APPENDIX A — VCL FUNCTIONS

Curtis Model 1351 – December 2018

Return to TOC

pg. 122

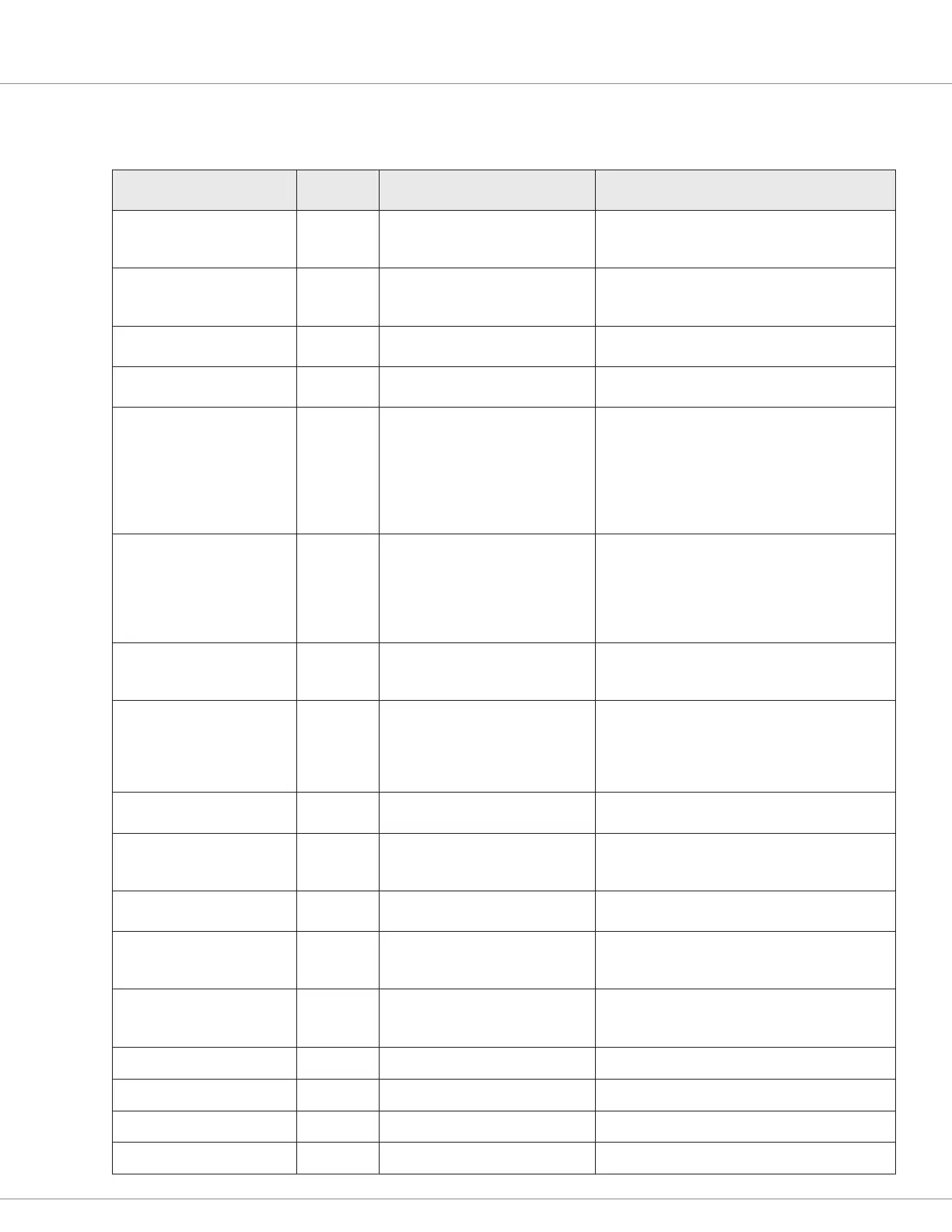

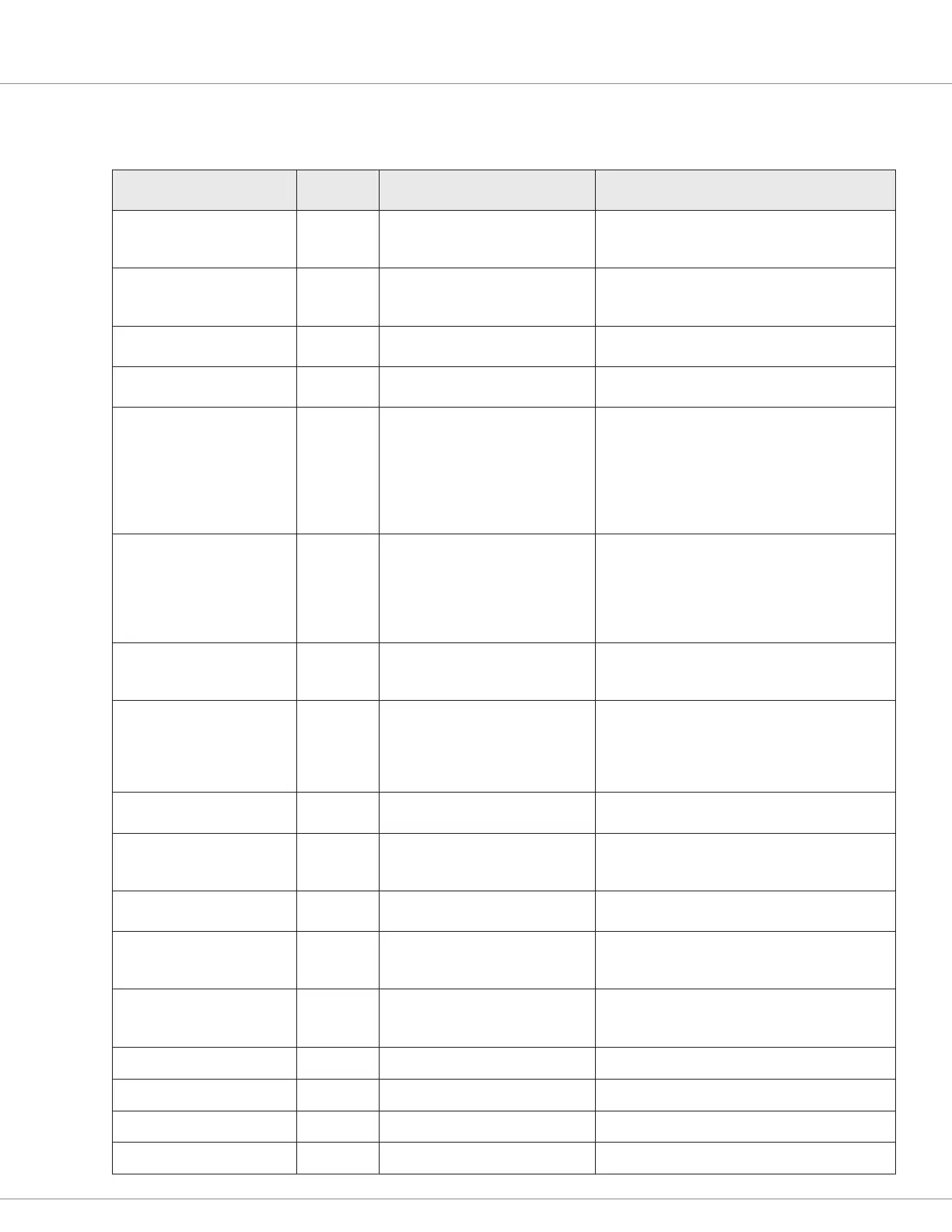

APPENDIX A — VCL FUNCTIONS

Function Name

new/unique to 1351 = (✔)

Arguments Short Comment Description

Map_Two_Points 5 2 Point Interpolation Routine This routine interpolates between two points Y1

and Y2 based upon an input x. Interpolating based

on X1 and X2

Battery_Compensate 1 This function is used for compensating a variable

with battery voltage using the nominal battery

setting

Automate_ABS 2 Run the absolute value function

automatically

This function returns the absolute value of its

input

Get_ABS 2 Get the Absolute Value of the Input This function returns the absolute value of the

input variable.

Send_Mailbox 1 Request that a Message Buffer be

sent

This function forces the mailbox contents to be

sent out. This is necessary for any mailboxes that

have been setup with the C_EVENT constant.

The mailbox must have been setup and its data

pointers dened (setup_mailbox and setup_

mailbox_data functions called) before using this

function!

Setup_CAN_Transmit_

Mailbox

6 (Handle, ID_high, ID_low, Extended,

Service, Rate)

Setup the General Parameters for a Transmit

Mailbox. This function sets up the initial

parameters for a mailbox. This function MUST BE

called before dening the data for the mailbox

(see setup_mailbox_data) or trying to use the

