COOLING

TABLE OF CONTENTS

page page

COOLING

DESCRIPTION

DESCRIPTION - COOLING SYSTEM ........1

DESCRIPTION - HOSE CLAMPS ...........1

OPERATION

OPERATION - COOLING SYSTEM .........2

OPERATION - HOSE CLAMPS ............2

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - COOLING

SYSTEM LEAK TEST....................2

DIAGNOSIS AND TESTING - COOLING

SYSTEM FLOW CHECK .................3

DIAGNOSIS AND TESTING - COOLING

SYSTEM AERATION ....................4

DIAGNOSIS AND TESTING - COOLING

SYSTEM DEAERATION ..................4

STANDARD PROCEDURE

STANDARD PROCEDURE - COOLING

SYSTEM DRAINING ....................4

STANDARD PROCEDURE - COOLING

SYSTEM FILLING ......................4

STANDARD PROCEDURE - ADDING

ADDITIONAL COOLANT .................4

STANDARD PROCEDURE - COOLANT

LEVEL CHECK ........................5

SPECIFICATIONS

COOLING SYSTEM CAPACITY ............6

ACCESSORY DRIVE BELT TENSION .......6

TORQUE .............................6

SPECIAL TOOLS

COOLING SYSTEM .....................7

ACCESSORY DRIVE .......................8

ENGINE ...............................14

TRANSMISSION .........................38

COOLING

DESCRIPTION

DESCRIPTION - COOLING SYSTEM

The cooling system components consist of a radia-

tor, electric fan motors, shroud, pressure cap, thermo-

stat, transmission oil cooler, water pump, hoses,

clamps, coolant, and a coolant reserve system to com-

plete the circuit.

