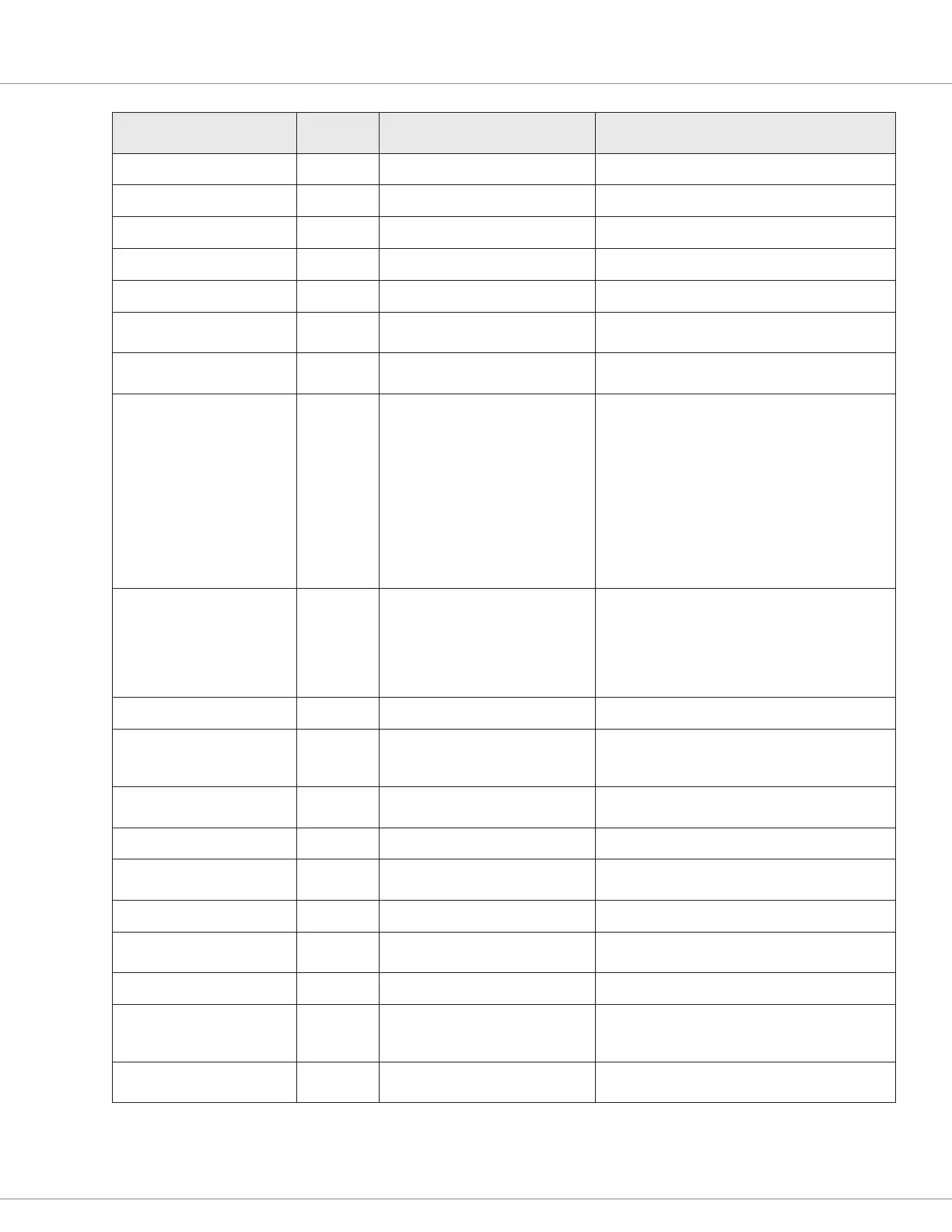

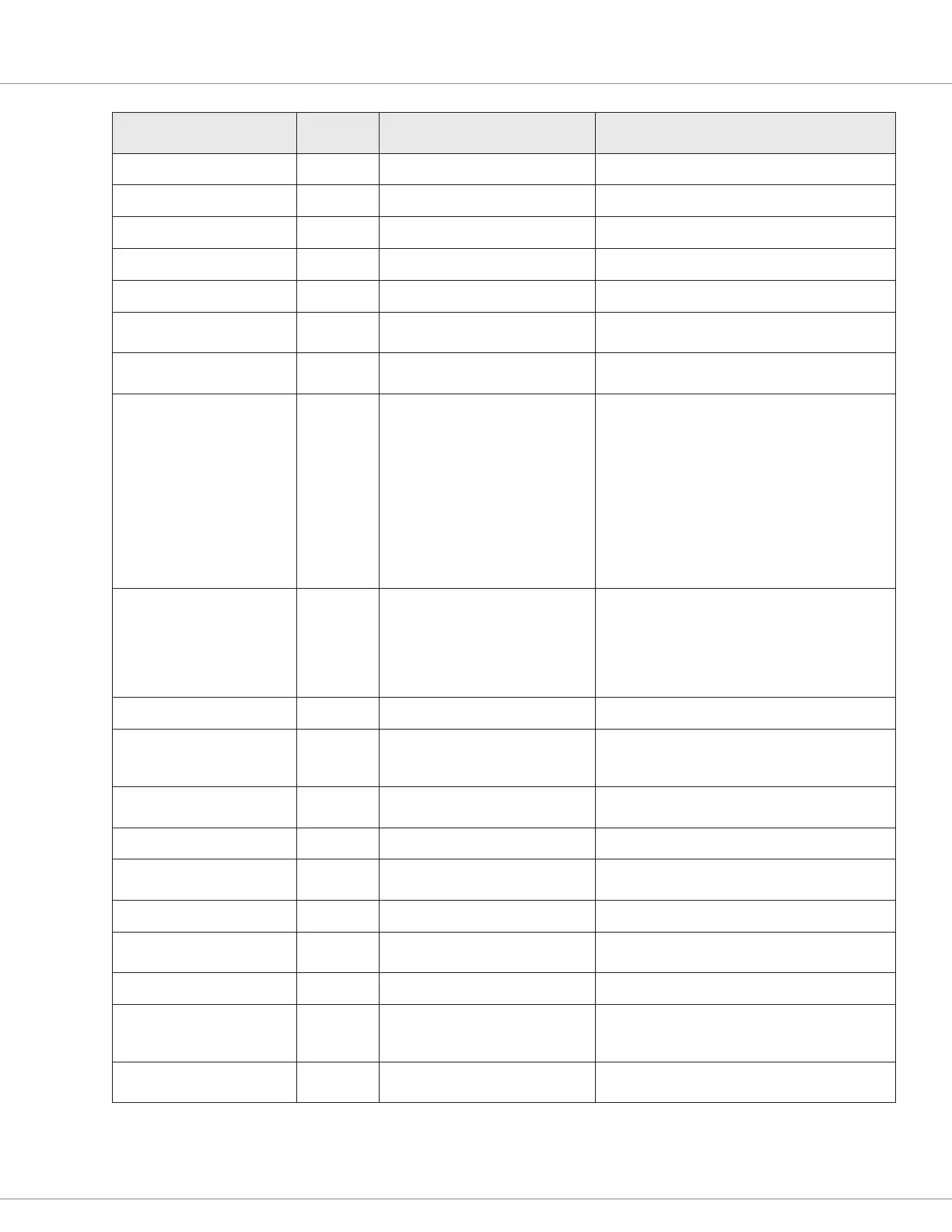

APPENDIX A — VCL FUNCTIONS

pg. 123

Return to TOC Curtis Model 1351 – December 2018

Function Name

new/unique to 1351 = (✔)

Arguments Short Comment Description

Get_Transmit_Status 1 (Handle) VCL_FUNCTION get_transmit_status

Clear_Transmit_Status 1 (Handle) VCL_FUNCTION clear_received_transmit_status

Get_Receive_Timeout 1 (Handle) VCL_FUNCTION get_receive_timeout

Get_Receive_ID 1 (Handle) VCL_FUNCTION Get the received arbitration ID

Clear_Receive_Timeout 1 (Handle) VCL_FUNCTION clear_receive_timeout

Assign_CAN_Mailbox 2 (port, function) Mailbox_handle: Assigned a value to identify the

mailbox that is assigned

Automate_Copy 3 Copy a Variable to another location

automatically

This function copies a variable from source to

destination

Automate_Block_Copy 4 Copy a block of Variables to

another location automatically

This function allows you to copy a sequential

block of variables from one location to another

location. The source and destination blocks

cannot overlap. The source and destination blocks

full range must be within the variable table,

otherwise a PT_RANGE error will be issued. If

you want to disable automatic copying, simply

set all parameters, except the ID, to zero (e.g.,

automate_block_copy(CPY3,0,0,0). If you do

not set the length to zero, then it is likely that a

PT_RANGE error will occur.

Automate_Limited_Block_

Copy

9 Copy a block of Variables to