mailbox.

Setup_CAN_Recieve_

Mailbox

10 (Handle, ID_high, ID_Low, Mask_

High, Mask_Low, Extended, Reply,

Timeout, Handshake)

Setup the General Parameters for a Mailbox

Setup_CAN_Receive_Data 4 (Handle_Id, Data, Length, Endian) Dene the pointers used with a Message Buffer.

This function is used to dene the ‘data pointers’

for a given mailbox. The setup_mailbox function

MUST HAVE BEEN called before dening the data

with this function.

Setup_CAN_Transmit_Data 4 (Handle, Data, Length, Endian) This function is used to dene the ‘data pointers’

for a given mailbox.

Enable_Receive_Mailbox 1 (Handle) Enable all the CANopen standard processing

VCL_FUNCTION Enable_receive_mailbox; Enable

VCL Receive Mailbox.

Disable_Recieve_Mailbox 1 (Handle) VCL_FUNCTION Disable_receive_mailbox; Disable

VCL Receive Mailbox.

Enable_Transmit_Mailbox 1 (Handle) Enable all the CANopen standard processing VCL_

FUNCTION enable_transmit_mailbox ; Enable VCL

Transmit Mailbox

Disable_Transmit_Mailbox 1 (Handle) disable_transmit_mailbox :: VCL - Disable

CANopen Processing VCL_FUNCTION disable_

transmit_mailbox ; Disable VCL Transmit Mailbox

Get_Received_Counter 1 (Handle) VCL_FUNCTION get_received_counter

Get_Transmit_Counter 1 (Handle) VCL_FUNCTION get_transmit_counter

Get_Received_Status 1 (Handle) VCL_FUNCTION get_received_status

Clear_Received_Status 1 (Handle) VCL_FUNCTION clear_received_status

Loading...

Loading...