2 — INSTALLATION SPECIFICATIONS AND WIRING

Curtis Model 1351 – December 2018

Return to TOC

pg. 24

Encoder Inputs

e 1351 System Controller accepts two position encoder inputs labeled as Encoder 1 and Encoder 2.

ree types of encoders can be connected:

• Quadrature Encoders with Open Collector outputs

• Sine/Cosine Position sensors

• Sawtooth Position transducer

Each type of encoder requires unique wiring and setup parameters, yet the result is the same: position

and speed measurements. Aer selecting the encoder Type, its corresponding parameter set will

become available, otherwise it is hidden. Notice that Encoder 1 shares its inputs with the High Speed

Digital Inputs (see above), thus it cannot be used as both the encoder and the high-speed inputs

simultaneously. For each type of encoder, the input signals are mathematically converted to position

and speed. In all cases, the connections are referenced to the controller’s I/O ground (pin 8).

Quadrature Encoders

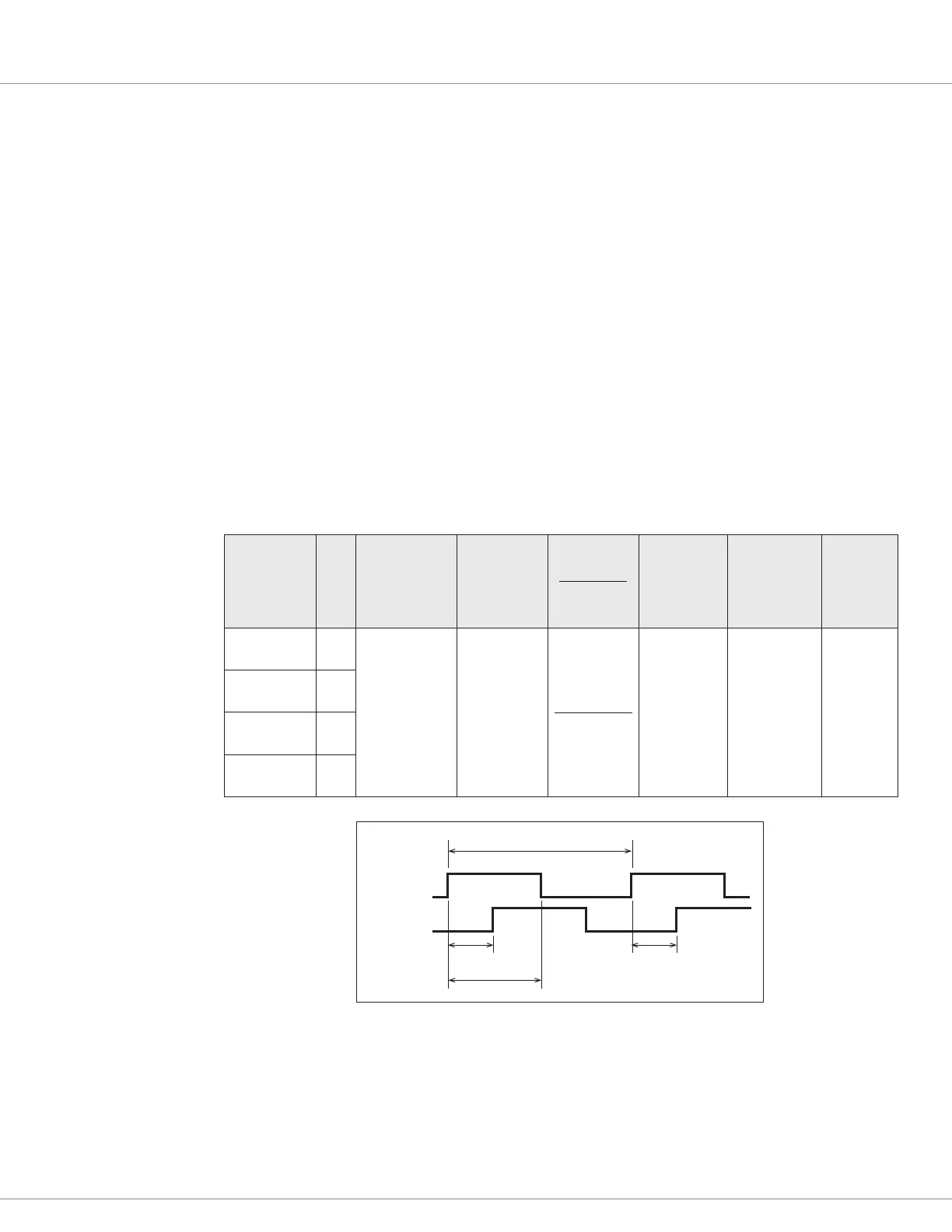

Table 13 Quadrature Encoder Inputs

Signal Pin

Input Voltage

Range

Logic

Threshold

Pull-Up

Resistance

Input

Impedance

Maximum

Frequency

A-B Phase

Range

Phase Duty

Cycle

ENC 1A

(Analog 4)

