Menu 3

Parameter

structure

Keypad and

display

Parameter x.00

Parameter description

format

Advanced parameter

descriptions

Serial comms

protocol

Performance

50 Mentor MP Advanced User Guide

www.controltechniques.com Issue Number: 4

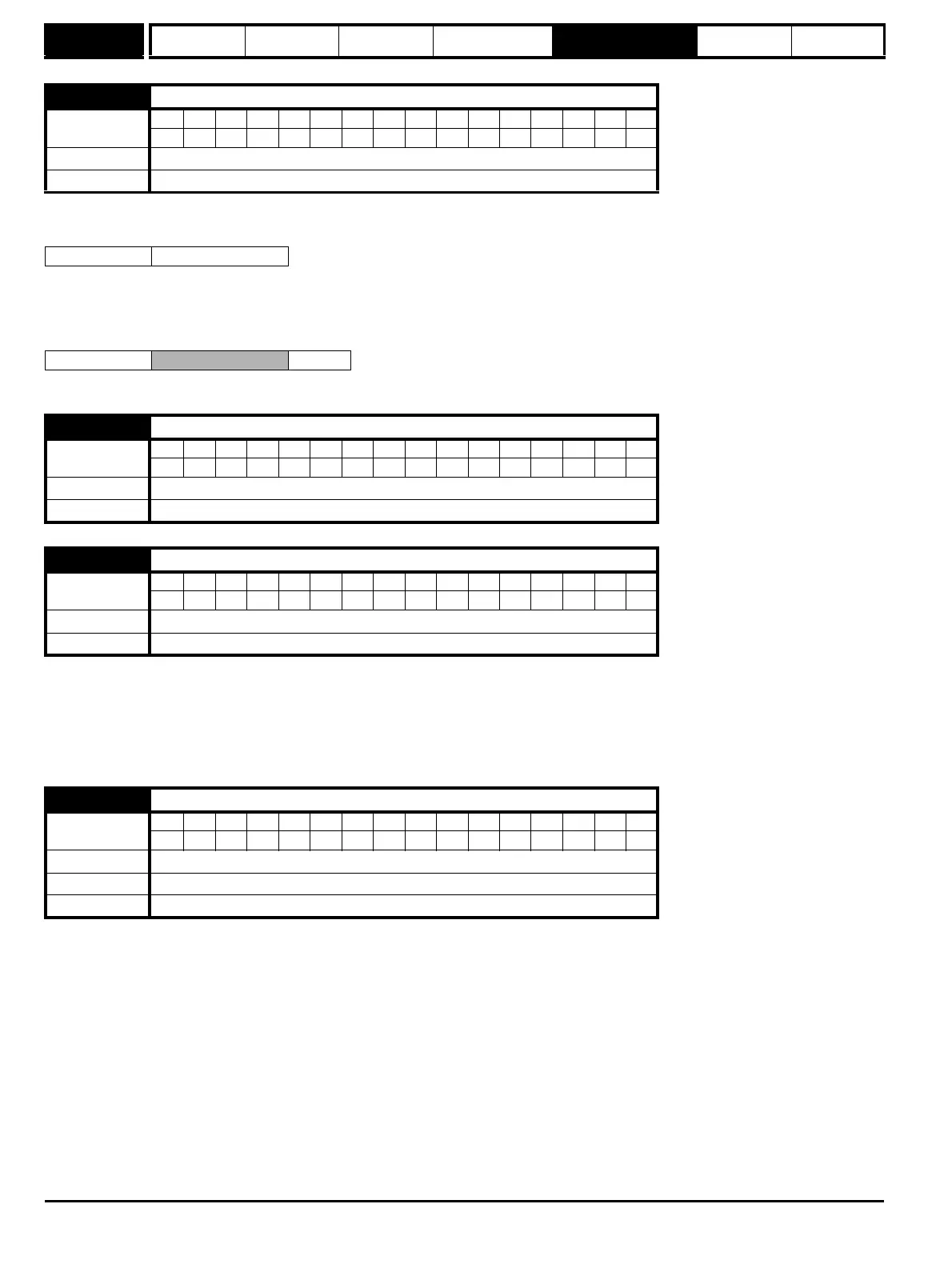

These parameters effectively give the encoder position with a resolution of 1/2

16

ths of a revolution as a 32 bit number as shown below.

Provided the encoder setup parameters are correct, the position is always converted to units of 1/2

16

ths of a revolution, but some parts of the value

may not be relevant depending on the resolution of the feedback device. For example a 1024 line digital encoder produces 4096 counts per

revolution, and so the position is represented by the bits in the shaded area only.

When the encoder rotates by more than one revolution, the revolutions in Pr 3.28 increment or decrement in the form of a sixteen bit roll-over counter.

An incremental digital encoder may have a marker channel. When this channel becomes active it may be used to reset the encoder position and set

the marker flag (Pr 3.31 = 0), or just to set the marker flag (Pr 3.31 = 1). The marker flag is set each time the marker input becomes active, but it is not

reset by the drive, and so it must be cleared by the user.