another location automatically

This function allows you to copy four variables

from one location to another location. The source

and destination address for each variable to

transfer must be specied. A source/destination

pair will be ignored (i.e., not transferred) if either

the source or the destination value is set to zero.

Setup_Delay 2 Setup a Time Delay This function installs a new time delay

Setup_Delay_PreScale 2 Setup a Delay Timer’s pre-scale This routine setups up a pre-scale for time delay

block. The default pre-scale is 1 (i.e., the timer

counts down at a 1ms rate).

Automate_Filter 5 Filter a value This function initiates ltering on the selected

variable

Setup_Limit 3 Setup a Limit Function This function installs new value for a limit block

Automate_Limit 3 VCL - Automate a Limit Function This function sets one or more of the values in a

limit block to be automatically updated

Set_Limit 2 Set the Limit Value This function installs new value for a limit

Get_Limit 2 Get the Limited Value This function returns the input ‘clamped’ by the

limit

Setup_Map 16 Setup a map This function species a map.

Automate_Map 2 Set the mapping up to be done

automatically

This function allows you to set up a map that runs

automatically. The ‘source’ is the variable that will

be mapped.

Get_Map_Output 2 Interpolate within a 2D table of N

entries

This function maps the input variable to a new

value using the specied map.

Loading...

Loading...