15

0 – 5 V

Rising edge=

2.9 V max

Falling edge=

2.0 V min

2 kΩ to 5 V

> 115 kΩ

15 kHz 90° ± 30°

50 % ±

10 %

ENC 1B

(Analog 3)

14

ENC 2A

(Analog 2)

2

ENC 2B

(Analog 1)

1

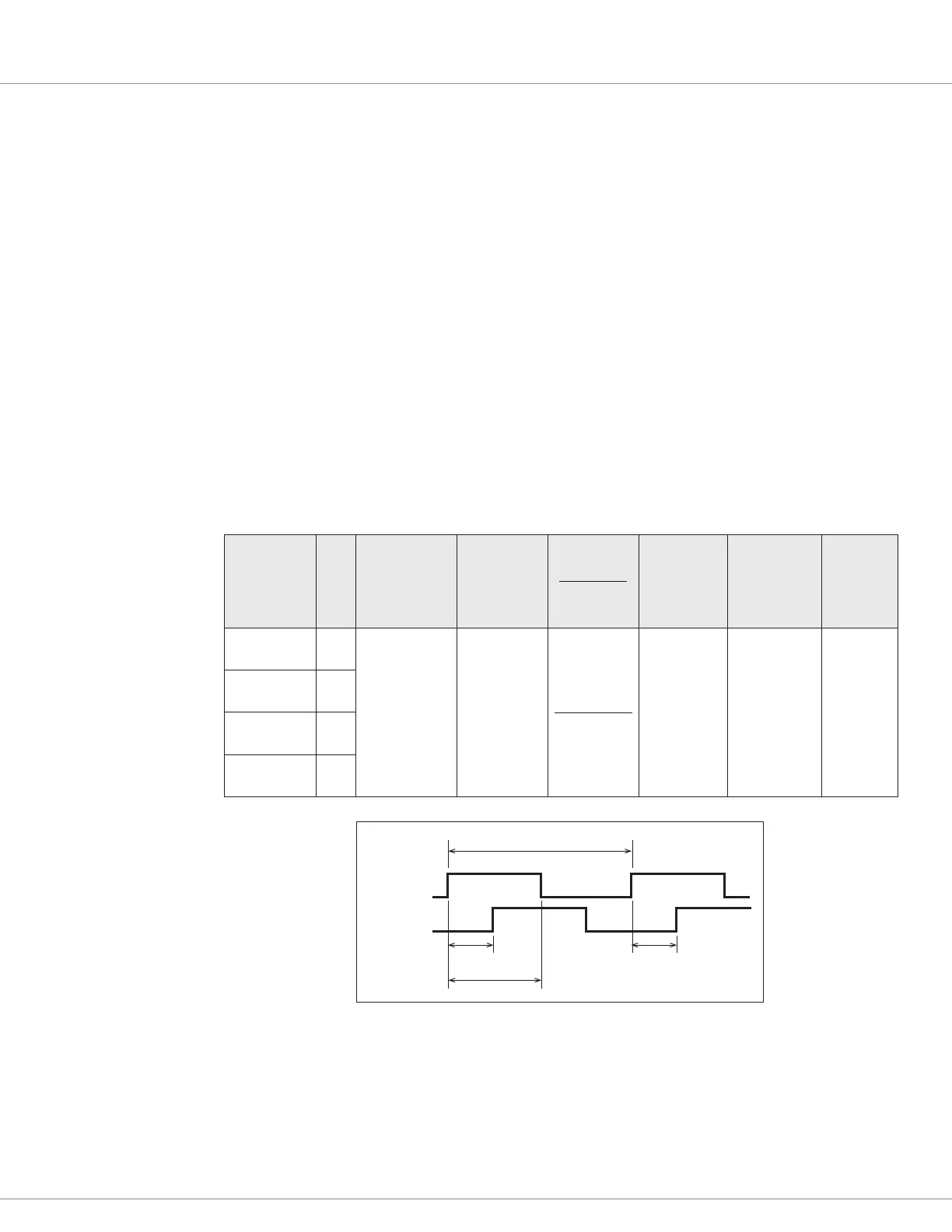

Channel A

Channel B

360° electrical (1 cycle)

>10 μs90° ±30°

180° ±18°

These quadrature encoder signal tolerances must be maintained throughout the application’s

operating conditions, including voltage and temperature, as well as speed and torque ranges when

applied to a motor. A parameter setting is available for channel A and B direction—A before B or B

before A.

Loading...

Loading...