If Pr 3.35 is set to zero the marker system operates in a conventional manner and only resets the position (Pr 3.29) and not the turns (Pr 3.28) on a

marker event. If Pr 3.35 is set to one the whole position (Pr 3.28 and Pr 3.29) are reset on a marker event. The full reset mode allows the marker to

give a form of registration where the marker event defines zero position.

This parameter has a different function depending on the type of encoder selected with Pr 3.38 and Pr 3.39.

It is sometimes desirable to mask off the most significant bits of the revolution counter of encoders. This does not have to be done for the drive to

function correctly. If Pr 3.33 is zero the revolution counter (Pr 3.28) is held at zero. If Pr 3.33 has any other value it defines the maximum number of

the revolution counter before it is reset to zero. For example, if Pr 3.33 = 5, then Pr 3.28 counts up to 31 before being reset.

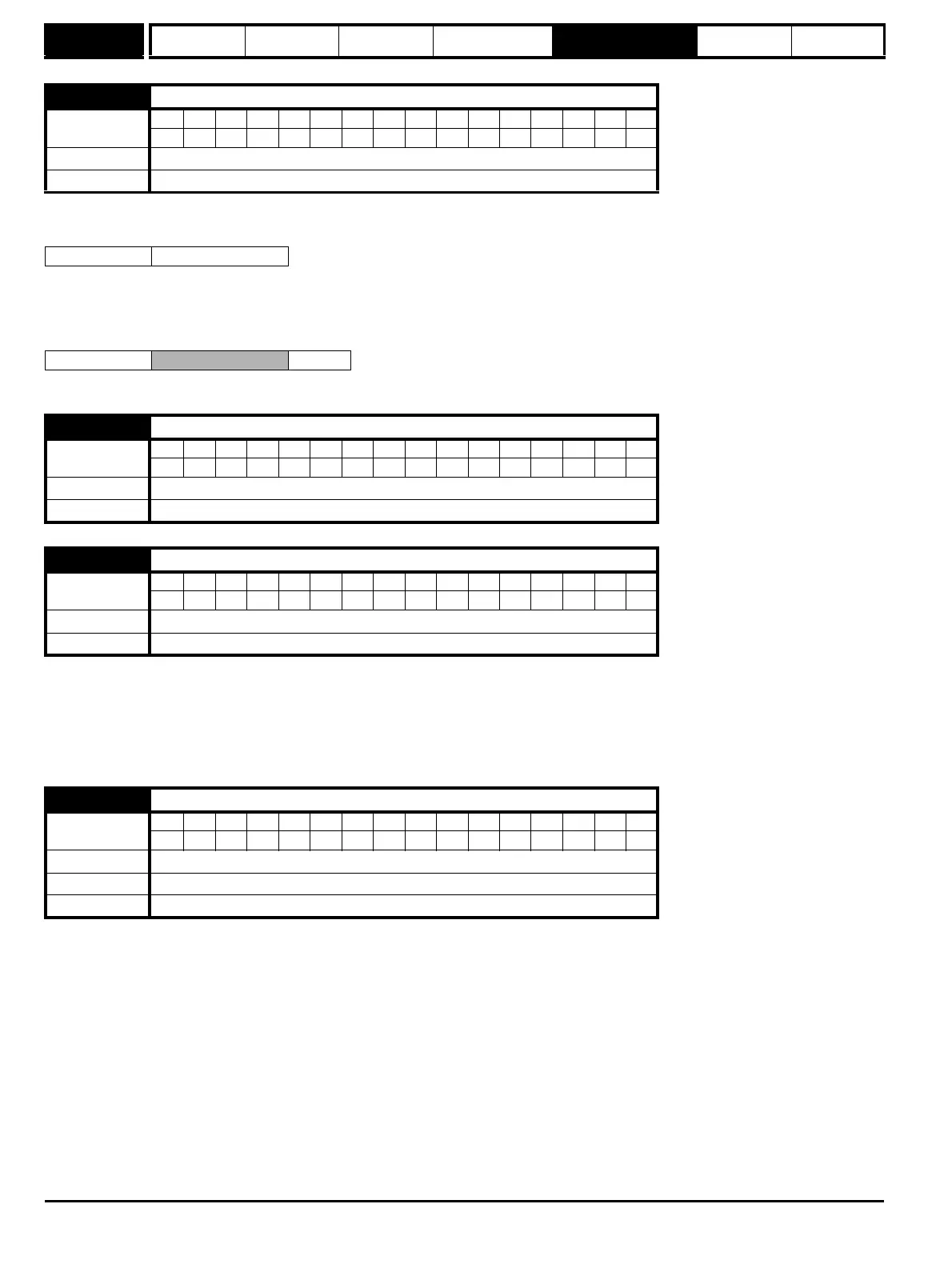

3.29

Drive encoder position

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

11111

Range

0 to 65,535 (1/2

16

ths of a revolution)

Update rate 4 ms write

31 16 15 0

Revolutions Position

31 16 15 4 3 0

Revolutions

Position

3.31

Drive encoder marker position reset disable

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

111

Default 0

Update rate Background read

3.32

Drive encoder marker flag

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

111

Default 0

Update rate 250 μs write

3.33

Drive encoder turns bits

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

111

Range 0 to 16

Default 16

Update rate Background read (Only has any effect when the drive is disabled)

Loading...

Loading...