2 — INSTALLATION SPECIFICATIONS AND WIRING

Curtis Model 1351 – December 2018

Return to TOC

pg. 26

Sawtooth Position Transducer

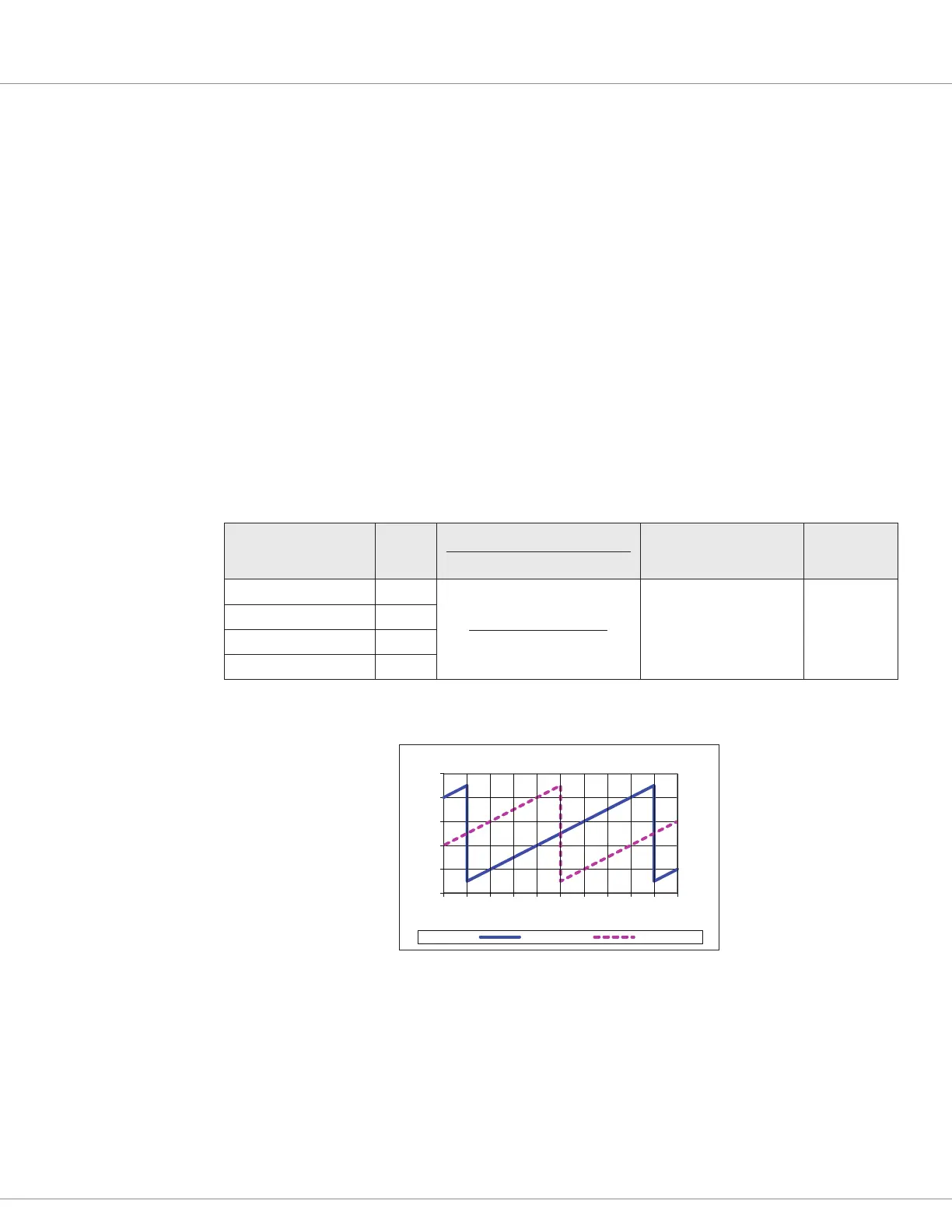

e sawtooth transducer has two analog signals that ramp up as its sha rotates through 360 degrees.

As illustrated below, the signals are oset by 180 degrees. Unlike the sine/cosine sensor, each signal

provides an absolute indication of position, thus requiring a dierent set of setup parameters. e

signal voltage range must be set and the voltage that represents 0 degrees is required. If the analog

signals go outside the specied ranges for >60mS, a fault is declares. Also, if the position calculated

using the channel A is outside a tolerance parameter compared to channel B for >60mS, a fault will

be declared. e tolerances must be maintained throughout the application’s operating conditions,

including voltage and temperature, along with speed and torque ranges when applied to a motor.

As illustrated in the sawtooth waveform diagram, connect the sensor with one waveform cycle per

mechanical revolution. Channels for A and B are parameter selectable for direction—A before B or

B before A.

An example application is tracking linear-travel and position such as fork-reach where one revelation

covers the range from retracted to full extend. Another is for steering angle where one steering-wheel

rotation equates to one cycle (360°) of the sawtooth waveform(s).

Table 15 Sawtooth transducer

Signal Name Pin

Operating Voltage

Signal Range (peak to peak)

Max. Frequency

Input

Impedance

ENC 1A (Analog 4) / B 15

0 – 10 (min – max)

0 – 10.0 V

200 Hz > 115 kΩ

ENC 1B (Analog 3) / A 14

ENC 2A (Analog 2) / B 2

ENC 2B (Analog 1) / A 1

A B

0

1

2

3

4

5

-225-180-135 -90 -45 0 45 90 135 180 225

Volts [ V ]

Position [°]

Sawtooth Waveform

Loading...

Loading...