5-16

Copyright 2017 Cummins Inc.

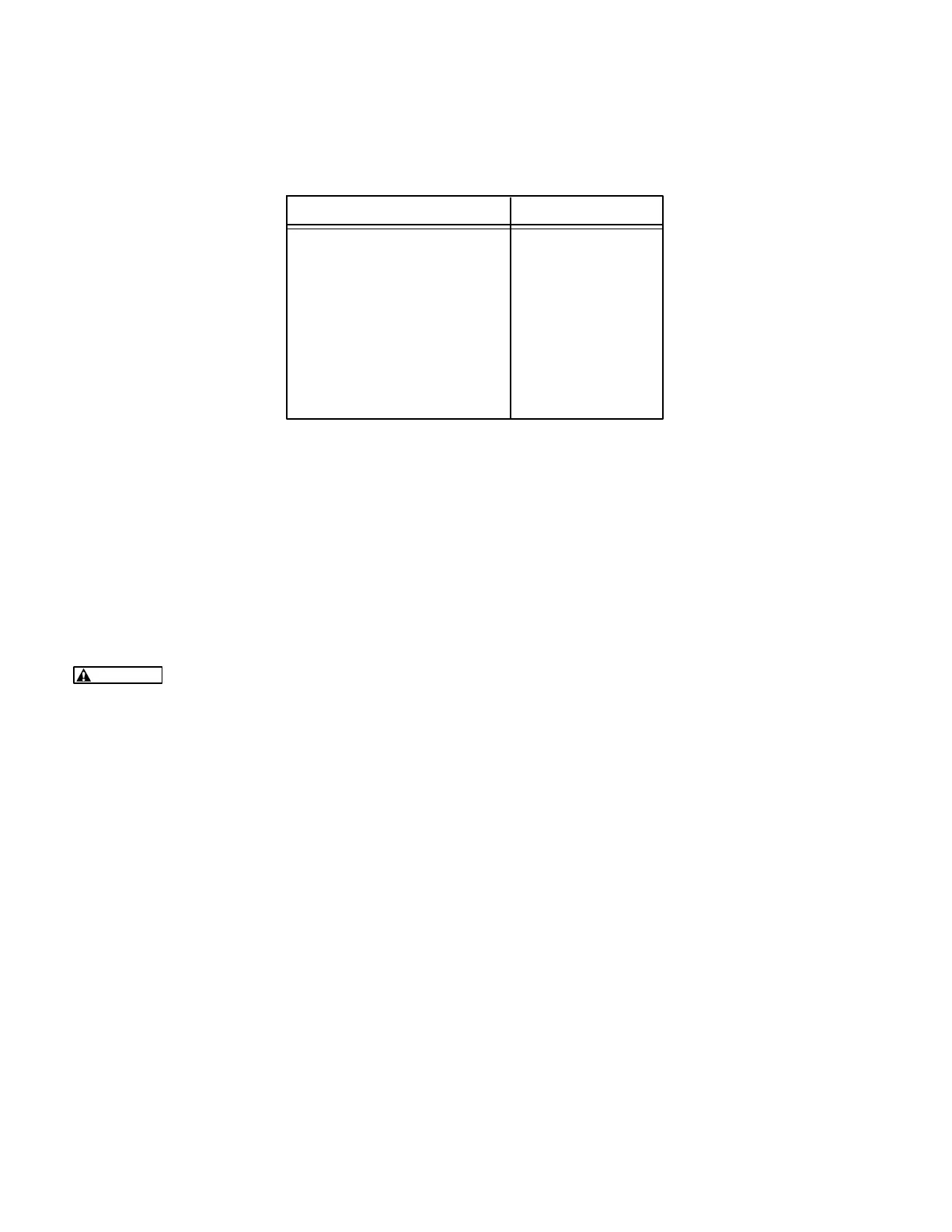

Setup Menu

The SETUP submenus permit selection of several

configuration and operation options. Setup option

defaults are listed in Table 5-2.

TABLE 5-2. SETUP DEFAULTS

SELECTION DEFAULT

CYCLE CRANK ON

SYSTEM OF UNITS IMPERIAL

*RACK POSITION (CF1) WARN

*GRND FAULT (CF2) WARN

*DAY TANK (CF3) WARN

*HIGH GEN TEMP (CF4) WARN

EGT L NO

EGT R NO

LOW COOLANT SHTD

LANGUAGE ENGLISH

* Default display messages for customer faults (CF) 1

through 4. To change the customer fault mes-

sage(s) or select the desired fault condition (WARN

or SHTD), refer to heading Edit Customer Fault

Messages.

The facing page shows a block representation of

the SETUP submenus, which is the fourth of four

SETUP/CAL menus. If you press the button next to

the “>>” in the Main menu display, the VERSION/

SETUP/CAL submenu will appear.

CAUTION

Improper calibration or adjustment

of the PowerCommand control can cause

equipment malfunction or damage. Calibration

and adjustment must be performed by techni-

cally qualified personnel only.

SETUP submenu: The SETUP submenus are in-

tended for qualified service personnel only. For this

reason, a three-digit access code must be entered

before you can proceed to those menus.

Select SETUP/CAL. The display will show the EN-

TER CODE submenu. Enter the access code (574)

as previously described in this section.

From the DISPLAYS/METERS submenu, press the

button next to the “>>” in the display to move to the

GOV/REG/SETUP submenu. Select SETUP to

proceed to the SETUP submenus or “>>” to pro-

ceed to the RACK TEST submenus.

Use the buttons next to the “

” symbols to toggle

the setup options. Press the button next to the “>>”

in the display to move to the next adjustment.

If the cycle cranking option is selected, the menu will

prompt for the selection of cycle number (3, 4, or 5)

and crank and rest times (7 to 20 seconds).

An in-line engine that has the EGT (exhaust gas

temp.) option, select “YES” for EGT L and ’NO” for

EGT R.

RACK TEST submenu: The RACK TEST subme-

nu is used to initiate the rack position diagnostic

test. This test is used to determine if the PCC is

properly controlling the rack position of the actua-

tors. To initiate this test, the Run/Off/Auto switch

must be set to the Off position.

When exiting this test or if the Run/Off/Auto switch

is moved to either the Run or Auto position, the PCC

software will re-initialize the governor duty cycle to 2

(0%) and allow the engine starting sequence to pro-

ceed as normal.

To perform the rack test, refer to the Rack Position

Fault/Test Procedure in Section 4.

TORQUE ADJ %DC submenu: This submenu is

used to adjust the engine torque through the digital

display to compensate for engine/electronic varia-

tions. If the generator set is not providing the name

plate kilowatt rating, the torque limit can be adjusted

at this menu. Refer to Engine Torque Adjustment in

this section for a detailed description of how to per-

form this adjustment.

Edit Customer Fault Message(s): The four cus-

tomer fault messages shown in Table 5-2 are edit-

able. Customer Fault 1 is reserved for the RACK

POSITION fault. Do not modify this fault name or

change the fault condition (

WARN to SHTD).

To enter the desired customer fault message, press

the button next to the “>>” in the display to display

Loading...

Loading...