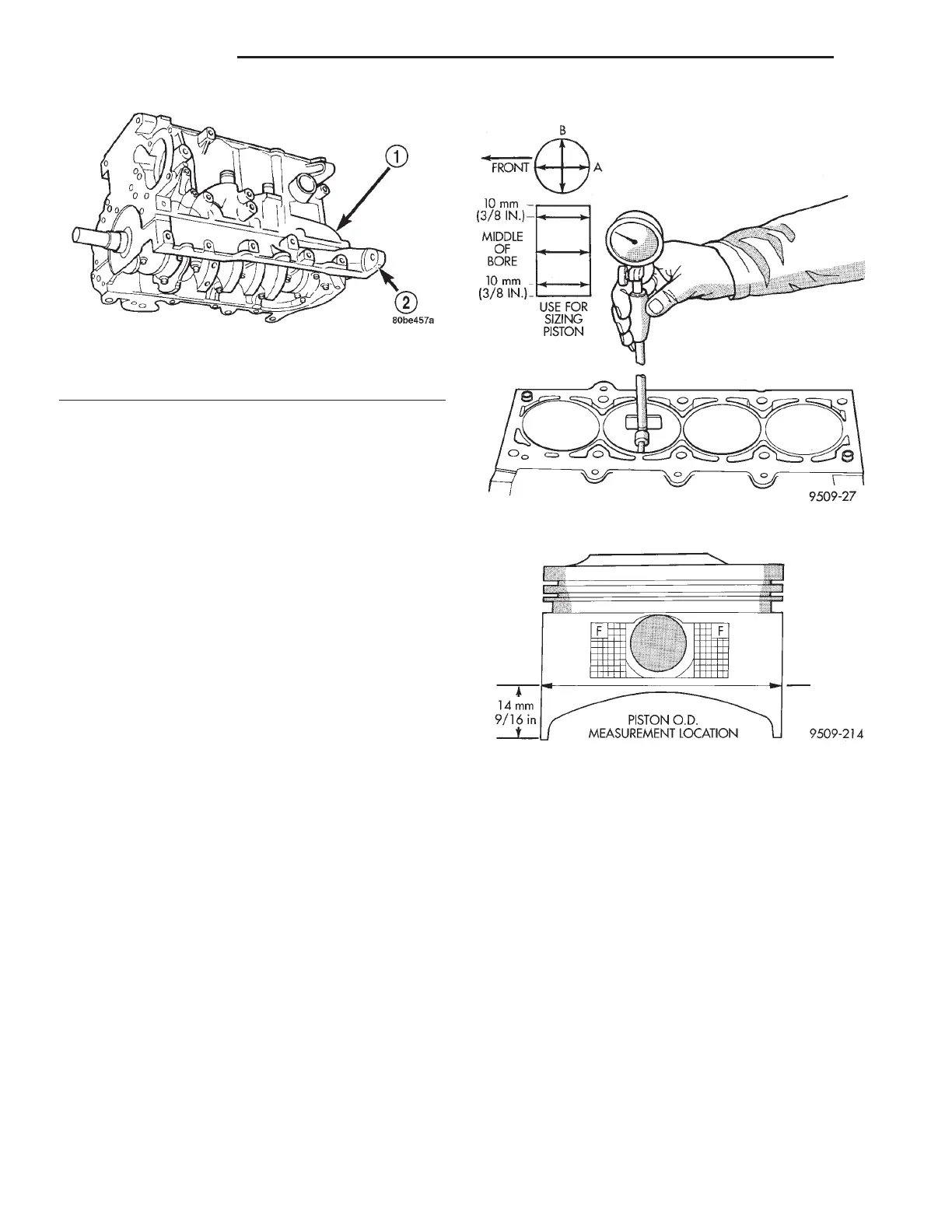

Piston and cylinder wall must be clean and dry.

Piston diameter should be measured 90 degrees to

piston pin about 14 mm (9/16 inch.) from the bottom

of the skirt as shown in (Fig. 42). Cylinder bores

should be measured halfway down the cylinder bore

and transverse to the engine crankshaft center line

shown in (Fig. 41). Refer to for Engine Specifications

(Refer to 9 - ENGINE - SPECIFICATIONS). Correct

piston to bore clearance must be established in order

to assure quiet and economical operation.

NOTE: Pistons and cylinder bores should be mea-

sured at normal room temperature, 21°C (70°F).

STANDARD PROCEDURE - CYLINDER BORE

HONING

(1) Used carefully, the cylinder bore resizing hone,

recommended tool C-823 or equivalent, equipped

with 220 grit stones, is the best tool for this honing

procedure. In addition to deglazing, it will reduce

taper and out-of-round as well as removing light

scuffing, scoring or scratches. Usually a few strokes

will clean up a bore and maintain the required lim-

its.

(2) Deglazing of the cylinder walls may be done

using a cylinder surfacing hone, recommended tool

C-3501 or equivalent, equipped with 280 grit stones,

if the cylinder bore is straight and round. 20–60

strokes depending on the bore condition, will be suf-

ficient to provide a satisfactory surface. Use a light

honing oil. Do not use engine or transmission oil,

mineral spirits or kerosene. Inspect cylinder walls

after each 20 strokes.

(3) Honing should be done by moving the hone up

and down fast enough to get a cross-hatch pattern.

When hone marks intersect at 40-60 degrees, the

cross hatch angle is most satisfactory for proper seat-

ing of rings (Fig. 43).

(4) A controlled hone motor speed between

200–300 RPM is necessary to obtain the proper cross-

hatch angle. The number of up and down strokes per

minute can be regulated to get the desired 40–60

degree angle. Faster up and down strokes increase

the cross-hatch angle.

(5) After honing, it is necessary that the block be

cleaned again to remove all traces of abrasive.

Fig. 40 Cylinder Block and Bedplate

1 - CYLINDER BLOCK

2 - BEDPLATE

Fig. 41 Checking Cylinder Bore

Fig. 42 Piston Measurement

9 - 36 ENGINE 2.4L RS

ENGINE BLOCK (Continued)

Loading...

Loading...