2 — INSTALLATION SPECIFICATIONS AND WIRING

pg. 13

Return to TOC Curtis Model 1351 – December 2018

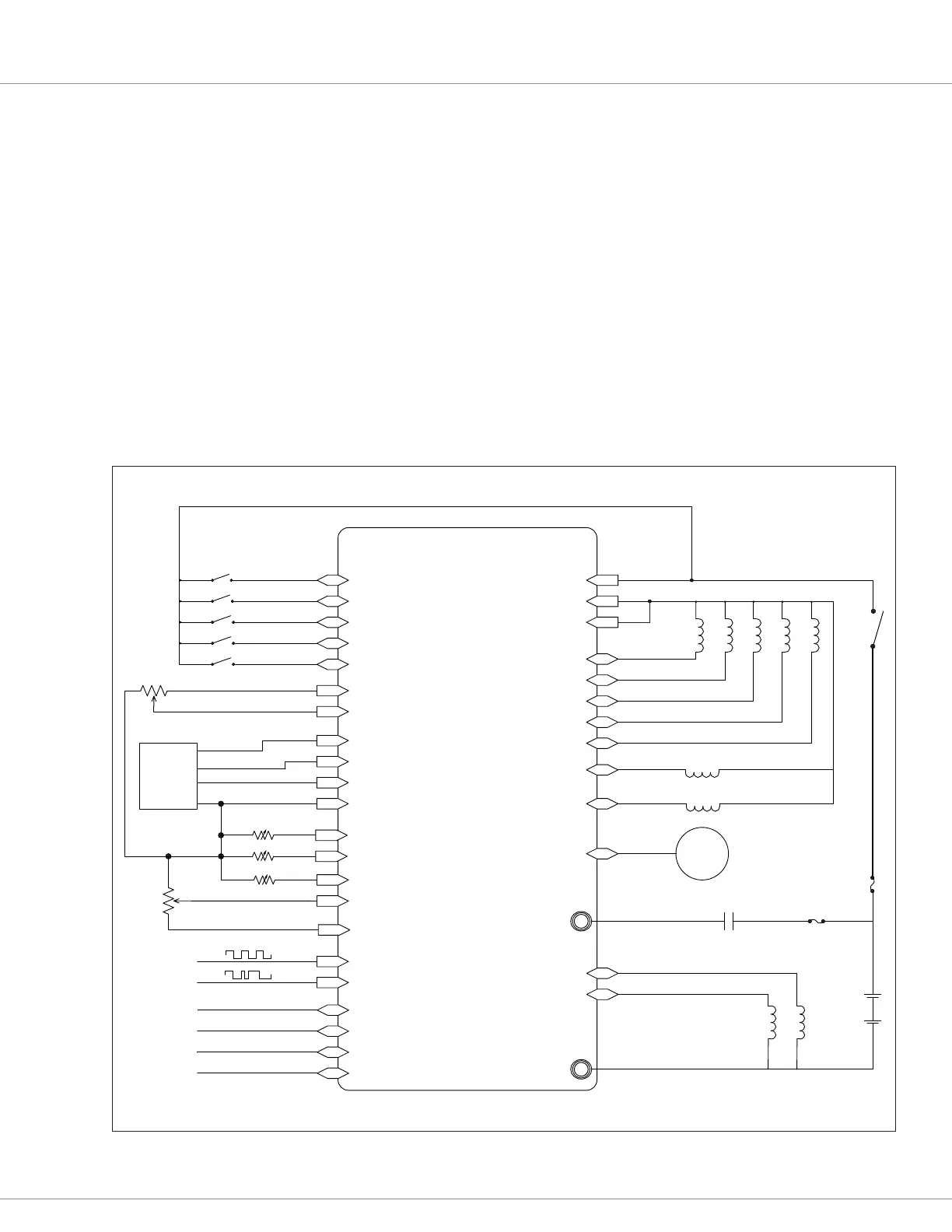

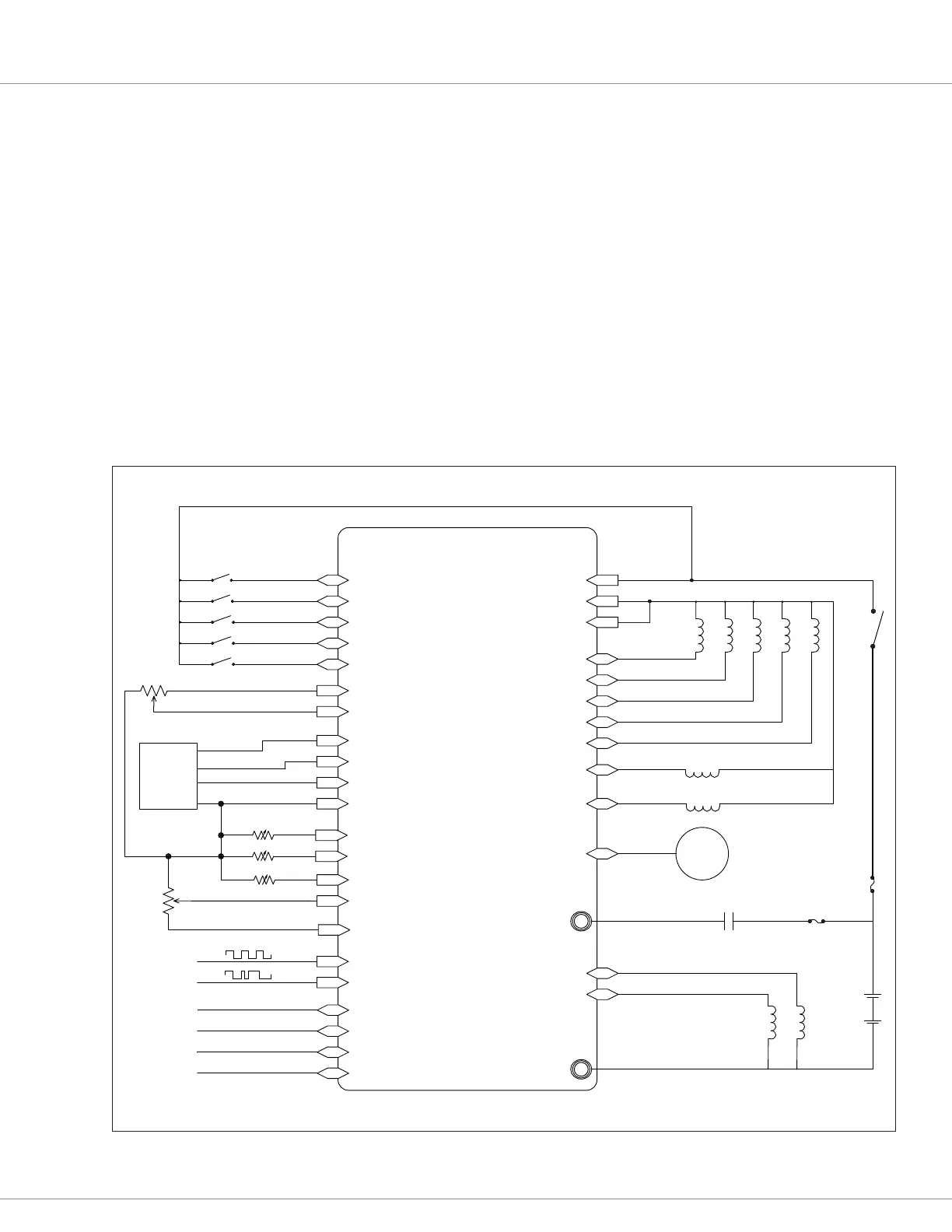

THE SYSTEM CONTROLLER’S WIRING DIAGRAM (EXAMPLE)

e 1351’s Inputs and Outputs (I/O) can easily conform to a wide range of applications. Use this chapter

and Chapter 3’s parameters information for insight into using and setting up each type of I/O. Figure

4 is the example-wiring diagram using the 1351 as an ICE driven hydraulic systems controller. In this

example, the Li/Lower and Steer Angle potentiometers connections are 3-wire potentiometer inputs,

while the control of the main contactor is by another device. Figure 4’s connections are representative

of just some of the possible 1351 System Controller wiring congurations.

Note: In cases where an application’s wiring and I/O usage deviates from the wiring shown in Figure 4,

it is up to the OEM to evaluate the overall system safety. Always ensure a conguration is thoroughly

tested and veried for the application.

Figure 4

Example Wiring Diagram

1351 System Controller

Encoder

+12V

+5V

KSI

11

12

Gauge

{

{

Engine Temp

33

4

3

6

5

10

2

1

8

29

30

31

32

21

20

22

9

14

25

34

28

27

26

24

13

35

23

17

16

Oil Temp

Oil Pressure

15

19

18

(B+ for the PWM drivers)

}

Loading...

Loading...