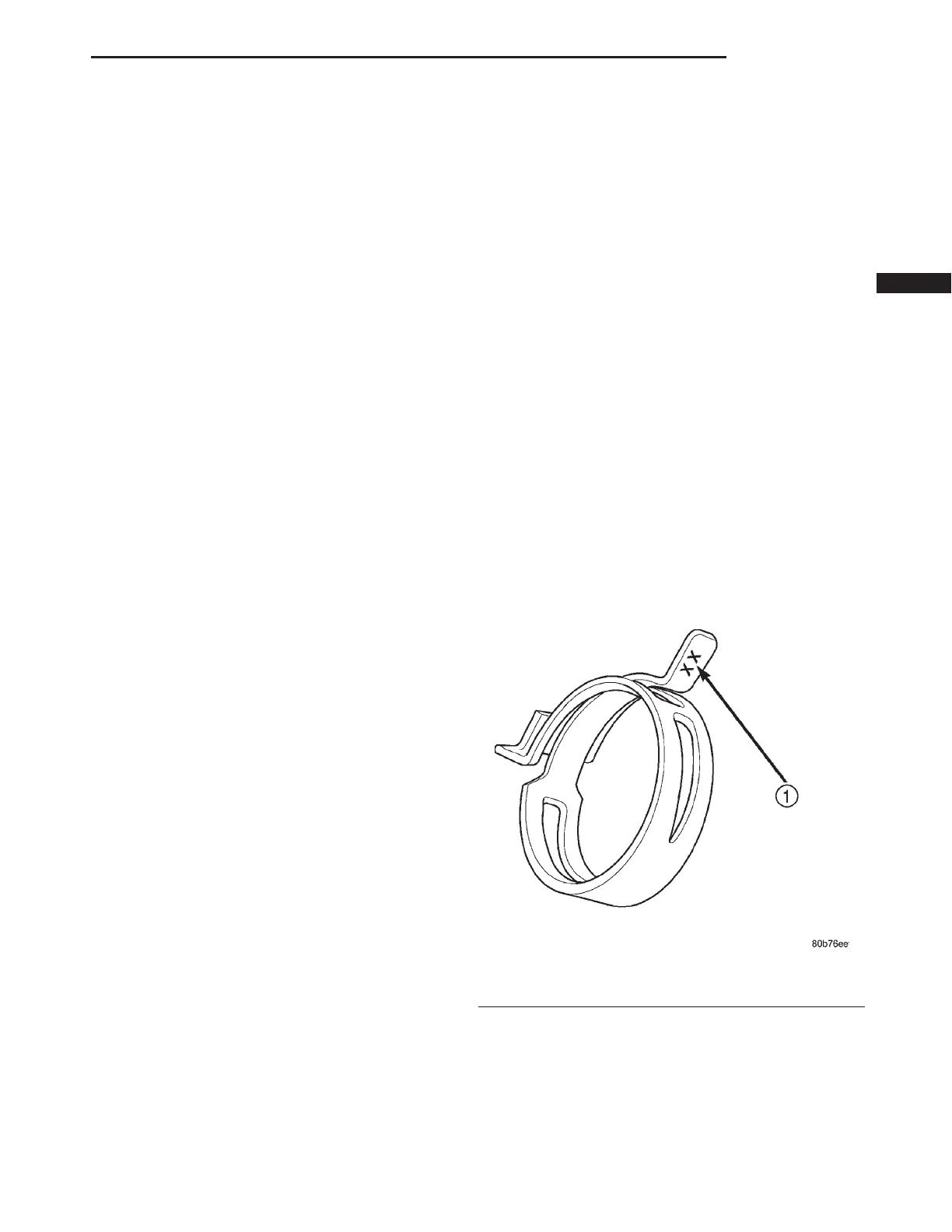

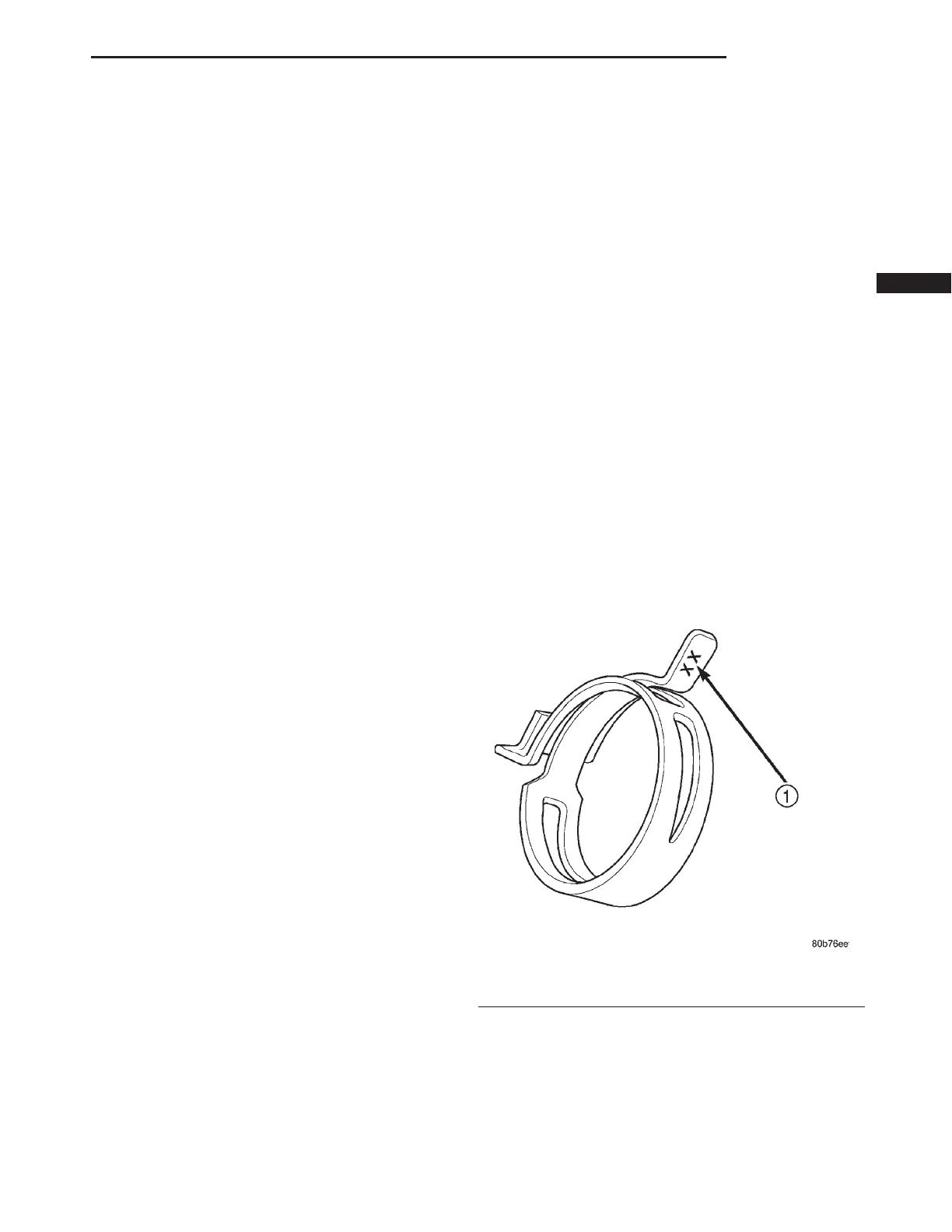

DESCRIPTION - HOSE CLAMPS

The cooling system uses spring type hose clamps.

If a spring type clamp replacement is necessary,

replace with the original Mopart equipment spring

type clamp.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only a original equipment clamp

with matching number or letter (Fig. 1).

Fig. 1 Spring Clamp Size Location

1 - SPRING CLAMP SIZE LOCATION

RS COOLING 7-1

Loading...

Loading...